- How Does a Catalytic Converter Work

- Benefits of Installing a Catalytic Converter

- Common Problems with Catalytic Converters

- Diagnose a Faulty Catalytic Converter

- Different Types of Catalytic Converters

- Chemistry Behind the Catalytic Conversion

- Environmental Benefits of a Catalytic Converter

- Properly Maintain Your Catalytic Converter

- Exploring the Impact of Aftermarket Parts

- OEM vs Aftermarket Replacement Parts

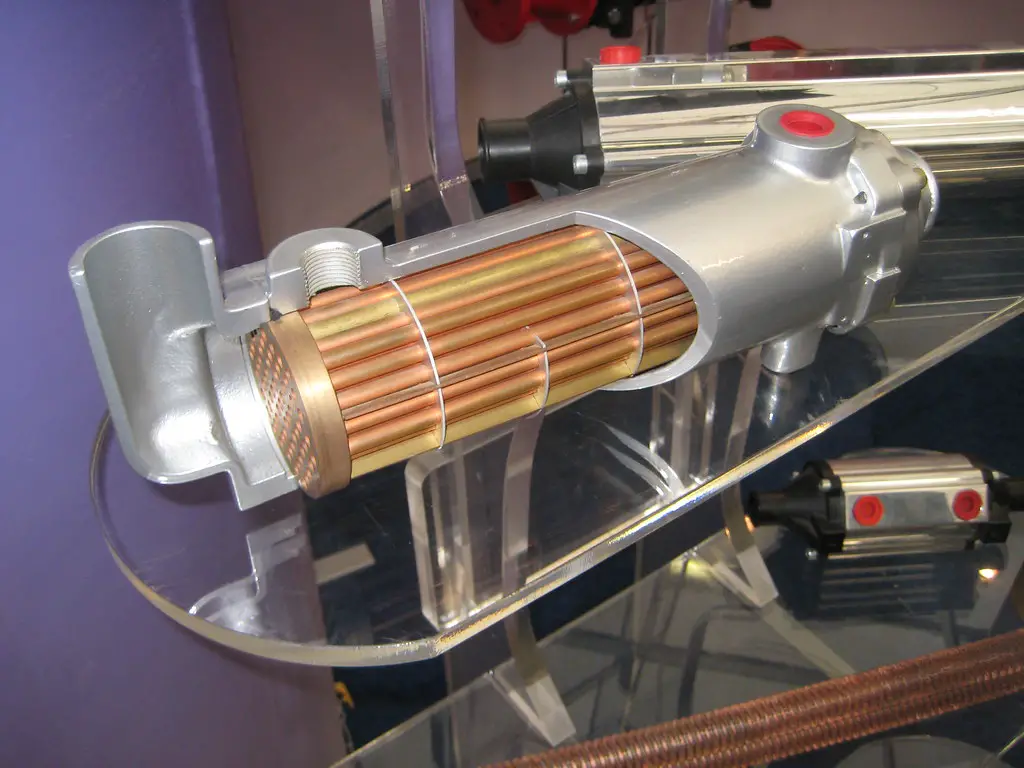

What Is a Catalytic Converter and How Does It Work?

A catalytic converter is an emissions control device that is fitted to the exhaust system of a vehicle. It works by converting harmful pollutants in the exhaust gases into less harmful substances before they are released into the atmosphere.

The catalytic converter does this by using a catalyst, usually platinum or palladium, to chemically convert pollutants such as carbon monoxide and hydrocarbons into carbon dioxide and water vapor. The catalytic converter works by passing the exhaust gases through a honeycomb-like structure coated with precious metals such as platinum or palladium.

As the exhaust passes through this structure, it comes into contact with these metals which act as a catalyst for chemical reactions that break down pollutants in the gas. This process reduces emissions of harmful substances such as carbon monoxide and hydrocarbons which can cause air pollution and health problems if released directly into the atmosphere.

Catalytic converters are an important part of modern vehicle emission control systems and have been mandatory on all new cars since 1975 to reduce air pollution from vehicles. They are also used on other types of engines such as those found in boats, motorcycles, lawnmowers, generators, etc., where they help reduce emissions from these sources too.

The Benefits of Installing a Catalytic Converter

The catalytic converter is an important component of a vehicle’s exhaust system. It helps to reduce the number of harmful pollutants released into the atmosphere by converting them into less harmful substances. Installing a catalytic converter can provide numerous benefits, both for the environment and for your vehicle.

