Here’s what you need to know if you need to replace your wheel bearings…

- Signs of a Failing Wheel Bearing

- Diagnose a Faulty Wheel Bearing

- Benefits of Replacing Your Wheel Bearings

- Choose the Right Replacement Parts

- Cost of Replacing Your Wheel Bearings

- Installing New Wheel Bearings Yourself

- Common Causes of Premature Wear

- Sealed vs Non-Sealed Wheel Bearings

- Using Aftermarket vs OEM Replacement Parts

- How to Properly Maintain and Care

What Are the Signs of a Failing Wheel Bearing?

A failing wheel bearing can cause a variety of symptoms, including:

1. Unusual noises coming from the wheel area, such as grinding, squealing, or humming.

2. Vibrations felt in the steering wheel or through the floorboard when driving at certain speeds.

3. Uneven tire wear due to misalignment caused by a worn-out bearing.

4. Difficulty turning the steering wheel due to increased friction in the bearing assembly.

5. Loose feeling when turning corners due to excessive play in the bearing assembly components.

6. Excessive heat coming from one of the wheels due to friction caused by a failing bearing component or lack of lubrication in that area of the vehicle’s suspension system.

How to Diagnose a Faulty Wheel Bearing

Diagnosing a faulty wheel bearing can be a difficult task, as the symptoms of a bad bearing can often be confused with other issues. However, there are some tell-tale signs that you should look out for to help you determine if your wheel bearing needs repair or replacement.

- One of the most common symptoms of a faulty wheel bearing is an unusual wheel bearing noise coming from the wheels when driving. This noise may sound like grinding, humming, or growling and will usually become louder when turning corners or accelerating. If you notice this type of noise coming from your vehicle’s wheels, it could indicate that one or more bearings are worn and need to be replaced.

- Another symptom to look out for is excessive vibration coming from the wheels while driving at higher speeds. This could also indicate that one or more bearings have become worn and require attention. Additionally, if you feel any play in the steering wheel when turning corners then this could also point towards an issue with your wheel bearings as they provide support for the steering system and allow it to move freely without any resistance.

- Finally, if your vehicle pulls to one side while driving then this could also suggest that there is an issue with one or more of its wheel bearings as they help keep all four wheels aligned correctly on the road surface.

If any of these symptoms are present then it’s important to have them checked by a qualified mechanic who can diagnose whether there is indeed an issue with your vehicle’s wheel bearings and advise on what repairs may be necessary to rectify them safely and effectively. To find out more, check out our guide on how many wheel bearings does a car have.

The Benefits of Replacing Your Wheel Bearings

Replacing your wheel bearings is an important part of maintaining the safety and performance of your vehicle. Wheel bearings are essential components that help keep the wheels spinning smoothly and evenly, allowing for a comfortable ride. Replacing them regularly can help ensure that your car runs safely and efficiently.

Here are some of the benefits of replacing your wheel bearings:

1. Improved Safety: Worn or damaged wheel bearings can cause excessive vibration, which can lead to premature tire wear or even a loss of control while driving. Replacing them regularly will help ensure that you have a safe ride every time you get behind the wheel.

2. Increased Performance: Newer, higher-quality wheel bearings will provide better performance than older ones, as they are designed to reduce friction between the wheels and axles for smoother operation and improved handling characteristics. This means faster acceleration, better braking response, and improved cornering ability when driving at higher speeds.

3. Reduced Maintenance Costs: Regularly replacing worn or damaged wheel bearings will reduce maintenance costs in the long run by preventing more serious damage from occurring due to excessive wear on other parts such as tires or suspension components caused by faulty bearing operation over time.

4. Extended Tire Life: By reducing friction between the wheels and axles, new wheel bearings can extend tire life by helping prevent uneven tread wear caused by misalignment. This means fewer trips to buy new tires, saving money in both short-term maintenance costs as well as long-term replacement costs.

Overall, replacing your vehicle’s worn-out or damaged wheel bearings is an important part of keeping it running safely, efficiently, and economically. Not only does it improve safety on the road but also helps increase performance while reducing maintenance costs over time.

