Are you always greeted with a check engine light as soon as you start your vehicle? Or are you having issues with the engine itself? Well, those are two of the most common indications of a bad camshaft position sensor. Although this may sound scary, don’t worry. In this article, we will go through everything you need to know about this common issue.

The camshaft position sensor is a small sensor typically located in the cylinder head of an engine. When this sensor goes bad, it can cause a plethora of issues. Here, we hope to discuss some of the most common issues that you may encounter. We will also be discussing the fixes you can carry out, among some other important points.

Before we take a deeper dive into symptoms and fixes, it is important that you have a clear knowledge of the basics of the camshaft position sensor. If you are curious to get to know the inner workings of it as well, follow along!

Camshaft Position Sensor

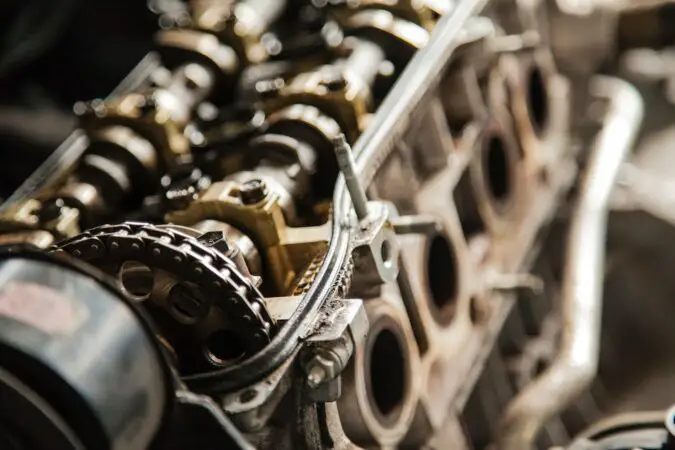

In order to understand the functionality of the camshaft position sensor, we must first look at the camshaft.

What Does The Camshaft Do?

The camshaft is one of the most important parts of a modern engine. It is made up of two components, named the shaft and the cams. Standard camshafts are milled from rough-formed cast steel. You can also find performance camshafts that are milled from a block of solid steel. The function of the camshaft is to activate the intake and exhaust valves of the cylinders. Rotation of this component causes the cams to push against the valves, opening and closing them as needed.

The placement, as well as the number of camshafts, can vary between models. Overhead-camshaft (OHC) engines have their camshaft inside the cylinder head. These types of engines can have two or even four camshafts depending on the configuration.

Single Overhead Cam (SOHC) engines have a single camshaft per cylinder head. The cams in these engines are mounted between the valve stems. On the other hand, Dual Overhead Cam (DOHC) engines contain two cams per cylinder bank located directly over the valve stems.

What Is The Purpose Of The Camshaft Position Sensor?

As the camshaft carries out its rotation inside the engine, it is necessary to relay information about it to the ECU of the engine. This is where the camshaft position sensor comes in handy. It collects information like the rotating position of the camshaft and the sequence of opening/closing to the Engine Control Unit (ECU). The ECU uses this information to ensure that the combustion cycle of the engine is carried out as intended.

The working principle on which this sensor is based is called the Hall principle. A ring gear that is situated on the camshaft rotates with the shaft and causes a voltage change on the Hall IC. This Hall IC is located at the head of the sensor. This affects the voltage transmission of the control unit as well.

With this information, you can understand that a bad camshaft position sensor can have severe consequences on your engine. There is a possibility that your vehicle might be suffering from this issue without your knowledge. But don’t worry! In the next section, we will be discussing the symptoms of this issue so that you will be able to easily identify this issue.

Bad Camshaft Position Sensor Symptoms

There are a number of symptoms that you can use to diagnose a bad camshaft position sensor. We will be going through each of them in detail to provide you with the most knowledge.

Symptom #1 – Problems With Starting The Engine

One of the most obvious bad camshaft position sensor symptoms that you will be met with is problems with starting the engine. The root cause of this issue is the ECU not getting the signal from the sensor to activate the ignition system.

This in return causes the ignition system of the vehicle to not produce a spark. Obviously, without a spark, the combustion cycle cannot commence, resulting in the engine not starting. Some modern vehicles look to remedy this issue by using the signal from the crankshaft position sensor.

