We’ll go through the bad AC compressor symptoms and how to replace them in this article. A constant supply of refrigerant is required for every vehicle’s air conditioning system to work properly. The cool air that flows out of the dashboard vents is made possible by this refrigerant.

A component called an air conditioner compressor is the only method for this refrigerant to continue flowing properly.

This component provides pressure, which forces the refrigerant to flow smoothly. It also warms the refrigerant, which is necessary for cool cabin air production. You should have a consistent flow of cool air coming from the vents as long as the AC compressor is functioning. However, an AC compressor, like any other machine, might break down.

- AC Components

- How Does It Work

- Where Is It Located?

- Symptoms

- Tips

- How To Fix?

- What Is The Cost?

- Final Verdict

The Operation Of An Air Conditioning System

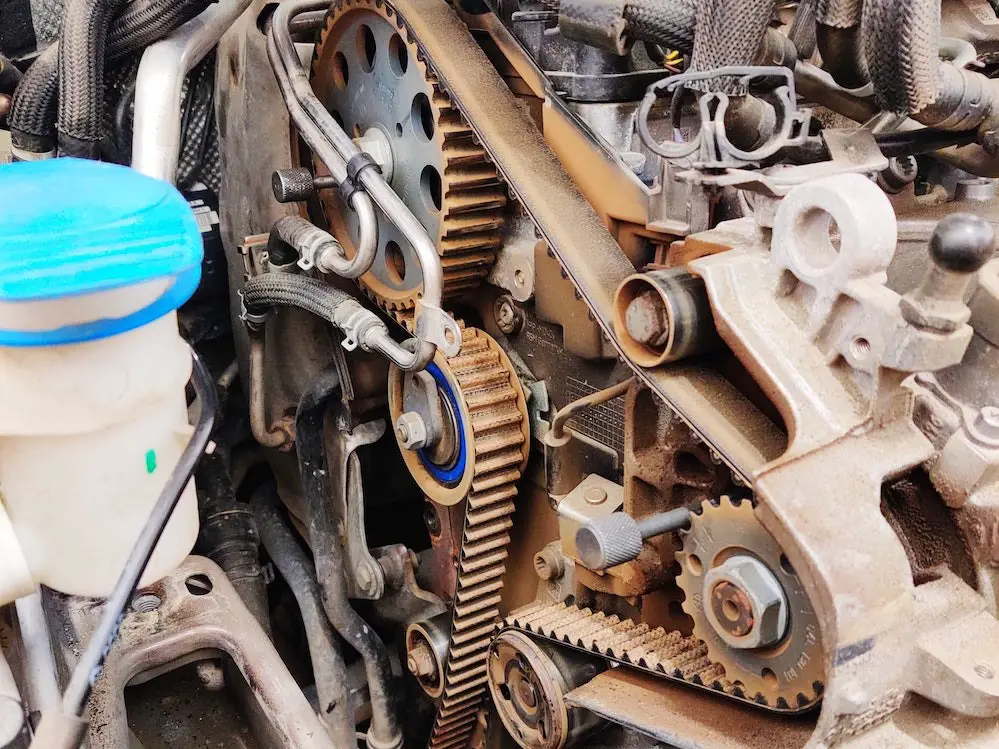

A vehicle’s air conditioning system operates similarly to a refrigerator. The vehicle’s engine powers the AC compressor, connected to it through a belt on the front of the crankshaft. It’s what keeps the cycle of hot and cold refrigerant movement going.

When the engine is operating, the compressor pulley is coupled to the crankshaft and always spins. When the AC is turned to “on”, a compressor clutch links the pulley to the compressor driving shaft, allowing the compressor to run.

1. Compressor

The compressor heats up the gaseous refrigerant it receives from the evaporator by pressurizing it. The heated gas is subsequently sent to the condenser.

2. Condenser

As the hot refrigerant travels through it, the condenser becomes hot, and this heat is then transferred to the cool air being pumped into it as the automobile drives. The evaporation valve at the condenser’s end further cools the refrigerant vapor, turning it back into a liquid.

