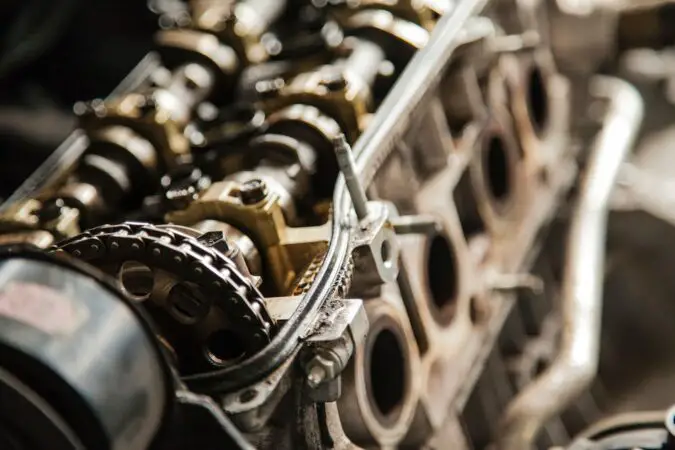

As internal combustion engines get older, they are more susceptible to a variety of potential problems. Some of these faults are relatively small in scope. However, others can cause serious drivability problems, such as a blown head gasket which frequently calls for expensive repairs. Of course, this ain’t a desirable situation.

A head gasket serves as the seal between the engine block and cylinder head in an internal combustion engine. Its main function is to seal the combustion gases inside the cylinders and prevent coolant or engine oil leaks. Head gasket leaks may result in overheating or poor engine performance.

One of the most troublesome problems for drivers whose engines have started to age is a blown head gasket. Unfortunately, head gasket repairs are rarely quick or inexpensive. This fact alone is a frequent cause of worry for those dealing with such problems.

Continue reading to find out more about the function of an engine’s head gasket and the different signs and symptoms that point to a blown head gasket.

Head Gasket

The seal between the cylinder head and engine block in an internal combustion engine is called a head gasket. This seal stops coolant and oil from entering an engine’s combustion chambers as well as the escape of combustion fumes from the cylinders.

The head gasket experiences a wide variety of temperatures because of its proximity to hot and cold engine parts. This includes the combustion chamber’s intense heat to the cooling system’s frequently chilly temperatures. The head gasket may eventually have surface scratches as the effects of temperature variations wear off over time.

Depending on the precise configuration of an engine’s cylinders, each engine has 1 or 2 head gaskets. One head gasket is present in an inline engine because there is only one cylinder head. On the other hand, “V” layout engines have two separate cylinder heads, and as a result, two head gaskets.

In the past, production engines commonly came equipped with copper head gaskets or a variety of composite gaskets, which were typically made of graphite or asbestos. Today, Multi-Layer Steel (MLS) head gaskets make up the majority of production head gaskets. These gaskets consist of two to five layers of thin steel, typically covered in a rubberized coating.

The head gasket(s) of an engine is secured in place between the engine block and heads using carefully torqued head bolts. These bolts frequently have a torque-to-yield design, which stretches as they are tightened to create the best clamping seal.

The head bolts on an engine are also torqued in a specific manner, which frequently entails starting with the centermost bolts on each head and moving outward.

Blown Head Gasket

When a head gasket’s structural integrity has been jeopardized, it is referred to as having a “blown head gasket.” The block deck and cylinder heads of an engine cannot be properly sealed together because of this defective segment of the head gasket. This causes a leak, which might show up in several ways.

A head gasket’s specific point of failure might result in a variety of problems, depending on the situation. Coolant or oil could be forced internally or externally into one or more cylinders of an engine. Additionally, the displacement of oil and coolant into one another might cause fluid mixing.

Additionally, combustion gases may leak from a failing head gasket and end up in the crankcase or the cooling system of an engine. Alternatively, a burst head gasket might cause the combustion gases from one cylinder to leak outside the engine or into another cylinder nearby.

Any form of head gasket leak can cause a range of drivability-related problems. This can get worse as the severity of the leak increases. Overheating and compression loss are two of the most dangerous side effects of a ruptured head gasket.

What Causes A Blown Head Gasket

Prior to repairs or installing a new gasket in the event of a head gasket failure, it is crucial to determine the source of the problem. Otherwise, you run the risk of damaging the new gasket.