Symptom #2 – Check Engine Light

As you already know, the check engine light on your dashboard can turn on due to a variety of reasons. If this has happened to your vehicle, there is a possibility that it is due to a bad camshaft position sensor.

By reading the error codes with the use of an OBD-II scanner tool, you can make sure that the camshaft position sensor is the culprit. In most cases, this scanner will be present with your nearest mechanic.

We would recommend you avoid driving your vehicle with a check engine light on. We say that driving the vehicle with a check engine light may result in severe damage to the internals of your engine.

Symptom #3 – Poor Fuel Economy

As we discussed earlier, a bad camshaft position sensor may result in false information being sent to the ECU. Sometimes, this may result in excess fuel being released into the cylinders for combustion. As you would probably have guessed, this leads to wastage of fuel.

Not only that, excess fuel leads to a sub-optimal combustion cycle. All these factors will cause you to get bad fuel mileage. This symptom may be harder to observe than the others we’ve discussed. However, if your fuel milage has been slowly getting worse, we recommend getting your camshaft position sensor checked by a professional.

Symptom #4 – Gear Shifting Issues

On some occasions, camshaft position sensor issues can cause issues in the transmission of your vehicle. This can lead to your vehicle being stuck in one gear, essentially rendering it undrivable. A temporary solution for this problem is to turn off the engine and restart it after a while.

Symptom #5 – Engine Stall

Rarely, a bad camshaft position sensor can cause the engine of your vehicle to stall. These engine stalls can be proceeded by the engine jerking or surging while driving. Stalling can also happen when you are parking the vehicle. All these symptoms are caused due to combustion not happening inside the engine, due to false sensor readings.

Symptom #6 – Rough Idling Of The Engine

A roughly idling engine should never be discarded. Unsynchronized combustion cycles happening in the engine are the main cause of a rough idle. A faulty fuel pump, EGR valve, or a camshaft position sensor may be the root cause of this issue. Whatever the cause, Identifying the cause of a rough idle can be a time-consuming task.

Symptom #7 – Reduced Power Output

Sub-optimal combustion of the engine due to a bad camshaft position sensor can result in the engine of your vehicle producing less power. This may be noticeable to you when trying to accelerate. On some occasions, your engine can go into “limp mode”. This is a feature implemented by the manufacturer to prevent further harm from being caused to the engine.

Whether you are suffering from just one or even a few of these symptoms, it is important that you immediately get your vehicle inspected by a mechanic. The chances of the main cause being a bad camshaft position sensor are extremely likely. With that, let us move into the next section.

Camshaft Position Sensor Location

You may be curious about the location of the camshaft position sensor in your engine. We touched on this topic briefly in a previous section, but let us discuss it in more detail.

The location of this sensor varies from one vehicle manufacturer to another. It can be placed around the engine block, the lifter valley, a specially designed compartment, or at the back of the cylinder head of the engine. On most occasions, this sensor is located at the top of the valve cover. You can locate the camshaft position sensor by following the electrical wires, or by simply referring to the owner’s manual.

We told you previously that you can identify a bad camshaft position sensor using an OBD-II scanner. You might have some doubts about this matter. In that case, follow along!

Camshaft Position Sensor Code

The OBD-II scanners point you to specific errors by indicating relevant codes. When it comes to this specific issue, it can indicate one of several error codes. Let us go through them one by one to get familiar with each.

P0340 CMP

This code indicates a malfunction of the camshaft position sensor “A” circuit. Damaged wiring or loose connections can also lead to the P0340 error code popping up during an OBD-II scan. This error can be generated due to issues with components related to internal engine timing as well. Some of the above-mentioned symptoms like engine stalls, rough idling, and the check engine light can also happen due to the causes of this error.

P0341 CMP

This is a code that indicates a performance problem or a circuit range problem. When the sensor is not properly timed or is out of range, the P0341 CMP error code will be shown. Other engine-related issues like VVT mechanism problems, a stretched timing belt, improper timing, or electrical interference can also result in this error code.