3. Evaporator

Warm air is blasted over the chilled liquid refrigerant as it enters the evaporator. The boiling point of the evaporator is substantially lower because it is under low pressure. The heat from the air causes the liquid refrigerant to boil, evaporate, and transform into a relatively chilly gas.

The warm air that was pushed over the refrigerant has now been replaced by cool air that is blown inside the cabin to keep it cool.

What Does An AC Compressor Do?

The compressor in your car’s air conditioning system is the system’s heart. It’s essentially a miniature compressor powered by your auxiliary drive belt. Your auxiliary drive belt pulls power from your crankshaft when your engine rolls over and sends it to the pulley on your AC compressor.

Your AC compressor has a clutch installed in the pulley since not everyone uses their A/C all of the time they’re driving. As you turn on and off your air conditioner, this clutch engages and disengages the compressor. If your air conditioner is turned off, the compressor’s pulley will spin without turning the compressor’s internals.

The AC compressor is meant to boost the pressure and temperature of the refrigerant within the system when cooling. The heat that the refrigerant has gathered up from your evaporator can be released once it reaches your vehicle’s condenser because the gas-based refrigerant molecules are closely packed.

Location Of The AC Compressor

The compressor for your air conditioner is normally positioned on the auxiliary drive belt. It will be powered by an electrical socket and will have two refrigerant pipes linked to the body. The AC compressor is normally found near the engine’s bottom, below the alternator and power steering pump, therefore you may look for it from underneath your car.

What Are The Bad AC Compressor Symptoms?

AC compressors are subjected to a great deal of strain. Car air conditioning systems are continually turned on and off, and this power fluctuation can cause the compressor to wear down quickly and lead it to fail after a certain number of years.

People who use their air conditioners frequently will have difficulties with them sooner than those who do not. If your air conditioner compressor is starting to fail, there will be several warning signals. The following are ten common bad AC compressor symptoms.

1. Odd Sounds

Your air conditioner’s compressor is most likely failing if you turn it on and hear a lot of strange noises. To turn, the compressor depends on a sealed bearing and other components. It will be more difficult for the compressor to perform correctly if the internal bearings or parts are broken or worn out.

Strange noises are only the start of bad AC compressor symptoms. Therefore, you should treat this symptom as an early warning sign that your AC compressor needs to be replaced.

2. Vents Blowing Hot Air

Your air conditioner compressor is certainly failing if you turn it on and only get hot air flowing out of the vents after a few minutes. The cool air you desire will not produce if the refrigerant cannot flow through the air conditioning system due to a faulty compressor. As a consequence, you’ll be left with hot air.

This could be a gradual process, with the cool air gradually becoming warmer. The air will become completely hot after a while, with no coolness at all.

3. Fluid Leakage

Sensors in your vehicle’s air conditioning system determine how much refrigerant is in the pipes. If one of these pipes develops a leak and your vehicle loses its refrigerant, your lower pressure switch will detect this and turn off your compressor to avoid damaging it by running dry.

Due to the components’ inaccessibility, you’re seeking to inspect, a refrigerant leak on a car can be tough to locate. However, if you’re looking for a leak, the compressor body is a decent place to start.

The compressor may begin to over-compress the refrigerant due to an internal defect, causing significant heat and pressure to develop within the compressor’s body, causing the seals to fail. As a result, the refrigerant is released, and your air conditioner stops working.

4. Belt Squealing Or Skipping

If the AC compressor is damaged and the belt can’t turn with it, you may hear this sound when trying to start the air conditioning system. This is one of the most common bad AC compressor symptoms.

5. Excessive Wear On The Auxiliary Drive Belt

If you’ve recently had to replace your auxiliary drive belt and observed that your new one is wearing out quickly or making a screaming noise, it’s worth inspecting the pulley on your A/C compressor.

Excessive movement in the bearings of your compressor’s pulley might cause the pulley to run at various angles as it wears out. Snatching and grasping of the rubber auxiliary drive belt frequently occur due to this movement, causing it to wear out prematurely. As the rubber belt grinds against the suddenly misaligned pulley, a high-pitched screech may be heard.

