A starter replacement cost need not be unreasonable but may still set you back a few bucks.

In this article, I’ll be looking into the different ways in which you can get the starter replaced, along with the costs involved.

- What is a starter?

- Starter replacement cost

- How does a starter work?

- Starter rebuilding

- Faulty starter symptoms

- FAQs

Starter For Car

A starter motor is… well, it’s the motor used for starting a car.

The starter motor replaces the manual crank you may see on old vehicles such as the Ford Model T. There were also other ways of starting a car, such as dynamite!

Check out the detailed video below to see a Model T started with a hand crank. I highly recommend it.

If nothing else, this video should give you a grasp of how much work went into starting these cars. It wasn’t like today – just sit in the driver’s seat, turn the key, and away we go. Hand cranking was even quite dangerous.

Turning the handle “cranks” the engine – it makes it revolve. Hence, the pistons begin traveling up and down in the cylinders.

The aim of cranking the engine is to get enough compression in at least one cylinder for a successful ignition. When this cylinder ignites, it forces the piston down, giving power to the next cylinders in the 4-stroke cycle.

Once that’s done, the engine will begin running on its own power. You don’t need to crank it anymore. It’s vital to always crank with your left hand once the ignition is on – if you don’t, a backfire could easily break your wrist.

The starter motor replaces the hand crank. It’s powered by the car’s battery and uses a small pinion to engage with the flywheel on the end of the crankshaft. It’s much smaller than the flywheel but, due to the laws of gear ratios, is easily capable of rotating it.

How Much Is A Starter

To take your car to your local auto shop will likely cost between $250 and $400, depending on a few factors.

- Local area – the average labor rate varies dramatically from state to state and county to county. According to CarMD, Ohio averages the cheapest state for car repairs, followed by Maine, Michigan, Wisconsin, and Vermont. The most expensive states are the District of Columbia, Connecticut, California, Georgia, and New Jersey (in descending order).

- Your car’s make and model – the more common the car is, the cheaper the parts are likely to be. This is all related to supply and demand. The more of a particular car part you can find (in this case, the starter), the cheaper it’s likely to be.

The F-Series from Ford is still the best-selling set of cars in the US, with 787,422 sold in 2020. If you check around with a few parts websites and companies, you’ll see that the average price is $150 for a good-quality, new starter.

It’s a relatively simple job and shouldn’t take more than an hour, so labor costs will be pretty low – around $80, give or take.

These combine for a total of around $230 + taxes. You can learn more in our guide on the Honda Accord starter replacement cost.

You should note, however, that this is the most common vehicle in America. When it comes to other less frequently seen cars, you can only expect these numbers to go upward.

The other main advantage of getting professionals to do the work for you is that the work is insured. If anything goes wrong, they should cover it. Ensure you get some guarantee before any work is carried out, just to be on the safe side.

How Much To Replace A Starter

Replacing the starter by yourself should, clearly, cost less. This lesser cost is due to not paying labor charges. You’ll only have to pay out for the part.

In the example of the Ford F-150 used above, the starter motor costs $150 + taxes. You should, therefore, expect to pay about this much for it.

You can remove the old starter and replace it with the new one with basic tools. A 3/8″- or 1/4″-drive ratchet with extensions should do the trick. You might also need a torch or headtorch, and, very occasionally, you might need to raise the car off the ground. As such, you’ll need a jack and some axle stands or access to a hydraulic ramp or inspection pit.

How Does A Starter Work

Take a look at the animation shown below from TecknoMechanics on YouTube.

The starter motor shown in the above animation is a pre-engaged-type model, the most common one in modern cars. The other type of starter motor is an inertia-type, a trusted but older version.

It uses an electrical motor to spin the pinion that meshes with the flywheel. As this pinion turns, the flywheel turns, cranking the engine.

The power for this electric motor comes from the car’s battery. The circuit is basic in appearance but contains many complex parts.

The circuit is made up of the battery, the starter motor, and your ignition key. You’ll probably be familiar with the different marks by your key.