A quality head gasket that was otherwise expertly placed can be ruined by one or more engine issues. Knowing the operational state before a head gasket failure enables you to locate the issue’s root cause and fix it.

The parts that follow go through numerous faulty engine operating conditions and the possible causes of such faults. If not addressed in a timely manner, these concerns are known to affect the head gasket. The following information might be able to assist you in determining the cause of your vehicle’s issue.

If one or more of the aforementioned symptoms are present but your head gasket is still in good shape, you can make the appropriate repairs before you need to perform a more costly remedy.

1. Engine Overheating

One of the most frequent reasons for a head gasket failure may be overheating. An overheated engine can expose a gasket to temperatures that it was not designed to withstand. This causes the aluminum head to expand faster than usual and crash the head gasket. Overheating can substantially degrade a head gasket, even if it doesn’t immediately ruin it, and eventually lead to its failure.

There are multiple causes that could lead to overheating and those are listed below-

- Leaking cooling system

- Faulty radiator fan

- Malfunctioning EGR system

- Clogged radiator

- Thermostat stuck closed

- Failed water pump

- Loose serpentine belt

- Aged coolant in the system

- Lack of cooling system maintenance

- Using the wrong type of coolant

- Failure to properly mix antifreeze and water

- Faulty radiator cap

- Failed radiator hose

2. Irregular Combustion

Preignition or detonation may be a more frequent cause of head gasket failures than overheating. The flame that burns the air-fuel mixture in the combustion chamber spreads evenly and smoothly during normal combustion. A lean combination, excessive heat, or low-octane fuels, however, can interfere with this process.

Detonation occurs when the cylinder’s internal ignition process ignites too slowly. This enables pressure to build up and ignite a second ignition front at the mixture’s edge. This then knocks into the initial combustion process. The shock wave from the explosion creates internal engine vibration. This could result in engine knock and physical engine damage, including head gasket failure. Usually, detonation is caused by-

- Excessively lean air/fuel mixture

- Poor fuel distribution inside the cylinder

- Irregular ignition timing

- Faulty EGR valve

- Low octane fuel

On the other hand, preignition is the process of ignition that starts before the spark plug fires. Additionally, due to this circumstance, two combustion fronts collide causing a pinging sound.

Engine pinging, which is regarded as a less severe kind of knocking, is audible as a gentle tapping sound emanating from the engine. Engine pinging can also turn into dangerous detonation if it is not stopped. However, it is not as bad as detonation. Preignition is usually caused by-

- Carbon deposits in the chamber

- Overheated exhaust valve

- Glowing spark plug

- Faulty cooling system

- Poor engine lubrication

3. Hot Spots

Using the incorrect gasket for the job can potentially result in cylinder head gasket failure. Original head gasket problems have occurred in a number of different car types.

Hot spots may develop in some engine designs. For instance, hot spots in certain areas may result from engines with exhaust ports that are excessively close to one another. If the gasket isn’t reinforced in specific places, it may result in head gasket failure.

However, it may also occur if the factory-original head gasket has been changed. For instance, if the head or block surface was turned in the machine shop and the proper gasket was not used for the finish, the gasket may fail.

Some gaskets can even restore the space lost during the machining process and are designed to adequately fill minor flaws on the surface they are protecting. The purpose of this is to avoid tampering with the ignition timing, particularly in OHC (overhead cam) engines. Use the proper head gasket for the job if your block, cylinder head, or both need to be resurfaced.

4. Design Flaw

In overhead cam engines, the timing chain or belt must typically be removed in order to remove the front and top of the engine and gain access to the gasket. To access the head gasket on some makes and models, the majority of the engine must be taken apart. There are times when limitations in the engine architecture cause a head gasket to fail.

Therefore, in modern automobiles, maintaining the cooling system with high-quality fluid and top-ups is increasingly important. In modern engines, normal operating temperatures fall between 200-225 °F.

As a result, when a temperature gauge reaches the hot zone, the engine is extremely hot. The head gasket and cooling system may both be stressed beyond their typical limitations if the engine temperature increases above 240 °F. The impact is almost certain to occur if the engine temperature exceeds 260 °F.

5. Faulty Installation

During installation, mistakes might be made that lead to the head gasket failing. For instance:

- Reuse of worn-out head bolts.