Remove the auxiliary drive belt from the AC compressor and physically inspect the pulley to see if there’s any fault. Some compressors allow you to replace the pulleys without having to replace the entire device. However, this is rarely the case, and replacing a worn pulley often necessitates replacing the compressor itself.

6. AC Compressor Clutch Stuck

The AC compressor clutch guarantees that engine power is only used when it is needed. The clutch will be unable to transfer power from the engine to the compressor correctly if it becomes stuck or seized completely. The air conditioner could be stuck in either the “on” or “off” position, causing premature wear to the air conditioning components or not working at all.

Look beneath the hood while the engine is running to determine if the compressor clutch is spinning when the air conditioner is turned on. In most circumstances, if the clutch has stopped like this, you won’t be able to restore it.

7. Engine Bay Odor Of Burning Rubber

It’s possible that the AC compressor is seized, and the serpentine belt will spin on the AC compressor pulley when you try to turn on the air conditioner and detect a burnt rubber smell emanating from the engine bay. The serpentine belt may snap off pretty rapidly as a result of this, so if you’ve been noticing it for a long time, there’s most certainly something else wrong with your car.

8. Tripping The Circuit Breaker

One of the bad AC compressor symptoms is if your exterior condensing unit loses power and trips the circuit. The cause is overheating and excessive power use, which causes the circuit breaker to trip. The trick is not to keep resetting the circuit breaker and turning on the system. The circuit breaker is performing its job to keep you safe from a fire hazard.

9. Damaged Suction Lines

If the compressor fails to operate, the refrigerant line in the AC system can become blocked, resulting in hot airflow in the vehicle. Taking your car to a repair will solve this problem. The repairman knows how to fix the bad AC compressor symptoms by unblocking the refrigerant lines, but if it doesn’t work, the lines will have to be replaced.

10. Defective Wire

When performing home maintenance, you may find any type of damaged wiring. It’s a bad AC compressor symptoms. Bad wiring is a significant safety risk because it can easily result in an electrical fire. When an air conditioner is subjected to electrical difficulties, the compressor may receive too much or too little voltage. This ruins the compressor quickly, necessitating the purchase of a new AC compressor.

What Happens If The Car’s AC Compressor Fails?

The condenser can’t do its duty of changing the gas into a liquid if the refrigerant gas isn’t compressed at the air conditioner compressor. You’ll notice that the air in the automobile isn’t as cool as it should be.

When a car’s air conditioning compressor malfunctions, debris can spread throughout the system, resulting in potentially costly repairs. Diagnosing and fixing an air-conditioning compressor problem early on can reduce the cost of getting your car’s air conditioning operating again.

Here are the ways to see if your car’s air conditioning compressor needs to be replaced:

Step 1: Turn The AC On High While The Engine Is Running

The air conditioner in the car will turn on as a result of this, and the compressor will turn on as well. Under low pressure, the car air conditioner compressor will suck refrigerant from the evaporator, compress it, and send it to the condenser under high temperature and pressure.

Step 2: Keep An Ear Out For Any Strange Noises

Unusual noises can occur for various reasons, so have a look at the list below of bad AC compressor symptoms before assuming you need a new car air conditioning compressor.

- Look for any splits, cracks, or missing nuts or bolts in the clamps and fixing points.

- Examine the hoses and lines to see if engine vibrations are being transferred to the cabin. Hold each line in one hand to see whether the odd noise goes away.

- A belt drives the car’s air conditioner compressor. Unusual noises could be caused by worn belts, clamping devices, tensioner pulleys, or clutches.

If none of these are the source of the strange sounds, have the car inspected by an expert. Noise might be caused by high pressure in the system or contaminants of the air conditioner refrigerant.

Step 3: Check The Air Vents For Cool Air

If the vents aren’t blowing cool air, there are a few bad AC compressor symptoms you may have to rule out:

- When the air conditioner is turned on, make sure the cooling fans are running.

