Here’s what you need to know about the crank shaft position sensor…

- What Is A Crank Shaft Position Sensor?

- Symptoms Of A Faulty Crank Shaft Position Sensor

- Replacing Your Crank Shaft Position Sensor

- Diagnose A Faulty Crank Shaft Position Sensor

- Cost of Replacing Your Crank Shaft Sensor

- Maintaining Your Crank Shaft Position Sensor

- Different Types of Crank Shaft Position Sensors

- Problems With The Crank Shaft Position Sensor

- How To Install A New Or Replacement Sensor

- Aftermarket vs OEM Part For The Replacement

What is a Crank Shaft Position Sensor and How Does it Work?

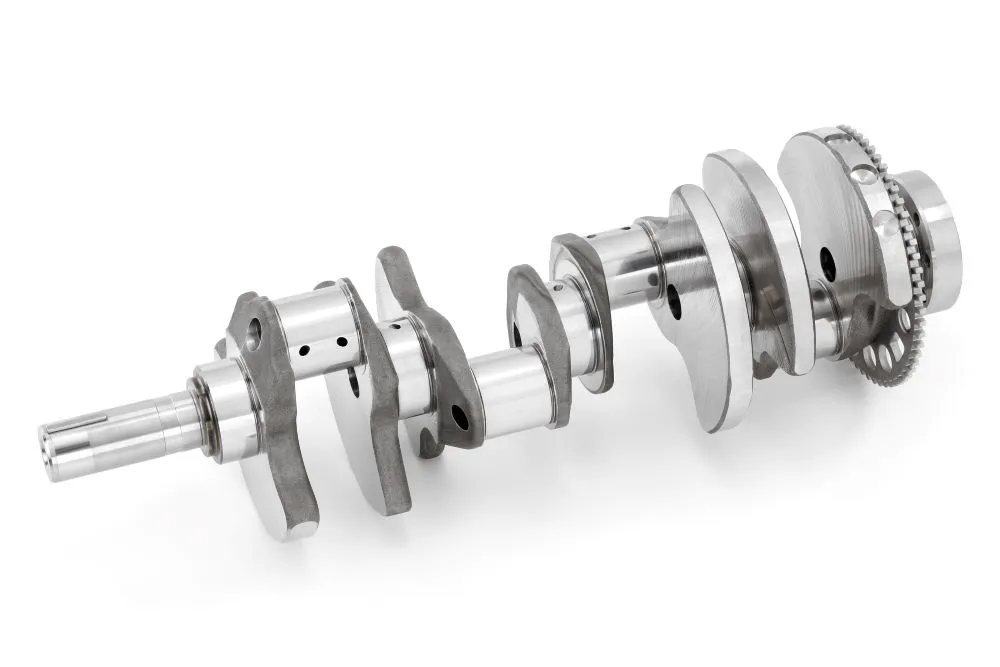

A Crankshaft Position Sensor (CPS) is a device used to monitor the position and rotational speed of the crankshaft in an internal combustion engine. It is typically located near the crankshaft, either at the front or rear of the engine.

The CPS works by sending an electrical signal to a computer when it detects changes in the rotational speed or position of the crankshaft. This signal is then used by the computer to adjust fuel delivery, ignition timing, and other parameters for optimal performance.

The CPS consists of two main components: a magnetic pickup coil and a Hall effect sensor. The magnetic pickup coil generates an alternating current (AC) signal as it passes over magnets embedded in the crankshaft pulley or flywheel. This AC signal is then sent to a Hall effect sensor which converts it into a digital pulse that can be read by an onboard computer system.

The frequency of this pulse indicates how fast or slow the crankshaft is rotating, while its amplitude indicates its position relative to the top dead center (TDC). By monitoring these signals, modern engines can adjust their performance accordingly for maximum efficiency and power output.

Common Symptoms of a Faulty Crank Shaft Position Sensor

A faulty crankshaft position sensor can cause a variety of symptoms in a vehicle. These symptoms may include difficulty starting the engine, stalling or misfiring during acceleration, reduced fuel efficiency, and illumination of the check engine light. In some cases, the vehicle may not start at all.