How to Choose the Right Replacement Wheel Bearings for Your Vehicle

When it comes to replacing wheel bearings on your vehicle, it is important to choose the right ones for your specific make and model. The wrong bearing can cause premature wear and tear, as well as potential safety issues. Here are some tips to help you select the right replacement wheel bearings for your vehicle:

1. Check Your Vehicle’s Specifications: Before purchasing any new wheel bearings, be sure to check your vehicle’s specifications to determine the correct size and type of bearing that is required. This information can usually be found in the owner’s manual or online.

2. Consider Quality: When selecting a replacement bearing, it is important to consider quality over cost savings. High-quality bearings will last longer and provide better performance than cheaper alternatives that may not meet OEM standards or fit properly on your vehicle.

3. Choose OEM Parts: If possible, try to purchase original equipment manufacturer (OEM) parts when replacing wheel bearings on your vehicle as they are designed specifically for that make and model of car or truck and will provide a perfect fit every time.

4. Ask an Expert: If you are unsure which type of bearing is best suited for your particular application, don’t hesitate to ask an expert at a local auto parts store or mechanic shop who can help you find the right part for your needs quickly and easily without any guesswork involved.

The Cost of Replacing Your Wheel Bearings

Wheel bearings are an essential part of a vehicle’s suspension system, allowing the wheels to rotate freely and smoothly. Over time, wheel bearings can become worn or damaged due to normal wear and tear, leading to increased noise and vibration when driving.

- Replacing your wheel bearings is an important maintenance task that should be done regularly to ensure the safety of your vehicle. The cost of replacing your wheel bearings will depend on several factors such as the type of vehicle you have, the number of wheel bearings that need replacing, and where you take it for service.

- So, how much is the wheel bearing replacement cost? On average, you can expect to pay anywhere from $150-$400 for a single wheel bearing replacement job. This price range includes labor costs as well as parts costs such as new bearing sets and seals.

- If multiple wheel bearings need replacing at once, then the cost will increase accordingly. Additionally, if you take your car to a dealership for service instead of an independent mechanic shop then you may end up paying more due to higher labor rates charged by dealerships.

It is important to note that while replacing your wheel bearings may seem like a good way to save money in theory; it is not recommended unless you have extensive experience with automotive repair work since incorrect installation can lead to serious damage or even accidents down the road if not done properly.

Therefore it is best left up to professionals who know what they are doing when it comes time for this type of repair job on your vehicle.

