- How B&M Torque Converters Improve Performance

- Benefits of Installing a B&M Torque Converter

- Different Types of B&M Torque Converters

- Upgrading to a High-Performance Torque Converter

- What to Look for When Shopping for One

- Common Problems with B&M Torque Converters

- Tips for Maintaining Your B&M Torque Converter

- Comparing Aftermarket vs OEM Replacement Parts

- Q&A

How B&M Torque Converters Improve Performance and Efficiency

A B&M torque converter is a popular choice for those looking to improve the performance and efficiency of their vehicle. These torque converters are designed to increase the amount of power that is transferred from the engine to the transmission, allowing for improved acceleration and fuel economy.

- The main benefit of B&M torque converters is their ability to increase torque multiplication. This means that more power is transferred from the engine to the transmission, resulting in improved acceleration and fuel economy. The increased torque multiplication also allows for higher top speeds, as well as better control over shifting points when driving at high speeds. Additionally, these converters can help reduce wear on other components such as clutches (as well as the torque converter clutch solenoid) and transmissions by reducing slippage during shifts.

- Another advantage of B&M torque converters is their ability to reduce heat buildup in engines due to increased efficiency. This helps keep engines running cooler which can lead to longer engine life and improved performance overall. Additionally, these converters can help reduce noise levels due to reduced vibration caused by increased efficiency in transferring power from the engine to the transmission.

- Finally, B&M torque converters are designed with durability in mind so they will last longer than other types of converters on the market today. They feature heavy-duty construction materials such as steel or aluminum which provide superior strength and reliability compared with other types of converters available today.

Overall, a B&M torque converter offers many benefits including improved performance and efficiency while also providing long-term durability for your vehicle’s drivetrain system. If you want to learn more, do check out our overview of what is a torque converter.

The Benefits of Installing a B&M Torque Converter in Your Vehicle

A B&M torque converter is an essential component of any vehicle’s transmission system. It is responsible for transferring power from the engine to the transmission, allowing your car to move forward. Installing a B&M torque converter in your vehicle can provide numerous benefits, including improved performance and fuel economy.

- One of the primary advantages of installing a B&M torque converter is improved performance. The increased stall speed provided by this type of converter allows for more efficient acceleration and higher top speeds. This can be especially beneficial if you are looking to improve your vehicle’s overall performance or if you are looking to race competitively. Additionally, the increased stall speed also helps reduce wheel spin when accelerating from a stop, which can help improve traction and handling on wet or slippery surfaces.

- Another benefit of installing a B&M torque converter is improved fuel economy. The increased stall speed allows for more efficient use of engine power, resulting in less fuel being used during acceleration and cruising speeds alike. This can result in significant savings over time as well as reduced emissions due to less fuel being burned overall.

- Finally, installing a B&M torque converter also provides better reliability than other types of converters due to its superior construction quality and materials used in its manufacturing process. This ensures that it will last longer than other types of converters while providing consistent performance throughout its lifespan without needing frequent repairs or replacements due to wear-and-tear issues common with other types of converters over time.

Overall, there are many benefits associated with installing a B&M torque converter in your vehicle including improved performance, better fuel economy, and greater reliability compared to other types of converters available on the market today.

If you are looking for an upgrade that will provide long-term value while improving your car’s overall driving experience, then investing in a high-quality B&M torque converter may be just what you need.