P0342 CMP

When a low input at a circuit is recognized, this error code will be shown. Hard starts of the engine, stalls, misfires, and loss of power when driving are the most likely symptoms to occur along with this error code. A faulty starter motor, weakness of the battery, a shorted wiring harness, or issues with the starting system circuit may also lead to a P0342 error being shown.

P0343 CMP

This is an error code that indicates circuit high output. In simpler terms, this code is given out when a problem with the camshaft position sensor signal is detected by the PCM. The P0343 error can also be caused by an internal engine problem or a problem with a timing component. A PCM in need of a software update can also be a culprit on this occasion.

P0344 CMP

The P0344 error code is triggered when there is a loss of signal to the PCM from the camshaft position sensor which is located at the bank of the engine that contains cylinder 1. This bank is also referred to as bank 1. A bad camshaft position sensor or a PCM issue may be the root cause of this error code being generated. You can expect the check engine light to turn on and the engine to stall when you are presented with a P0344 error.

Using these codes, you can carry out the relevant repair on your vehicle and fix the issue. So far, we have looked at the most common symptoms caused by a bad camshaft position sensor. We have also looked at the common OBD-II error codes put out due to a bad sensor. With that information, you may be interested in replacing the faulty sensor. If that is the case, let’s proceed to the next section.

Camshaft Sensor Replacement Cost

If you have finally confirmed that the camshaft position sensor of your vehicle is indeed faulty, it might be necessary to replace it with a replacement part. Although the camshaft position sensor in itself is not a very expensive part, the specific cost can vary according to the make and model of the vehicle. Typically, a replacement sensor can be had for between $75 to $120. Nonetheless, the place of purchase and the brand of the product can also affect the price.

The installation of the camshaft position can either be done by a professional or by yourself in the comfort of your home. If you are expecting to get the replacement done by a professional mechanic, expect to pay a labor cost of around $30 – $130. This cost can vary according to the place you go to get the installation done as well as by your place of residence. This is because different counties have different labor laws, which affects the cost of labor.

But, if you are a mechanically-inclined individual, you will be able to easily carry out a camshaft position sensor replacement at home. Here, we will guide you through the steps of doing this replacement by yourself.

Replacing A Bad Camshaft Position Sensor At Home

First, you should locate where the sensor is placed on your engine. You can refer to the owner’s manual or google this information. You might have to remove some components like hoses to access the faulty sensor. After you have reached it, disconnect its electrical connection.

Now, you can unscrew the sensor from its mounts and remove it. Then simply replace it with the new product and fit all the components you removed. After the replacement, you will be able to immediately feel a positive improvement in the performance of your engine.

After replacing the bad camshaft position sensor with a new one, we recommend that you periodically test it to see whether it is functioning as intended. In the next section, we will talk about the testing process in more detail.

Camshaft Position Sensor Test

You can test the camshaft position sensor visually as well as by using some testing equipment. We will advise you on both these methods in detail.

1. Visually Inspecting For A Bad Camshaft Position Sensor

A visual inspection is one of the easiest preventive measures you can do to ensure that the sensor is performing optimally. When inspecting visually, pay close attention to the wiring that carries signals to and from the sensor. Check for corrosion, damage, or contamination on the wire connectors. Wiggle the connector slightly to check for any loose connections.

After you have checked the connector, it is time to look at the wires themselves. Check for breaks along the length of the wire to ensure that no electrical shorts are happening. If you see any burns on the wires, they might need to be replaced.

Before discussing testing procedures, it is important for you to understand that there are generally two types of camshaft position sensors available on the market. It is important to understand their difference as the testing procedures are unique to each type of sensor.

2. Testing A Magnetic Type Camshaft Sensor Using Equipment

A camshaft position sensor with two wires is called a “Magnetic type” sensor. This type of sensor is capable of producing its own voltage in the form of an alternating current (AC). As a result, you need to have a digital multimeter with you for testing.

You can read the AC voltage produced by the sensor through this equipment. After getting the results, compare them with the recommended voltage listed in the repair manual of your vehicle. A slight variation will most likely not be a cause for concern. However, a significant difference may indicate an issue with the sensor.

3. Testing A Hall-Effect Type Camshaft Sensor Using Equipment

The other type of camshaft position sensor is called the “Hall effect type”. These Hall-effect type sensors can be easily identified by their three wires. These wires are used to carry the ground, power, and signal voltage respectively.