- One of the primary benefits of installing a catalytic converter is that it helps to reduce air pollution. The device works by converting toxic gases such as carbon monoxide and hydrocarbons into less harmful substances like nitrogen and water vapor. This reduces the amount of these pollutants released into the atmosphere, helping to improve air quality in your area.

- Another benefit of installing a catalytic converter is that it can help improve fuel efficiency in your vehicle. The device works by reducing emissions from your engine, which allows it to run more efficiently and use less fuel in the process. This can result in significant savings on fuel costs over time, making it an economical choice for many drivers.

- Finally, installing a catalytic converter can also help extend the life of your vehicle’s engine components by reducing wear and tear caused by excessive emissions from its exhaust system. By reducing these emissions, you can help ensure that all parts are functioning properly and last longer than they would otherwise without this device installed on your car or truck’s exhaust system.

Overall, there are numerous benefits associated with installing a catalytic converter on your vehicle’s exhaust system including improved air quality, increased fuel efficiency, and extended engine life expectancy due to reduced wear-and-tear caused by excessive emissions from its exhaust system components.

Therefore, if you are looking for ways to make sure that you get the maximum performance out of your car or truck while also helping protect our environment, then investing in this type of device may be worth considering.

Common Problems with Catalytic Converters

The catalytic converter is an important part of a vehicle’s exhaust system, as it helps to reduce the number of harmful emissions released into the atmosphere. Unfortunately, these components can be prone to problems and failure. Common issues with catalytic converters include clogging, overheating, and damage due to fuel contamination.

- Clogging is one of the most common problems associated with catalytic converters. This occurs when particles such as soot or ash build up inside the converter and block its flow. This can cause a decrease in engine performance and an increase in emissions levels. To prevent this from happening, it is important to regularly maintain your vehicle’s exhaust system by replacing air filters and spark plugs on a regular basis. So, be wary of the symptoms of a clogged catalytic converter, as well as figure out whether can a bad catalytic converter cause a misfire.

- Overheating is another issue that can affect catalytic converters. When the component gets too hot due to excessive use or lack of maintenance, it can cause damage to its internal components which will lead to decreased performance or even complete failure of the unit. To avoid this problem, make sure you are not overworking your engine by driving at high speeds for extended periods of time or carrying heavy loads in your vehicle for long distances without taking breaks in between trips. Additionally, ensure that you are regularly checking your oil levels and replacing any worn-out parts as needed so that your engine does not become too hot while running. You can confirm this with a catalytic converter temperature test.

- Finally, fuel contamination can also be a problem for catalytic converters if there are impurities present in the gasoline being used by your vehicle’s engine such as dirt or water droplets which could potentially damage its internal components leading to decreased performance or complete failure of the unit altogether. To prevent this from happening make sure you only use clean gasoline when filling up your tank and check for any signs of contamination before doing so if possible (elevated levels of sediment). Additionally, have any necessary repairs done immediately if you notice any changes in how well your car runs after refueling it with contaminated gasoline so that further damage does not occur over time due to prolonged exposure.

How to Diagnose a Faulty Catalytic Converter

Diagnosing a faulty catalytic converter can be a difficult task, as the symptoms of a failing converter can be similar to those of other engine problems. However, there are certain signs that may indicate that the catalytic converter is not functioning properly (and note the signs of a bad catalytic converter).

- The first sign of a faulty catalytic converter is an illuminated check engine light on the dashboard. This indicates that there is an issue with one or more components in the vehicle’s exhaust system, and it could be caused by a malfunctioning catalytic converter.

- Another symptom of a failing catalytic converter is reduced fuel efficiency and power output from the engine. This occurs because when the catalyst inside the unit becomes clogged or damaged, it restricts exhaust flow and reduces performance.

- In some cases, you may also notice an unusual smell coming from your vehicle’s exhaust system when accelerating or idling at low speeds. This smell could indicate that your catalytic converter has overheated due to excessive backpressure in the exhaust system caused by clogging or damage to its internal components.

- Finally, if you hear rattling noises coming from underneath your car while driving at low speeds, this could also indicate that your catalytic converter needs to be replaced as it may have become loose due to damage or corrosion over time.

If any of these symptoms are present in your vehicle then it is recommended that you take it for professional diagnosis and repair as soon as possible to avoid further damage being done to other parts of your car’s exhaust system such as oxygen sensors and mufflers which can lead to costly repairs down the line if left unchecked for too long.