Understanding the Different Types of B&M Torque Converters

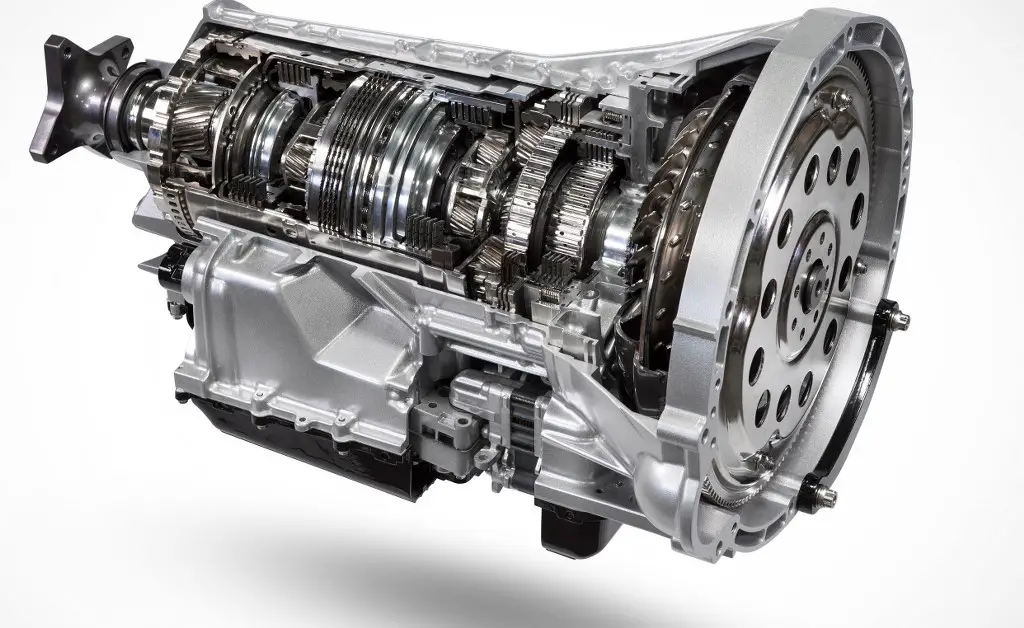

Torque converters are an important component of a vehicle’s transmission system, allowing the engine to transfer power to the wheels. There are several different types of torque converters available, each with its own unique characteristics and advantages.

Understanding the differences between these types can help you make an informed decision when selecting a torque converter for your vehicle.

- The most common type of torque converter is the lock-up converter. This type uses a clutch to engage and disengage from the engine, allowing it to operate at higher speeds without slipping or stalling out. Lock-up converters provide improved fuel economy and performance due to their ability to maintain a constant speed without slipping or stalling out.

- Another popular type of torque converter is the multi-disc converter. This type uses multiple discs instead of one large disc, which allows it to handle higher levels of torque more efficiently than other types of converters. Multi-disc converters also provide improved fuel economy due to their ability to reduce slippage and improve efficiency at high speeds.

- The third type is known as a stall speed converter, which is designed for vehicles that require high levels of power output from low RPMs (revolutions per minute). Stall speed converters use centrifugal force generated by spinning discs inside the unit in order to increase engine output at lower RPMs while maintaining efficiency at higher RPMs as well. These units are often used in drag racing applications where maximum power output is required from low RPMs in order for quick acceleration off the line.

- Finally, there are billet steel torque converters that offer superior strength and durability compared with other types due to their construction using billet steel components rather than cast aluminum or plastic parts found on some other models. Billet steel units also tend to be more expensive than other types but offer greater reliability over time due to their increased strength and durability compared with other materials used in manufacturing them.

In conclusion, there are several different types of B&M torque converter available on today’s market each offering its own unique advantages depending on your specific needs and requirements when selecting one for your vehicle’s transmission system.

Understanding these differences can help you make an informed decision when choosing a B&M torque converter that best suits your needs.

Exploring the Advantages of Upgrading to a High-Performance B&M Torque Converter

Upgrading to a high-performance B&M torque converter can provide numerous advantages for your vehicle. This type of torque converter is designed to increase the power and efficiency of your engine, allowing you to get more out of your car. Here are some of the benefits that come with upgrading to a high-performance B&M torque converter:

- Increased Horsepower: A high-performance B&M torque converter will increase the horsepower output from your engine, allowing you to accelerate faster and reach higher speeds. This can be especially beneficial if you’re looking for improved performance on the track or on winding roads.

- Improved Fuel Economy: The increased efficiency provided by a high-performance B&M torque converter will also help improve fuel economy, as it reduces drag on the engine and allows it to run more efficiently. This means that you’ll be able to go further on each tank of gas, saving money in the long run.

- Reduced Heat Buildup: The improved design of a high-performance B&M torque converter helps reduce heat buildup in your engine, which can lead to better overall performance and longer component life spans.