- OFF.

- ACC.

- ON.

- START.

When you turn your key to the “START” position, that’s what makes the “rrr – rrr – rrr” noise. When it’s at this point, the switch is closed, completing the circuit between the starter motor and the battery.

This enables current to flow from the battery to the solenoid on top of the motor. The solenoid is a type of electromagnet. When the battery energizes it, the plunger (as seen in the video) slides along. It connects two copper terminals, completing the circuit and causing the rotor within the starter to spin.

What Does A Starter Look Like

To increase the torque, planetary gears are included between the rotor and the pinion. These gears help the starter motor have that extra turning force, meaning that starting the engine is more effortless.

As the plunger moves towards the copper terminals, it also pushes the pinion out so that it’s level with the flywheel. When the power is disconnected from the solenoid (that is, you let go of the key), the plunger moves back to its rest position and pulls the pinion back from the flywheel. This prevents the flywheel from damaging the motor by spinning the pinion.

To prevent this from happening, starter motors include a one-way clutch before the pinion. This one-way clutch effectively disconnects the pinion from the rest of the starter motor and helps to prevent heavy damage.

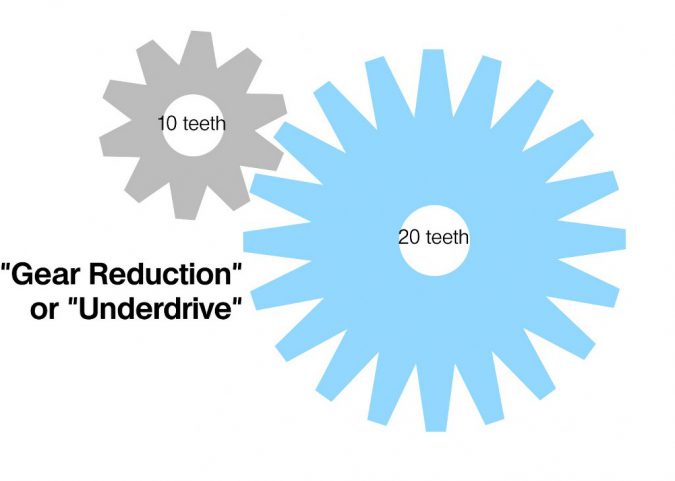

The gear ratio between the pinion and the flywheel is generally between 15:1 and 20:1. That is, the pinion will do 15 rotations at the same time it takes the flywheel to do 1.

In this illustrative example, the gray cog represents the pinion gear. The blue cog represents the flywheel. The pinion gear has just 10 teeth compared to the flywheels 20. This means it will spin twice at the same time the flywheel spins once. Although the flywheel won’t turn so quickly, there is a greater amount of torque – “turning force” – for the pinion to spin it. In reality, the gear ratios between the pinion and flywheel are between 15:1 and 20:1, as detailed above.

Rather than the battery directly, a solenoid is used to power the starter because it requires a much lower current level to operate. If the circuit bypassed the solenoid, the wires would need to be much thicker to handle the flow of electricity.

I highly recommend watching the video included above, which is incredibly helpful for visualizing the whole process.

Pre-Engaged Vs Inertia Starter

With a pre-engaged starter, the pinion juts out from the motor before it begins to spin. It accomplishes this through the use of the solenoid and plunger, as explained below. The pinion physically cannot revolve unless the solenoid has already pushed it out, level with the flywheel.

You might hear an inertia-type starter being referred to as a Bendix-type.

An inertia-type starter works using, surprisingly enough, inertia. The pinion gear is on the other side of the flywheel, and the pinion drive is on a screw gear. Because this screw gear can’t turn quite as quickly as the motor rotates, it “falls” back towards the flywheel, eventually making contact.

When the pinion gear hits the flywheel, it’s traveling with some force. In some ways, this is good, meaning that heavy flywheels can be rotated more easily. In some ways, though, it’s bad. Because the pinion hits the flywheel with such force, it causes damage to the teeth on both gears over time.