Additionally, among the other symptoms of a bad crankshaft position sensor; drivers may experience jerking or lurching when shifting gears as well as rough idling and decreased power while driving. If any of these symptoms are present in a vehicle it is important to have it inspected by a qualified mechanic to determine if the crankshaft position sensor is malfunctioning.

The Benefits of Replacing Your Crank Shaft Position Sensor

The crankshaft position sensor is an important component of any vehicle’s engine. It is responsible for monitoring the rotational speed and position of the crankshaft, which in turn helps to regulate the timing and firing of the spark plugs.

When this sensor fails, it can cause a variety of problems with your vehicle’s performance, including poor fuel economy, rough idling, stalling, and misfiring. Replacing your crankshaft position sensor can help to restore your vehicle’s performance and improve its overall efficiency.

- One benefit of replacing your crankshaft position sensor is improved fuel economy. When this component fails or wears out over time, it can cause a decrease in fuel efficiency due to incorrect timing or misfiring spark plugs. By replacing this part with a new one, you will be able to ensure that your engine is running at optimal levels for maximum fuel efficiency.

- Another benefit of replacing your crankshaft position sensor is improved engine performance. This component helps to regulate the timing and firing of spark plugs which are essential for proper combustion within an engine cylinder. If these components are not working correctly due to a faulty or worn-out crankshaft position sensor then it can lead to poor acceleration as well as reduced power output from the engine itself. Replacing this part will help restore proper combustion within each cylinder resulting in better acceleration and more power from your vehicle’s engine overall.

- Finally, replacing your crankshaft position sensor can also help reduce emissions from your vehicle’s exhaust system by ensuring that all cylinders are firing correctly at their optimal levels during operation. This will result in fewer pollutants being released into the atmosphere which benefits both you and our environment alike.

In conclusion, there are many benefits associated with replacing a faulty or worn-out crankshaft position sensor on any type of vehicle including improved fuel economy, better performance, and reduced emissions from its exhaust system. Taking care of this important maintenance task now will save you money down the road while also helping protect our environment at the same time.

How to Diagnose a Faulty Crank Shaft Position Sensor

A Crank Shaft Position Sensor (CKP) is an important component of a vehicle’s engine management system. It is responsible for monitoring the position and speed of the crankshaft, which in turn helps to control fuel injection, ignition timing, and other engine functions.

A faulty CKP can cause a variety of problems with your vehicle’s performance, including poor acceleration, stalling, or misfiring. Diagnosing a faulty CKP requires some knowledge of automotive systems and tools.

- The first step in diagnosing a faulty CKP is to check for any diagnostic trouble codes (DTCs). These codes are stored in the vehicle’s computer when it detects an issue with the sensor or its related components. To access these codes you will need to use an OBD-II scanner tool that can be purchased from most auto parts stores.

- Once you have retrieved any DTCs related to the CKP sensor (such as the P0336 code or the P0335 diagnostic error code), you can then begin troubleshooting further by checking for any loose connections or wiring issues that may be causing the problem.

- Next, you should inspect the sensor itself for signs of damage such as corrosion or physical damage due to wear and tear over time. If there are no visible signs of damage then it may be necessary to test its electrical output using a multimeter set on DC voltage mode.

- The expected reading should be between 0-5 volts depending on your specific make and model; if it reads outside this range then it could indicate that there is an issue with either the wiring or internal components within the sensor itself which would require replacement to restore proper operation.

- Finally, if all else fails then it may be necessary to replace your CKP entirely as this will ensure that all components are functioning correctly again without having to worry about further issues down the line due to worn-out parts or damaged wiring connections, and so on.

- Replacing your CKP requires some mechanical knowledge so if you do not feel comfortable doing this yourself then seek professional help from a qualified mechanic who has experience working on similar vehicles before attempting anything yourself.

The Cost of Replacing Your Crank Shaft Position Sensor

The cost of replacing a crankshaft position sensor can vary depending on the make and model of your vehicle. Generally, the cost for parts and labor to replace a crankshaft position sensor can range from $150 to $400.

The cost of the part itself will depend on the type of vehicle you have. For example, a crankshaft position sensor for a Honda Accord may be more expensive than one for a Ford Focus. Additionally, some vehicles may require additional parts or labor to complete the replacement process.