The digital multimeter can be used to check this type of sensor as well. Unlike the magnetic type sensors which produce an AC voltage, these sensors produce a squared digital signal. Check the readings with the electrical readings specified in the repair manual, and you will be able to determine whether a replacement is necessary.

Other than the above-mentioned methods, you can carry out other tests to check for a bad camshaft position as well. A camshaft position sensor resistance test measures the resistance of the component to electricity. The digital multimeter comes in handy on this occasion as well. Preferably, the resistance value should fall between 200-900 ohms. An open sensor will give out a reading of infinite resistance, in which case it should be replaced.

On the other hand, a bench test of the camshaft position sensor is performed after removing the component from the vehicle. Ideally, when passing a metal object close to the magnet of the sensor you should a pulse in the voltage signal. If that is not the case, then your sensor may need to be replaced. By carrying out these tests periodically, you will be able to detect a bad camshaft position sensor before it causes any serious issues.

Conclusion For Bad Camshaft Position Sensor

During the length of this article, we discussed the issue of bad camshaft position in detail. We started off by looking into the functionality of the camshaft as well as the camshaft position sensor itself. After that, some symptoms that may be caused due to a faulty sensor were discussed.

Later, some OBD-II codes related to the camshaft position sensor and its replacement procedure were discussed. Finally, some testing methods that can be used to identify a bad camshaft position sensor were discussed.

Camshaft Position Sensor Facts:

- A camshaft position sensor monitors the camshaft position and speed, providing data to the vehicle’s engine control module to control fuel and ignition timing.

- Symptoms of a failing camshaft position sensor include a lit Check Engine light, poor drivability, transmission shifting problems, bad fuel economy, and engine failure to start.

- On modern auto-start/auto-stop engines, the camshaft position sensor determines which cylinder is in its power stroke relative to the crankshaft position, delivering fuel and spark to start the engine when the accelerator is pressed.

- A failing camshaft position sensor can cause mismatched fuel delivery and ignition timing, resulting in sputtering, poor acceleration, lack of power, stalling, or even engine shutdown.

- Inaccurate data from a failing camshaft position sensor can cause fuel injectors to stay open too long, leading to excess fuel in the combustion chamber, engine knocking, and potential damage.

- Ignoring symptoms of a failing camshaft position sensor can result in engine failure to start and can be dangerous if it occurs while driving.

- The Check Engine light is the most common indicator of a failing camshaft position sensor, and it’s best to take the vehicle to a professional when this light illuminates.

- DIY scan tools can connect to the ECM to diagnose the problem, but it’s best to have a professional handle the repairs.

- On-board diagnostics II systems can detect part deterioration before a part completely fails, preventing expensive engine or transmission repairs.

- Eventually, ignoring symptoms of a failing camshaft position sensor can lead to engine failure to start, and it’s important to replace the sensor when symptoms appear.

FAQS On Bad Camshaft Position Sensor

Here are some popular FAQs:

What Is A Camshaft

A camshaft is a device located inside an internal combustion engine that converts a rotational motion into a linear motion. It is made up of two parts. The shaft is a long metal rail, which is typically made of a durable material like steel or cast iron. The other components which make up the camshaft are called cam lobes. These egg-shaped objects are located on the shaft and are spaced apart accordingly to align with the valves of the engine. The camshaft rotates in synchronization with the crankshaft to carry out its function. To achieve this, they are connected together by the timing belt.

What Does A Camshaft Do

The main duty of the camshaft is opening and closing the intake valves of the engine’s cylinder head. Due to the rotation of the camshaft, its lobes press against the valve lifters. This causes the valves to open to let air and fuel enter the cylinder. As the lobes rotate away from the lifters, the valve springs return the valve covers to the original position. This process is essential for the engine to produce power as intended.

How To Reset Camshaft Position Sensor

Resetting the camshaft sensor should be carried out according to the error codes read by the scanning equipment.

What Happens When A Camshaft Sensor Goes Bad

When a camshaft sensor goes bad, the check engine light will turn on. Other symptoms like rough idle of the engine, frequent stalls, loss of power, and poor fuel economy may also be caused due to a bad camshaft position sensor.