Over time, the industry moved towards pre-engaged starter motors to prevent this damage from happening.

Check out the video below to see it clearly explained. I highly recommend a watch. Moss Motors, Ltd. produced this video.

Bad Starter

Like all mechanical parts, a starter motor will wear out over time and need replacing. It’s an inevitable fact. When it needs replacing, you haven’t necessarily done anything wrong – it’s something you repeatedly use every time you start the car. Eventually, something is bound to go wrong down to general use and wear.

The starter motor could also be damaged in the following circumstances.

- Faulty wiring – if the current coming from the battery is excessive, it might damage the solenoid, meaning the rotor won’t spin properly, and the pinion won’t engage. The same situation would occur if there was insufficient current due to a fault in the wiring or battery cells. Short-circuits and other such conditions could also redirect the flow of electricity.

- Leaving the key engaged in the start position for too long – if you leave the key in this position for too long, the flywheel could start driving the motor instead of the other way around. The one-way clutch should negate most of this damage, but it isn’t always 100% effective. To prevent this from happening, you should always let go of the key the moment the engine roars into life.

- Incorrect installation – if the motor isn’t in the right place, it won’t mesh with the flywheel properly. It could damage the splines on either the pinion or flywheel itself.

- Individual components of the starter fail due to wear – the solenoid, motor itself, and pinion are all common failure points.

Health And Safety

If you decide to work on your starter, feel free – lots of people do.

Make sure, though, to work safely. Disconnect the battery long before you even think about working on the starter motor and make sure there’s no way for it to slip back into place, completing the circuit. Keep the keys out of the ignition and, for peace of mind, well away from the car. Finally, as I’ve experienced myself, make sure nobody comes along and tries to start the key while you’re working on wired-up electrical components.

Always work in a safe environment and wear latex or nitrile gloves to protect the skin on your hands.

Starter Rebuild

But, you might wonder about the differences between a starter rebuild and a complete replacement. It’s certainly possible to rebuild a starter motor instead of replacing it. However, to have any chance of successfully doing this, you’ll need to have a decent understanding of electrical diagnosis as well as the make-up of the device itself.

It doesn’t usually make sense to take your starter to a repair shop and ask them to replace it because it will usually cost more in labor charges than getting a replacement. The one exception to this rule is if you own a fleet of vehicles – for example, a delivery company or a range of taxis (or, you could learn how to drive for Uber). In this case, it often makes sense to hire a mechanic and pay them standard hourly rates rather than taking the cars to a garage every time.

If you hire your own mechanic, you could expect to pay $30 per hour. Labor rates in garages are more likely to be closer to $100 per hour – i.e., lots. As long as there’s enough work to keep the employee busy, you’re looking at savings of around 70%.

Of course, thinking about your personal car again, you could still try to fix your starter motor yourself. Taking it to a garage could still be an option, but you’ll probably end up paying more than you would for a replacement.

Rebuild Vs Replacement

Trying to repair and rebuild it yourself is another possibility. In effect, you’ll be paying for it with your time rather than your hard-earned cash.

To go about this, you’ll, of course, need to remove the starter motor, but before doing so, run a quick OBD scan. Occasionally, this scan might tell you the problem itself and save you many arduous hours of diagnosis.

Once you’ve got the starter removed, use a digital multimeter to find the fault. Nine times out of ten, it’ll be an electrical issue. There may also be physical signs of mechanical wear – check for cracks, cuts, grooves, etc.

Once you’ve found what needs replacing, fix it. Before reconnecting it to the car, use a power pack to check the starter works properly, being careful not to shock yourself.

When reconnecting to the car, one of the main things to watch out for is to make sure that all the connecting wires are correctly attached and in the right places. It’s very easy to install the correct wire in the wrong position, causing a short circuit. Make sure that doesn’t happen.