Labor costs will also vary depending on where you take your car for service and how experienced the technician is with this particular crankshaft repairs job. It is important to shop around and compare prices before making any decisions about where to take your car for service.

In addition to these costs, it is important to consider any other potential expenses that may arise during this repair process such as diagnostic fees or taxes that may be applicable in your area. It is always best practice to ask questions about all potential costs before agreeing to any repairs so that you are aware of what you are paying for ahead of time.

Tips for Maintaining Your Vehicle’s Crank Shaft Position Sensor

1. Check the Crank Shaft Position Sensor Regularly: It is important to check the crankshaft position sensor regularly for any signs of wear or damage. This can be done by visually inspecting the sensor and its wiring for any signs of corrosion, fraying, or other damage. If any issues are found, it is best to replace the sensor as soon as possible.

2. Keep the Sensor Clean: Dirt and debris can accumulate on the crankshaft position sensor over time, which can cause it to malfunction or fail prematurely. To prevent this from happening, make sure to keep the area around the sensor clean and free of dirt and debris.

3. Avoid Excessive Vibration: The crankshaft position sensor is sensitive to vibration, so it is important to avoid excessive vibration when driving your vehicle or when working on it to prevent damage or failure of this component.

4. Use Quality Parts When Replacing: If you need to replace your crankshaft position sensor, make sure that you use quality parts that are designed specifically for your vehicle’s make and model to ensure proper fitment and performance from your new part.

5. Follow Manufacturer’s Recommendations: Always follow the manufacturer’s recommendations when replacing a crankshaft position sensor to ensure optimal performance from your vehicle’s engine system.

Different Types of Crank Shaft Position Sensors and Their Uses

A Crank Shaft Position Sensor (CKP) is a device used to measure the position of the crankshaft in an internal combustion engine. It is typically used to detect misfires, monitor engine speed, and regulate fuel injection timing. The CKP sensor can also be used to detect other problems such as worn or damaged components in the engine.

- There are several types of crankshaft position sensors available on the market today. The most common type is a Hall Effect Sensor, which uses a magnetic field to measure crankshaft position. This type of sensor is reliable and accurate but can be expensive due to its complexity.

- Another type of CKP sensor is an Inductive Sensor, which uses an inductive coil to measure crankshaft position. This type of sensor is less expensive than a Hall Effect Sensor but may not be as accurate or reliable in some applications.

- The third type of crankshaft position sensor available on the market today is a Variable Reluctance Sensor (VRS). This type of sensor uses two coils that are placed around the crankshaft and then connected with wires that run through them both. As the crankshaft rotates, it creates changes in voltage between these two coils which can then be measured by an electronic control unit (ECU). VRS sensors are relatively inexpensive compared to other types but may not provide as much accuracy or reliability as other types do in certain applications.

- Finally, there are Optical Sensors available for use with crankshafts that use light beams instead of magnetic fields or inductive coils for measuring crankshaft positions accurately and reliably over long periods without any maintenance required from time to time like other types do require occasionally for optimal performance levels over extended periods without any issues arising from their usage at all times whatsoever.

Overall, each type of crankshaft position sensor has its advantages and disadvantages depending on what application they will be used for and how much accuracy/reliability/maintenance requirements one needs from them at all times. Therefore one needs to consider all factors before making their decision when selecting which one would best suit their needs accordingly.

Troubleshooting Common Problems with the Crank Shaft Position Sensor

The crankshaft position sensor is an important component of any vehicle’s engine. It is responsible for providing the engine control unit with information about the position and speed of the crankshaft.

If this sensor fails, it can cause a variety of problems, including poor fuel economy, rough idle, stalling, and even complete engine failure. Fortunately, some common troubleshooting steps can be taken to diagnose and repair issues related to this sensor.

- One of the most common problems associated with a faulty crankshaft position sensor is an intermittent loss of power or stalling while driving. This issue can be caused by several factors such as a loose connection or damaged wiring harnesses leading to the sensor itself. To diagnose this problem, it is important to check all connections leading to the crankshaft position sensor for any signs of corrosion or damage. If any are found they should be replaced immediately before further testing takes place.