The Different Types of Catalytic Converters Available

Catalytic converters are an important part of a vehicle’s exhaust system. They help reduce the number of harmful pollutants released into the atmosphere by converting them into less harmful substances. There are several different types of catalytic converters available, each designed to meet specific needs and requirements.

- The most common type is the three-way catalytic converter, which is used in most gasoline-powered vehicles. This type of converter uses a combination of platinum, palladium, and rhodium to convert carbon monoxide (CO) into carbon dioxide (CO2), hydrocarbons (HC) into water vapor (H2O), and nitrogen oxides (NOx) into nitrogen gas (N2).

- Another type is the diesel oxidation catalyst, which is used in diesel engines. This converter uses a combination of platinum and palladium to convert CO and HC into CO2 and H2O respectively. It also helps reduce NOx emissions by oxidizing them with oxygen from the air intake system.

- The selective catalytic reduction (SCR) converter is another option for diesel engines that helps reduce NOx emissions even further by injecting urea or ammonia solution directly into the exhaust stream before it enters the SCR catalyst chamber where it reacts with NOx molecules to form harmless nitrogen gas and water vapor.

- Finally, there are also hybrid catalytic converters available that combine two or more technologies such as three-way catalysis with SCR technology for maximum efficiency in reducing emissions from both gasoline-powered vehicles as well as diesel engines.

Overall, there are many different types of catalytic converters available in today’s market depending on your vehicle’s needs and requirements for reducing emissions levels while still providing optimal performance levels at all times.

Understanding the Chemistry Behind the Catalytic Conversion Process

The catalytic conversion process is a chemical reaction that involves the use of a catalyst to speed up the rate of reaction. A catalyst is a substance that increases the rate of a chemical reaction without being consumed in the process. Catalysts are used in many industrial processes, such as petroleum refining and petrochemical production, to increase efficiency and reduce costs.

For catalytic conversion to take place, two reactants must be present: an oxidant and a reductant. The oxidant is typically an oxygen-containing compound such as oxygen gas or hydrogen peroxide, while the reductant can be any number of compounds including hydrocarbons or alcohols.

During this process, electrons are transferred from one molecule to another to form new products. This transfer occurs at much faster rates than would occur naturally due to the presence of the catalyst which helps facilitate electron transfer between molecules more quickly than it would occur without it.

The mechanism behind catalytic conversion involves several steps: firstly, adsorption occurs when molecules attach themselves to active sites on the surface of the catalyst; secondly, activation takes place when energy is added into these molecules so they can break apart; thirdly, oxidation-reduction reactions occur where electrons are transferred between molecules; fourthly desorption happens when newly formed products detach from active sites on the surface of catalyst; finally regeneration occurs when energy is removed from the system allowing for new reactants to attach onto active sites on the surface again starting the cycle over again.

Catalytic converters have been used for decades in automobiles as part of their exhaust systems to reduce emissions by converting harmful pollutants into less toxic substances before they enter the atmosphere. This technology has been instrumental in reducing air pollution levels around the world making it safer for us all to breathe cleaner air every day.

What Are the Environmental Benefits of Using a Catalytic Converter?

“Catalytic Converter” by Hiddenpower is licensed under CC BY-NC-SA 2.0

A catalytic converter is an important component of a vehicle’s exhaust system, designed to reduce the number of harmful pollutants released into the atmosphere. By converting toxic gases such as carbon monoxide and hydrocarbons into less harmful substances, catalytic converters play a vital role in reducing air pollution.

The environmental benefits of using a catalytic converter are numerous. Firstly, they help to reduce emissions of nitrogen oxides (NOx), which are known to cause smog and acid rain. They also help to reduce emissions of volatile organic compounds (VOCs), which can contribute to ground-level ozone formation and have been linked with respiratory illnesses such as asthma.

Additionally, they can reduce the amount of carbon monoxide released into the atmosphere by up to 95%, helping to improve air quality and protect public health. In addition, catalytic converters can also help improve fuel efficiency by reducing engine drag caused by unburned fuel particles in the exhaust stream.

This helps vehicles run more efficiently while consuming less fuel, resulting in fewer greenhouse gas emissions being released into the atmosphere. Overall, it is clear that using a catalytic converter has many environmental benefits that should not be overlooked when considering vehicle maintenance or purchasing decisions.

By helping to reduce air pollution levels and improve fuel efficiency, these devices play an important role in protecting our environment for future generations.