How To Know If Starter Is Bad

It can be hard to differentiate between problems with the battery and issues with the starter on the surface. Although the ignition switch connected to the key may occasionally break too, it’s far less common.

More often than not, it’s the battery at fault rather than the starter. To rule out the battery, you should get a battery tester. Once you’ve connected it up to the battery, it’ll give you a reading and an idea of the battery’s health, as well as whether or not it needs replacing.

Some advanced battery testers will also provide information on the alternator and starter motor. If you have one of these at your disposal, it’s undoubtedly worth checking these while you’re at it. There’s a high likelihood you’ll find fault with at least one of these components if your car isn’t starting correctly.

The video below from 1A Auto on YouTube shows a simple model.

You might notice some of the following:

- When you turn the key, nothing happens; no click, nothing.

- A small click but no other noise when you put the key in and turn it to START.

- You might hear a slower version of the “rrr – rrr – rrr” noise you usually get when the car is starting. The engine might still start but struggle to do so.

- A grinding, crunching noise once the engine has started.

In all of the above examples – shortly to be delved into in more detail below – I’ll assume that you’ve already ruled out the battery and the ignition switch as the cause and confirmed that the starter is the problem. I’ll also assume the use of a pre-engaged-type starter.

Starter Replacement Symptoms #1: No Noise At All

If nothing at all is happening and you’ve made sure that the battery is all fine (check your lights and radio etc., are working), it indicates something wrong with either the wiring heading into the starter or the solenoid.

Wires can work their way loose or become frayed due to one reason or another. Any problems here could disrupt the circuit, meaning the current doesn’t make its way to the starter. You could also have a short circuit, although this is more likely to develop at the time of installation rather than years into the part’s usage.

The lack of a “click” sound also indicates that the pinion isn’t pushing out to being level with the flywheel and, therefore, the plunger isn’t moving within the solenoid. Because the solenoid isn’t moving, it won’t complete the circuit with the rotor. Consequently, the pinion will neither spin nor move outward.

In this case, the problem could also lie with the solenoid. Problems with electromagnets can be fiddly as they are precisely engineered bits of kit. While it may be possible to fix the part manually, it might save you a lot of time to just replace the whole thing.

If you cant hear a noise reader our guide here.

Starter Replacement Symptoms #2: A Small Click Only

In this case, we’re talking about when you turn the key but only hear a slight tap or click with no “rrr – rrr – rrr” – it doesn’t crank or turn over.

A few things could cause the click but, in the context of starter motors, the most likely reason for this noise is the movement of the solenoid’s plunger and subsequently the pinion gear.

Although the pinion gear is pushing out to engage with the flywheel, it’s not turning. That’s why you don’t hear the usual start-up noises.

All of this is indicative of some kind of problem with either the solenoid or the motor itself.

If you hear the sound of the motor spinning – a kind of whirring sound somewhat similar to a blow dryer – but still nothing is happening, there may be a fault with the gearing system within the starter.

Again, if you know what you’re doing and have the necessary equipment, you may well be able to repair a starter displaying these symptoms. If in doubt, however, it’s usually the simplest and cheapest to replace it.

Starter Replacement Symptoms #3: Slower Cranking

In these cases, the starter motor’s pinion gear is engaging with the flywheel and successfully turning it… but without its usual amount of torque. Thus, we can deduce that the problem lies somewhere in the power supply of the starter.

Usually, this problem is caused by an insufficient voltage – that is, there isn’t enough electrical energy to power the starter. If the battery seems fine, the issue probably stems from a wiring connection or loom.

Failing that, the motor itself could have any number of internal causes for this situation.

Like the previous examples, you’ll need specialist skills and electrical equipment to find the problem. It would likely save considerable amounts of time to simply replace the starter.

Starter Replacement Symptoms #4: Grinding And Crunching

Suppose you hear a grinding- or crunching-type noise. In that case, this represents the pinion gear not engaging (or disengaging, depending on when you hear it) from the flywheel properly.