- Enhanced Durability: High-performance torque converters are built with stronger materials than standard converters, making them more durable and reliable over time. This means that they’ll last longer before needing replacement or repair work done on them.

Overall, upgrading to a high-performance B&M torque converter is an excellent way to get more out of your vehicle while also improving its longevity and reliability over time.

With increased horsepower output, improved fuel economy, reduced heat buildup, and enhanced durability all being benefits associated with this upgrade option; it’s easy to see why so many drivers choose this route when looking for ways to improve their car’s performance capabilities.

What to Look for When Shopping for a New B&M Torque Converter

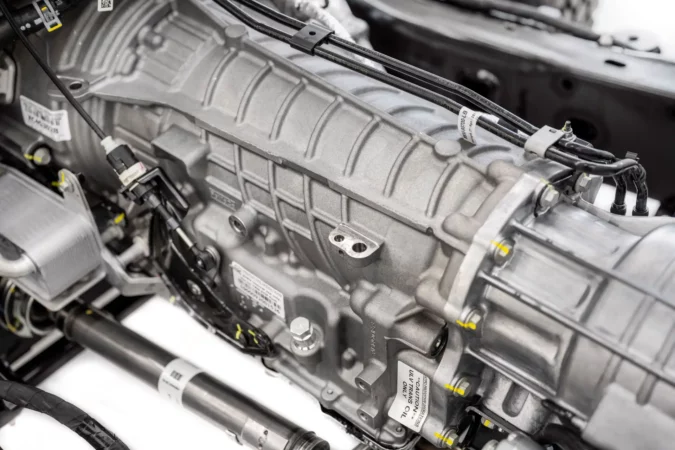

When shopping for a new B&M torque converter, there are several important factors to consider. First, it is important to determine the type of vehicle and engine in which the torque converter will be used in. This will help ensure that the correct size and specifications are chosen for optimal performance.

Next, it is important to consider the stall speed of the torque converter. Stall speed refers to how quickly a vehicle can accelerate from a stop when using a particular torque converter. A higher stall speed indicates better acceleration potential, while lower stall speeds may be more suitable for vehicles with smaller engines or those that require smoother operation at low speeds.

It is also important to consider the material used in constructing the torque converter as well as its overall design and construction quality. High-quality materials such as steel or aluminum should be chosen over cheaper alternatives such as plastic or composite materials which may not provide adequate durability over time.

Additionally, look for converters with reinforced fins and other features designed to increase strength and reduce wear on components over time. Finally, it is essential to research any warranties offered by manufacturers before making a purchase decision on a new B&M torque converter.

Many companies offer limited warranties on their products which can provide peace of mind if any issues arise after installation or use of the product down the line.

Common Problems with B&M Torque Converters and How to Fix Them

B&M torque converters are a popular choice for many automotive enthusiasts, as they provide improved performance and reliability. However, like any other component in a vehicle, B&M torque converters can experience problems from time to time. In this article, we will discuss some of the most common issues with B&M torque converters and how to fix them.

- One of the most common issues with B&M torque converters is that they can become noisy over time. This is usually caused by worn or damaged bearings inside the converter itself. To fix this issue, you will need to replace the bearings or have them professionally serviced by an experienced technician. Additionally, it may be necessary to replace other components such as seals and gaskets if they are worn or damaged as well.

- Another issue that can occur with B&M torque converters is slippage during acceleration or deceleration. To learn more, you can check out our guide on transmission slipping, what causes a transmission to slip, as well as the symptoms of a slipping clutch. This is usually caused by a lack of lubrication in the converter itself or due to excessive heat buildup within it. To fix this problem, you should check your vehicle’s owner’s manual for recommended lubricants and follow their instructions for the proper application and maintenance of your converter’s internal components. Additionally, you may need to install an aftermarket cooling system if your vehicle does not already have one installed in order to reduce heat buildup within the converter itself.

- Finally, another common issue with B&M torque converters is that they can become stuck in one gear when shifting between gears while driving at higher speeds (such as highway speeds). This problem is typically caused by worn synchronizers within the transmission system which prevent smooth shifting between gears at higher speeds due to increased friction between moving parts inside the transmission system itself. To fix this issue, you should have your transmission inspected by an experienced technician who can diagnose any underlying problems causing this issue. They may recommend replacing certain components such as synchronizers, seals, gaskets, etc., depending on what needs repair.