- Check to see if the cabin air filter is clogged (so, it’s worth knowing how to replace cabin air filter).

- Ensure that no leaves, bugs, or dirt have accumulated in the condenser, obstructing ventilation.

Step 4: Look Under The Car For A Visible Leak

If you have a leak or have ruled out the other possibilities, you’ll need to take your car to a qualified mechanic who will test the system and diagnose the issue.

How To Fix Bad AC Compressor Symptoms

The methods for resolving the bad AC compressor symptoms are as follows:

Step 1: Disconnect The Air Intake And All Accessories

To access the serpentine belt for removal, unbolt and remove any tubing or hoses. This tubing is utilized for emissions and air filter intake proposals, and it’s usually easy to remove by releasing a few small bolts or screws. Except in hybrid and electric vehicles, the serpentine belt that drives the compressor must be removed next.

Step 2: Take Out The AC Compressor

Some compressors are visible, while others are hidden beneath a layer of brackets and accessories like an alternator or power steering pump. Remove any other components, such as an alternator, to gain access to the compressor. Loosening and disconnecting wiring connectors is one way to accomplish this.

Find the electrical connector on the front or back of the compressor once these blocking items have been removed. If the engagement coil is in the front, this wiring is used to energize it, and if the engagement coil is in the back, this wiring is used to energize the internal control valve. To disengage the electrical connector safety, use a small pick or screwdriver.

If you can’t see this connector or it’s too difficult to remove, you can do so after the compressor’s mounting bolts have been removed. Depending on the manufacturer’s design, locate and remove the high and low side refrigerant line mounting bolts. This step may need to be done after the mounting bolts have been removed on some models.

After removing the bolts, firmly hold and twist each refrigerant line’s bulkhead to pull upward and separate it slowly. An O ring seal can provide a tight fit and release a small amount of refrigerant. Locate and remove lower and higher mounting bolts once all wiring harness connectors and refrigerant lines have been removed.

Remove the last mounting bolt while holding the item. Remove it from the engine bay after it is entirely loose. It may be necessary to move the engine a small amount in its mounts or even unscrew the engine mounts and place a jack under the oil pan to help lift it somewhat. A radiator or cooling fan cover may also need to be removed.

Step 3: Inspect The Existing AC Compressor For Damage

Once the unit has been removed, inspect the pulley or clutch for rough movement or grinding noises to assess its condition. If this is present, it may indicate that the system has been contaminated with foreign metal debris from the failed unit, which could clog the orifice tube or expansion valve. In these circumstances, an A/C system flush kit, which can be purchased from a local parts store, must be used to flush the system.

It’s best to replace the expansion valve or orifice tube and the receiver drier or accumulator if the system is totally plugged, depending on the system design. Look for metal particles inside the refrigerant lines or the intake and exhaust ports for evident contamination.

Step 4: Setting Up The AC Compressor

To guarantee appropriate installation, compare the new compressor to the old one. Due to updates and minor design adjustments, the replacement device may appear slightly different. The layout of the refrigerant ports on both the intake and exhaust sides is the one item to look for. Also, count the number of ribs on which the belt must ride and make sure the outside diameter is correct on the belt pulley.

It’s a good idea to move some of the mounting bolts from the previous compressor into the engine bay before lowering it into the engine bay. This will make the installation go more smoothly.

Even though the system has peg oil throughout its internal workings and is normally included in the new compressor, it’s a good idea to add a little quantity (1/2 ounce) of compressor oil before installation to guarantee appropriate lubrication, then reattach dust caps. Some units come with lubricant already installed; check the installation instructions for the replacement unit for further details.

Step 5: Replace The O-Ring Seals

The high and low side lines are sealed to the compressor case with O rings. To avoid leaking, these sealing surfaces must be clean and free of debris or damage. Remove the old O ring seals from both the high and low sidelines with a small screwdriver or pick.