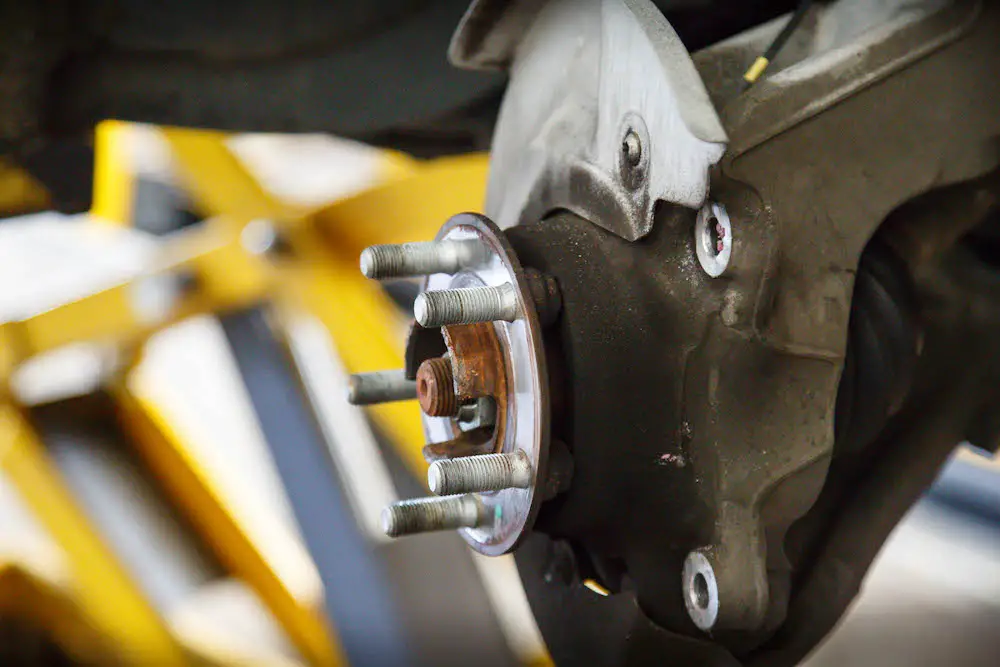

Tips for Installing New Wheel Bearings Yourself

Installing new wheel bearings is a relatively straightforward process, but it does require some specialized tools and knowledge. If you are considering doing the job yourself, here are some tips to help ensure a successful installation:

1. Make sure you have the right tools for the job. You will need a bearing press, bearing puller, torque wrench, and other specialty tools depending on your vehicle’s make and model.

2. Read through your vehicle’s service manual to familiarize yourself with the process before beginning work. This will help ensure that you don’t miss any important steps or overlook any potential problems during installation.

3. Clean all components thoroughly before beginning work to avoid contamination of the new bearings or other parts of the assembly during installation.

4. Use high-quality replacement parts whenever possible; this will help ensure that your wheel bearings last as long as possible without needing additional maintenance or repair in the future.

5. Follow all instructions carefully when installing new wheel bearings; if something doesn’t seem right or doesn’t fit properly, stop and double-check before continuing with installation to avoid damaging components or creating an unsafe situation for yourself and others on the road later on down the line.

Common Causes of Premature Wear on Wheel Bearings

Wheel bearings are an essential component of a vehicle’s suspension system, providing support for the wheels and allowing them to rotate freely. Unfortunately, wheel bearings can suffer from premature wear due to a variety of causes.

- One common cause of premature wear on wheel bearings is improper installation. If the bearing is not installed correctly, it may be subjected to excessive force or vibration which can cause it to wear out prematurely. Additionally, if the bearing is not properly lubricated during installation, this can also lead to accelerated wear and tear.

- Another potential cause of premature wheel bearing failure is contamination from dirt or water entering the bearing assembly. This contamination can damage the internal components of the bearing and reduce its lifespan significantly.

- In some cases, poor-quality parts may also contribute to premature wheel bearing failure. If a low-quality part was used in construction or repair work on a vehicle’s suspension system, this could lead to accelerated wear on its components over time due to inferior materials or manufacturing processes used in their production.

- Finally, driving habits may also play a role in causing premature wheel bearing failure; for example, if drivers frequently take sharp turns at high speeds they could put additional strain on their suspension system which could lead to accelerated wear on its components over time.

In conclusion, there are several potential causes of premature wear on wheel bearings including improper installation techniques; contamination from dirt or water; poor quality parts; and aggressive driving habits that put additional strain on suspension systems over time.

What You Need to Know About Sealed vs Non-Sealed Replacement Wheel Bearings

Wheel bearings are an essential component of any vehicle, providing support and stability to the wheels. When it comes to replacing wheel bearings, there are two main types: sealed and non-sealed. Understanding the differences between these two types is important for ensuring that your vehicle is safe and reliable.

- Sealed wheel bearings are pre-lubricated with grease and come with a rubber seal that prevents dirt, dust, water, or other contaminants from entering the bearing. This type of bearing requires no additional lubrication or maintenance after installation. Sealed wheel bearings provide superior protection against corrosion and wear compared to non-sealed wheel bearings.

- Non-sealed wheel bearings do not have a rubber seal around them like sealed ones do; instead, they rely on periodic lubrication to remain functional. Non-sealed wheel bearings require regular maintenance such as cleaning and re-greasing to prevent corrosion or wear over time. They also tend to be less expensive than sealed ones due to their simpler design.

When deciding which type of replacement bearing is best for your vehicle, consider both cost and convenience factors as well as how much protection you need from dirt, dust, water, or other contaminants that could damage your wheels over time if left unchecked.