- Another common issue related to this component is poor fuel economy due to incorrect readings from the crankshaft position sensor causing incorrect air/fuel mixture ratios in your vehicle’s combustion chamber. To diagnose this problem you should first check all wiring harnesses leading from your ECU (engine control unit) to ensure they are properly connected and free from damage or corrosion before proceeding with further testing on your vehicle’s fuel system components such as injectors and spark plugs etc..

- Finally, if you experience rough idling or misfiring when starting up your vehicle then it could indicate that there may be an issue with either your spark plugs or ignition coils which could also be caused by incorrect readings from your crankshaft position sensor due to its malfunctioning nature. To diagnose these issues you should first inspect all spark plugs for signs of wear and tear before replacing them if necessary followed by checking all ignition coils for proper operation using an ohmmeter. Once these components have been checked then further tests on other parts such as fuel injectors may need to be performed to identify any underlying faults within them which could also contribute towards misfiring issues.

In conclusion, diagnosing problems associated with faulty crankshaft position sensors requires careful inspection, testing, and replacement where necessary to ensure that correct readings are being provided back into your vehicle’s ECU so that it can accurately adjust air/fuel mixtures accordingly.

How to Install a New or Replacement Crank Shaft Position Sensor

Installing a new or replacement crankshaft position sensor is an important part of maintaining the performance and reliability of your vehicle. This guide will provide step-by-step instructions on how to install a new or replacement crankshaft position sensor.

Before beginning, make sure you have all the necessary tools and parts for the job. You will need a socket wrench set, pliers, wire cutters, electrical tape, and the new or replacement crankshaft position sensor.

Step 1: Locate the old crankshaft position sensor. It is usually located near the engine block on most vehicles. If you are unsure where it is located, consult your vehicle’s manual for more information.

Step 2: Disconnect any wiring connected to the old crankshaft position sensor by using wire cutters to carefully remove them from their terminals. Once disconnected, use pliers to remove any bolts that may be holding it in place before removing it completely from its mounting bracket.

Step 3: Install your new or replacement crankshaft position sensor into its mounting bracket and secure it with bolts using a socket wrench set if necessary. Make sure that all connections are tight before moving on to Step 4 below.

Step 4: Reconnect any wiring that was removed in Step 2 above by carefully attaching them back onto their terminals with electrical tape if needed for extra security and insulation against moisture damage over time due to weather conditions such as rain or snowfall etc..

Step 5: Test out your newly installed crankshaft position sensor by starting up your engine and listening for any unusual noises coming from under the hood which could indicate an issue with installation such as loose connections etc. If everything sounds normal then you have successfully installed your new or replacement crankshaft position sensor.

The Advantages and Disadvantages of Using an Aftermarket vs OEM Part for the Replacement

When it comes to replacing a part in a vehicle, there are two main options: aftermarket parts and original equipment manufacturer (OEM) parts. Aftermarket parts are produced by third-party companies and are not made by the original manufacturer of the vehicle.

OEM parts, on the other hand, are made by the same company that manufactured the car or truck. Both types of parts have their advantages and disadvantages when it comes to replacing a part in your vehicle.

- One advantage of using an aftermarket part is that it tends to be less expensive than OEM parts. This can be beneficial for those who need to replace a part but don’t have much money to spend on it. Additionally, aftermarket parts often come with warranties which can provide peace of mind if something goes wrong with them down the line.

- On the other hand, one disadvantage of using an aftermarket part is that it may not fit as well as an OEM part due to differences in design or manufacturing processes between different companies. Additionally, some aftermarket parts may not last as long as OEM ones due to lower quality materials being used in their construction or because they were not designed specifically for your make and model of vehicle like an OEM part would be.

- In contrast, one advantage of using an OEM part is that you know it was designed specifically for your make and model so you can rest assured that it will fit properly and last longer than an aftermarket one might due to its higher-quality materials being used during its construction process. Additionally, many times these types of replacement components come with extended warranties from their manufacturers which can provide extra protection if something goes wrong down the line with them too.

- However, one disadvantage associated with using an OEM replacement component is that they tend to cost more than their aftermarket counterparts do mainly because they were designed specifically for your make and model rather than being mass-produced like most third-party components are today. This means you may end up spending more money upfront when purchasing this type of replacement component compared to what you would pay for its cheaper counterpart from another company instead.