How to Properly Maintain Your Vehicle’s Catalytic Converter

Maintaining your vehicle’s catalytic converter is essential for keeping your car running smoothly and efficiently. The catalytic converter is an important part of the exhaust system, as it helps to reduce harmful emissions from the engine. Here are some tips on how to properly maintain your vehicle’s catalytic converter:

1. Check Your Vehicle’s Maintenance Schedule: Make sure you follow the manufacturer’s recommended maintenance schedule for your vehicle, as this will help ensure that all components of the exhaust system are functioning properly. This includes checking and replacing spark plugs, air filters, and other parts that may affect the performance of the catalytic converter.

2. Use High-Quality Fuel: Using high-quality fuel can help keep your engine running cleanly and efficiently, which in turn can help extend the life expectancy of your catalytic converter. Avoid using low-grade or contaminated fuel whenever possible to prevent damage to this important component of your car’s exhaust system.

3. Monitor Your Vehicle’s Emissions: Regularly monitoring emissions levels from your vehicle can help you identify any potential problems with its performance before they become serious issues that require costly repairs or replacements. If you notice a significant increase in emissions levels from normal levels, it could be a sign that there is an issue with either the fuel or ignition systems which could be causing damage to the catalytic converter over time if not addressed promptly by a qualified mechanic or technician.

4. Have Your Catalytic Converter Inspected Regularly: It is important to have a professional inspect and service your vehicle’s catalytic converter at least once every two years (or more frequently if recommended by the manufacturer). This will ensure that any potential problems are identified early on so they can be addressed before they cause further damage or require expensive repairs down the line.

Following these simple steps will help keep your car running smoothly while also helping protect its valuable components like its catalytic converters from unnecessary wear and tear over time.

Exploring the Impact of Aftermarket Parts on Your Vehicle’s Performance and Emissions Control System

The use of aftermarket parts in vehicles has become increasingly popular in recent years. While these parts can provide a number of benefits, such as improved performance and enhanced aesthetics, they can also have an impact on your vehicle’s performance and emissions control system.

It is important to understand the potential effects that aftermarket parts may have on your vehicle before making any modifications. When it comes to performance, aftermarket parts can often improve the power output of a vehicle by increasing its horsepower or torque.

This can be beneficial for those looking to get more out of their car or truck, but it is important to note that this increase in power may come at the expense of fuel economy. Additionally, some aftermarket components may not be compatible with existing systems and could cause damage if installed incorrectly.

In terms of emissions control systems, many aftermarket components are designed with less stringent standards than those used by original equipment manufacturers (OEM). This means that they may not meet the same level of efficiency as OEM components when it comes to reducing harmful pollutants from entering the atmosphere.

Furthermore, some aftermarket parts may even interfere with existing emissions control systems and lead to increased levels of pollution being released into the environment. It is important for drivers who are considering installing any type of aftermarket part on their vehicles to research both its potential benefits and drawbacks before making a purchase decision.

Doing so will help ensure that you make an informed decision about how best to modify your vehicle without compromising its safety or environmental impact.

Comparing OEM vs Aftermarket Replacement Parts for Your Vehicle’s Exhaust System

When it comes to replacing the exhaust system of your vehicle, you have two main options: OEM (Original Equipment Manufacturer) parts or aftermarket parts. Each option has its own advantages and disadvantages, so it is important to consider both before making a decision.

- OEM parts are designed and manufactured by the same company that made the original part for your vehicle. This means that they will fit perfectly and be of high quality, as they are made with the same materials and specifications as the original part. Additionally, OEM parts come with a warranty from the manufacturer, so if something goes wrong you can get it replaced or repaired at no extra cost. The downside is that OEM parts tend to be more expensive than aftermarket ones due to their higher quality standards.

- Aftermarket replacement parts are not made by the original manufacturer but instead by third-party companies that specialize in producing compatible components for various vehicles. These components may not fit as perfectly as an OEM part would but they can still provide good performance at a lower cost than an OEM part would. However, since these components are not made by the original manufacturer there is no guarantee of their quality or durability and they may need to be replaced sooner than an OEM part would have lasted. Additionally, aftermarket replacement parts usually do not come with any kind of warranty from their manufacturers so if something goes wrong you will have to pay for repairs out-of-pocket.

In conclusion, when deciding between using an OEM or aftermarket replacement exhaust system for your vehicle it is important to consider both options carefully before making a decision based on price alone; while aftermarket components may offer savings in terms of the cost upfront they may end up costing more in terms of repairs down the line due to their lack of warranty coverage compared to an OEM component which comes with one from its manufacturer.