- Sealed wheel bearings offer superior protection but may be more expensive than non-sealed ones; however, they require no additional maintenance after installation so may be more convenient in the long run if you don’t want to worry about regularly greasing them yourself or taking them into nearby wheel bearing repair shops near me for servicing every few months or so.

- Non-sealed wheel bearings can save you money upfront but will require regular maintenance for them to remain functional over time so make sure you factor this into your decision-making process when choosing which type of replacement bearing is best for your needs

The Pros and Cons of Using Aftermarket vs OEM Replacement Parts for Your Vehicle’s Wheels

When it comes to replacing the wheels on your vehicle, you have two main options: aftermarket and OEM (Original Equipment Manufacturer) replacement parts. Each option has its advantages and disadvantages, so it is important to consider both before making a decision.

- The primary advantage of using aftermarket parts is cost savings. Aftermarket wheels are typically much less expensive than OEM replacements, making them an attractive option for those on a budget.

- Additionally, aftermarket wheels often come in a variety of styles and sizes that may not be available from the original manufacturer. This can be beneficial if you are looking for something unique or custom-made for your vehicle.

- On the other hand, there are some drawbacks to using aftermarket parts as well. Quality control can be an issue with some manufacturers; while some offer high-quality products that meet or exceed OEM standards, others may produce inferior products that do not last as long or perform as well as their OEM counterparts.

- Additionally, since these parts are not made by the original manufacturer they may not fit properly or work correctly with other components in your vehicle’s system; this could lead to costly repairs down the road if problems arise due to improper installation or compatibility issues.

- OEM replacement parts offer several advantages over their aftermarket counterparts as well. Since they are made by the original manufacturer they will fit perfectly into your vehicle’s system and work correctly with all other components; this eliminates any potential compatibility issues that could arise from using an aftermarket part instead.

- Additionally, since these parts come directly from the factory they will usually have higher quality control standards than those found in third-party manufacturers; this means you can rest assured knowing that your new wheel will last longer and perform better than one produced by an outside source would have done so otherwise.

Ultimately when deciding between aftermarket vs OEM replacement wheels for your vehicle it is important to weigh both options carefully before making a decision. Consider factors such as cost savings, quality control, compatibility, and performance when choosing which type of wheel best suits your needs.

How to Properly Maintain and Care for Your New Replacement Wheel Bearings

Properly maintaining and caring for your new replacement wheel bearings is essential to ensure that they last as long as possible. Wheel bearings are an important part of your vehicle’s suspension system, and if they are not properly cared for, it can lead to premature wear and tear. Here are some tips on how to properly maintain and care for your new wheel bearings:

1. Check the bearing seals regularly. The seals on the wheel bearing should be checked at least once a year or more often if you drive in wet or muddy conditions. If the seals appear cracked or worn, replace them immediately to prevent dirt from entering the bearing assembly and causing damage.

2. Clean the wheel bearings regularly with a soft cloth dampened with mild soap and water solution. This will help remove any dirt or debris that may have accumulated over time, which can cause premature wear of the bearing components.

3. Lubricate the wheel bearings every 6 months or so using a high-quality lubricant specifically designed for use on wheel bearings such as grease or oil-based lubricants like lithium grease or synthetic oil-based lubricants like synthetic motor oil (5W30). Make sure you apply enough lubricant so that it covers all surfaces of the bearing assembly but not too much so that it runs out onto other parts of your vehicle’s suspension system when driving at speed over bumps in roads etc.

4. Inspect all components of your vehicle’s suspension system regularly including shocks, struts, springs, etc., as well as check tire pressure levels frequently to ensure proper alignment is maintained between all four wheels which will help reduce stress on your new replacement wheel bearings over time due to uneven weight distribution across each axle when driving at speed over bumps in roads, etc.

5. Have a professional mechanic inspect your vehicle’s suspension system annually including checking all components related to steering such as tie rods ends ball joints etc. (or other parts, such as the ball bearings on your car), this will help identify any potential problems before they become serious issues that could lead to costly repairs down the line if left unchecked for too long.

Following these simple steps will help ensure that you get the maximum life out of your new replacement wheel bearings while also helping keep you safe while driving by ensuring proper alignment between all four wheels is maintained at all times.