- Using one or more head bolts that are broken.

- Failing to clean the surface of the head or the block before replacing the head gasket.

- Mounting the head bolts with the incorrect tightening method or sequence.

- Wrong application of sealant.

- Cleaning the mating surface of the head or block cylinder with abrasive pads.

Blown Head Gasket Symptoms

Blown head gaskets are not very frequent. However, they do happen frequently enough to highlight the significance of understanding the signs of such a situation. These signs can be swiftly identified so that a repair can be started and your car is back on the road as soon as possible.

A burst head gasket typically leaves a driver wondering what went wrong. The combustion chamber, the coolant system, or anything else could really be to blame. The fact that symptoms that resemble head gasket failure can occasionally result from other causes is the most perplexing. In some circumstances, an engine symptom may appear as a result of several engine problems.

A number of telltale symptoms may manifest when you have a faulty head gasket. The mixing of the various fluids is the cause of all of these symptoms. Even though the head gasket is blown, the fluids may not necessarily mix even in such cases.

Additionally, it does not mean that a blown head gasket will necessarily result in all of these symptoms. If you experience any of these signs, you should stop your automobile as soon as you can and have a mechanic inspect it.

1. White Smoke From The Exhaust

White smoke from the exhaust typically indicates that there is something unwanted in the combustion chamber or the exhaust. If a burst head gasket is the source of the white smoke, coolant or oil entering the combustion chamber is to blame.

There are a number of causes for white smoke to develop. Even though it doesn’t always point to a serious problem, you should be aware of it and look for the root of the problem.

2. Engine Overheating

The most typical sign of a blown head gasket is excessive engine heat. The coolant vaporizes when it enters the combustion chamber and is released from the exhaust afterward. The effect is that the coolant is quickly used up.

The engine overheats as a result of the lack of coolant. In addition to a lack of coolant, a burst head gasket can cause less effective power generation, which increases heating.

3. Milky-Colored Oil

By lubricating numerous key components in the engine compartment, the engine oil performs a significant function. Oil and water shouldn’t mix; if they do, the mixture will turn into a frothy liquid with a milky tint. The engine oil’s lubricating characteristics will almost completely disappear due to this unwelcome mixture of oil and coolant.

Check the oil filler cap to see whether there is any milky-colored, foamy liquid if you think the head gasket has blown. If it is, a blown head gasket is probably the blame. It is significant to note that oil and coolant could mix due to some other issue too. Therefore this issue might not be solely brought on by a blown head gasket.

Radiator caps may develop a mayonnaise-like layer as a result of oil leaking into the coolant system. It’s possible to see bubbles in the overflow tank as well. Hydrolocking the engine is another issue brought on by coolant leaking into the combustion chamber.

4. Blown Head Gasket Sound

In more severe circumstances, the engine will experience a significant loss of compression, which results in engine knocking. When you are at a standstill, you will also detect a harsh idle.

The engine might potentially stall in some circumstances. This is brought on by friction between moving parts that aren’t lubricated, which might result in lasting harm. A rough idle and engine knock are not always evidence of a blown head gasket. But they frequently are, just like the other symptoms mentioned.

Testing A Blown Head Gasket

Carbon dioxide testing is a reliable method of determining whether a head gasket is blown. This test looks for signs of combustion fumes in the coolant. The test is conducted using a device that makes use of a solution whose color changes when it comes into contact with carbon monoxide. The following are the steps:

- Reduce the radiator’s coolant level (to provide a testing air space).

- Warm up the engine (for improved accuracy).

- Utilize the tool to take samples of the fumes from the coolant.

- Mix the samples in the test solution.

If the solution turns yellow, the coolant has failed the test and there is an issue. Of course, the test isn’t always accurate, and CO2 may still be present in the coolant even if the solution doesn’t change color. However, the test is typically accurate in identifying an issue that is a sign of an unhealthy engine.

A cylinder head that has ruptured, which exhibits symptoms identical to those of a failing head gasket, is another issue that a CO2 test can possibly identify. A cylinder head crack may frequently be too small to be seen with the naked eye. But it may still be a serious issue.

Cracks are discovered through the use of dyes or pressure tests by some mechanics. Cylinder head testing is best carried out by a qualified auto technician, just like coolant checks.