There may be damaged teeth on either the pinion gear or flywheel. The noise could also stem from a damaged linkage between the plunger and pinion.

If the noise happens consistently, it’ll be doing damage to both the starter and the flywheel. When replacing or repairing the starter, you should also check the flywheel for extensive damage. If it’s missing a large number of teeth, you may have to replace that too, or else the new starter will have nothing to link up with.

Unfortunately, because the flywheel is attached to the crankshaft and will require a considerable amount of disassembly work, the cost of getting a flywheel replacement is much more than a starter – somewhere between $500 and $1,000.

To avoid those extortionate sums, get your starter fixed or replaced the moment you begin hearing those grinding sounds.

Conclusion On Starter Replacement Cost

Overall, a starter replacement cost is likely to fall somewhere between $250 and $400 if you take the car to a shop. The numbers could go even higher for rarer vehicles with bigger engines (and consequently bigger flywheels).

For a DIY job, you’ll only have to pay out for the parts, assuming you already have all the necessary equipment. To buy the parts, you should budget about $200, again depending on various factors as discussed above.

Thanks for reading our guide on a starter replacement cost!

FAQs On Starter Replacement Cost

If you’re still curious to learn more about a starter replacement cost, our FAQs here might be of some help…

How Much Does A Starter Cost

A starter replacement cost will usually set you back somewhere around $250 to $400 for most cars, although this also accounts for the cost of labor to have someone install it for you. If you want to replace the starter yourself, you can find the starter itself selling for around $150 at the bottom end or up to $300. This will vary depending on the make and model of your vehicle. If the starter motor isn’t too badly damaged, you could instead opt for a rebuild instead of a total replacement. Rebuilding a starter involves taking it apart and replacing only the worn-out components. Then, re-using the ones that otherwise work just fine.

How To Know If Your Starter Is Bad

A clear tell-tale sign that your starter isn’t working right is when your car isn’t starting or has trouble cranking. Although, these symptoms can usually be mistaken for a bad battery or a faulty ignition. Otherwise, a malfunctioning starter does share similar cues, such as the car not cranking when you start the ignition. Moreover, you’d not hear any clicks (or sometimes very subtle clicks, but nothing else happens), which is indicative that the starter has gone awry. If not, your car might start after some difficulty, but the cranking is slower, and you might be able to hear a grinding or crunching sound.

Where Is The Starter On A Car

In most cars, you could find the starter located on the driver’s side of the engine. It’s immediately visible as a large metal cylinder, found jammed underneath or near the manifolds. To make finding it a bit easier, you can have someone sit in the driver’s seat, and try to turn the ignition on. You might be able to trace the clicking sounds a starter emits. Another visual clue that you’re looking at a starter is that it’s mounted onto the car with a set of bolts. Plus, there are often two wires leading into your car’s starter unit. Due to it being buried rather deep inside the engine compartment, it can be hard to find the starter at first.

How Long Do Starters Last

For the most part, starters are designed to last for a long time. On average, your typical starter motor could easily outlast 100,000 to 150,000 miles before it needs to be rebuilt or replaced. In most cars, the starter is made to last a lifetime. However, it could also fail prematurely, thus prompting you to seek a starter replacement cost, due to wear and tear. Seeing how often the starter is used – it’s activated anytime you’re turning your car on – the wear and tear is significant enough that it could wear down as time passes. Otherwise, bad wiring, leaving your keys in the START position for too long, or faulty components would also cause the starter to die prematurely.

How Long Does It Take To Replace A Starter

A starter replacement cost, unlike many other automotive repairs, is relatively cheap. This is partly due to how accessible starter motors generally are. In other words, it’s easy to find the starter, remove the old one, and bolt the replacement unit back in. As long as mechanics don’t have to spend too much time on your car, it’ll save you a lot down the line in labor costs. Most experienced mechanics could handily replace the starter in around or under 1 hour. If your car’s hiding the starter motor a bit too well, or if you aim to do this yourself, it may take you between 2 to 4 hours to replace it, instead.