To ensure a perfect seal, match the old O rings to the new ones. Keep an eye on the thickness because some O rings are narrower than others in diameter. It’s preferable not to reuse the previous seals because they flatten out with time due to pressure and heat and may leak, necessitating a rework of the operation, which will require vacuuming and recharging the system.

After thoroughly cleaning the fitting, replace the O ring seals on both the low and high side fittings. Apply a small layer of peg oil on the O ring after installation to aid in placement without breaking or cutting the new seal.

Step 6: Set Up The New AC Compressor

While gently lowering the replacement unit into the engine bay, clear any hoses or lines. Once all of the mounting bolts have been hand threaded in, tighten them evenly in a cross pattern with a wrench or socket. This will prevent the housing from distorting and failing prematurely.

Remove the port dust covers and tighten the mounting nuts on both the high and low side refrigerant lines. These bolts don’t need to be super tight; they just need to be snug enough to keep them from coming loose and sealing against the housing.

Before reconnecting the electrical connector to the engagement coil or refrigerant control valve, check sure the electrical connector is clean. Any accessories, such as the alternator, should be gently lowered into the engine bay while installing the mounting bolts and electrical contacts.

Step 7: Complete The AC Compressor Reassembly

Replace any tubes or hoses that were removed during the replacement procedure, and tighten any nuts, screws, clips, or brackets that were previously removed. The system is now prepared for a vacuum down and recharge service.

Because moisture is present inside the system due to the normal atmosphere that entered once it was opened, never simply fill it with refrigerant. This may cause the compressor to fail prematurely, causing the system to malfunction.

Cost Of A New AC Compressor Clutch

The average cost of replacing an AC compressor clutch is between $700 and $1000. Labor prices typically range from $150 to $250, with a new compressor costing between $450 and $850. The compressor clutch should not be repaired; instead, a new compressor should be installed.

Because the compressor is one of the most important air conditioning system components, it is also one of the most expensive. It is, however, simpler to replace. Replacing the AC compressor is a smart idea if you wish to keep driving your vehicle. However, you don’t want to cut corners and repair just the clutch, only to discover later that another element is defective and you’ll need a new compressor.

Signs of Bad Car Air Conditioning Compressor:

- Vehicle air conditioning is typically one of a car’s most durable systems, and the AC compressor is long-lived and hearty.

- Signs that your car air conditioning compressor is bad include relative coldness of the air from the vents and strange noises from under the hood.

- A leak in the system that causes it to lose refrigerant or a faulty AC compressor are the two most likely problems when the air coming out of the vents doesn’t seem as cold as it used to.

- Often, the AC compressor incorporates a sealed bearing that can wear out or seize up and produce a high-pitched squeal or the grinding sound of metal-on-metal.

- If the bearing seizes, it will typically result in the squealing of the drive belt which is suddenly unable to spin the compressor.

- AC compressors can be repaired, but it is most often a better procedure to replace the faulty compressor with a new one.

- The compressor clutch connected to the engine by a belt and pulley can stick in the “on” position, resulting in the compressor turning all the time you are driving, or it can cease to function at all.

- The clutch failure means the compressor is never engaged, resulting in neither good cooling nor good fuel economy.

- While in some instances the clutch can be repaired, the preferred fix is to replace the compressor and clutch as a unit.

- The AC compressor provides the circulation of a refrigerant fluid through the air conditioning system, compressing it from a gaseous state to a fluid state, sending it to the condenser, and returning it to its gaseous state at an expansion valve or “orifice tube.”

Final Verdict:

The air conditioning compressor is one of the critical components of a vehicle’s air conditioning system. It is in charge of pressurizing the AC system and maintaining the refrigerant flowing to function properly. Because the air conditioner functions in a constant cycle of on and off, it is prone to wear every time it is turned on. It will ultimately fail and need to be replaced, just like every other component on a car.

Because the compressor is in charge of pressurizing and distributing the refrigerant, any problems with it will impact the remainder of the AC system. Car maintenance is critical, and many people overlook the need for car air conditioning. When you see bad AC compressor symptoms, it’s recommended to assess and fix it.