Blown Head Gasket: Prevention Tips

It may be impossible to try to stop every probable head gasket failure occurrence. Thankfully, there are a few more prevalent common causes of head gasket failures that you, as a car owner, may have greater control over. You can avoid a head gasket failure and an expensive repair by being aware of these engine operating conditions.

To help prevent gasket failure, you can take the following preventative measures-

- When the engine starts to overheat, identify the issue as quickly as you can, then take the necessary steps to fix it.

- Check the coolant and engine oil levels frequently by opening the hood. If coolant or oil levels are often dropping, find the leak’s origin and make the necessary repairs.

- Replace coolant and engine oil as directed by the automobile manufacturer while performing maintenance on your vehicle. Consult the owner’s manual or repair manual of your car.

- Use only the antifreeze and engine oil that the manufacturer of your vehicle has advised.

- As soon as you observe a preignition or detonation state, identify the root of the issue and take immediate action to fix it.

Some car manufacturers have a reputation for creating vehicles with head gaskets that are prone to blow easily. In certain instances, head gasket issues have led car owners to petition the responsible automakers, demanding a recall. Despite this, head gasket issues can still be fixed and avoided without breaking the bank on upgrades and maintenance.

Blown Head Gasket Cost

Unfortunately, one of the most expensive auto repairs is replacing a head gasket. Not the head gasket itself, but rather where it is located in the engine compartment, is to blame for this. It is necessary to disassemble the engine because of its central location. This may take several hours, which increases how labor-intensive the repair is.

A novice or ordinary mechanic would not be suitable for the job. Therefore, if you think your automobile may have a burst head gasket, we advise taking it to a skilled and experienced mechanic.

Depending on the automobile model, a replacement head gasket will often cost you $100 to $200. The cost of labor is by far the biggest expense, as was already established. Depending on the automobile model and other variables, this labor cost will vary greatly. You should budget between $900 to $1500 for labor charges as a general rule.

While some strongly advise against using head gasket sealers, certain people swear by them. In actuality, there isn’t a single solution. It may occasionally function, but a complete repair is normally required.

Blown Head Gasket: Conclusion

The head gasket’s job is to keep the engine block and cylinder heads’ internal fluids from mixing with one another. These fluids typically include coolant, oil, and air/fuel mixture from the combustion chamber.

The term “blown head gasket” refers to a head gasket leak. Engine overheating is the most frequent cause of a burst head gasket. As a result, it’s critical to constantly check that the coolant level is appropriate.

Repairing a blown head gasket is more expensive than using a head gasket sealer. However, this is never a long-term fix, and it frequently doesn’t work at all. Due to the significant labor expenses involved, replacing a head gasket is one of the most expensive auto repairs.

A head gasket replacement will typically cost between $100 and $200. The labor cost, however, could be ten times higher, if not even more. Typically, you can anticipate spending $900 to $1500 on labor expenditures alone. Additionally, bear in mind that other parts may sustain damage as a result of a burst head gasket. The cost of the total repairs could so become significantly greater.

FAQs On Blown Head Gasket

What Is A Blown Head Gasket

A blown head gasket is when the seal between the cylinder head and engine block fails. Between these two areas of the engine, the head gasket seals the coolant route, the oil return passages, the cylinders, and the pistons.

How Much To Fix A Blown Head Gasket

Repairing a head gasket can cost more than a thousand dollars. The parts as well as labor are pricey and hence head gasket repairs typically cost between $9,00 and $1,500 on average.

How To Tell If Head Gasket Is Blown

It is simple to determine whether the head gasket on your engine has blown. Just look underneath the oil-filling cap. The inside of the oil cap will be mostly dry if the gasket is undamaged. You most likely have a gasket leak if you find a milky, brownish-yellow material that has about the thickness of a milkshake.

What Does A Blown Head Gasket Sound Like

If a head gasket fails and pressurized air or fuel leaks out, the cylinder’s compression is decreased. This decrease in compression causes the engine to function poorly and significantly reduces engine output. Typically, this kind of failure is followed by a knocking sound.

How To Start A Car With A Blown Head Gasket

It is possible to start a car with a blown head gasket if you make a few easy adjustments. First, you must constantly top off the engine coolant to keep your engine cool. Also, a temporary sealant can assist stop the crack from becoming worse if your head gasket hasn’t entirely burst.