Overall, these are some of the most common issues associated with B & M torque converter systems. If you experience any of these problems, it’s important that you take action quickly so that further damage does not occur. By following the steps outlined above, you should be able to get your car back up and running smoothly again in no time.

For more insight into torque converter-related issues, check out our guide on the symptoms of a bad torque converter. Diagnosing a faulty torque converter can include using an OBD scanner to scan for error codes, such as a P0741 code, among others.

Tips for Maintaining Your B&M Torque Converter

1. Check the fluid level regularly. Make sure to check the fluid level in your B&M torque converter at least once a month, or more often if you are using it frequently. The fluid should be at the proper level and free of any debris or contaminants.

2. Change the oil regularly. It is important to change the oil in your B&M torque converter on a regular basis, as this will help keep it running smoothly and efficiently for longer periods of time. Be sure to use only high-quality oil that is specifically designed for use with torque converters when changing out the old oil for new.

3. Inspect all components regularly for wear and tear. Regularly inspect all components of your B&M torque converter, including seals, gaskets, bearings, and other parts that may be prone to wear over time due to friction or heat buildup from the operation of the unit itself. Replace any worn parts immediately so as not to cause further damage or reduce the efficiency of operation over time due to a lack of maintenance or repair work being done on them as needed.

4. Clean all components thoroughly before reassembly after repairs have been made. After making repairs on any part of your B&M torque converter, make sure that you clean all components thoroughly before reassembling them back into place so as not to introduce dirt or debris into sensitive areas which could cause further damage down the line if left unchecked.

Comparing Aftermarket vs OEM Replacement Parts for Your B&M Torque Converter

When it comes to replacing your B&M torque converter, you have two main options: aftermarket and OEM (Original Equipment Manufacturer) replacement parts. Each option has its own advantages and disadvantages, so it is important to understand the differences between them before making a decision.

Aftermarket parts are typically less expensive than OEM parts, but they may not be as reliable or durable. Aftermarket parts are usually made with lower-quality materials and may not fit as well as an OEM part. Additionally, aftermarket parts may not be covered by any warranty or guarantee from the manufacturer.

On the other hand, OEM replacement parts are more expensive but offer greater reliability and durability due to their higher quality materials and exact fitment for your specific vehicle model. They also come with a manufacturer’s warranty that covers any defects in workmanship or material for a certain period of time.

Ultimately, when deciding between aftermarket vs OEM replacement parts for your B&M torque converter, you should consider both the cost and quality of the product before making a purchase decision. For further context, check out our explainer on the torque converter replacement cost.

If you want reliable performance at an affordable price point then an aftermarket part might be right for you; however, if you want maximum performance then investing in an OEM part is likely worth the extra cost.

Q&A

1. What is a B&M torque converter?

A B&M torque converter is a device that increases the torque output of an engine by transferring power from the engine to the transmission. It works by using centrifugal force to increase the speed of rotation of the input shaft, which in turn increases torque output.

2. How does a B&M torque converter work?

A B&M torque converter works by using centrifugal force to increase the speed of rotation of the input shaft, which in turn increases torque output. The converter consists of two sets of blades that spin at different speeds and are connected via a clutch plate and stator assembly. As engine RPMs increase, so does the speed at which these blades spin, creating more torque for your vehicle’s transmission system.

3. What are some benefits of using a B&M torque converter?

Using a B&M torque converter can provide several benefits including improved acceleration, increased fuel economy, smoother shifting, and increased overall performance from your vehicle’s transmission system. Additionally, it can help reduce wear on other components such as clutches and gears due to its ability to transfer power more efficiently than traditional methods like manual transmissions or CVT systems do.

4. Are there any drawbacks associated with using a B&M torque converter?

The main drawback associated with using a B&M torque converter is that it can be expensive compared to other types of converters available on the market today due to its higher quality components and construction techniques used during manufacturing processes such as CNC machining and heat treating for added durability over time. Additionally, they require regular maintenance in order for them to continue functioning properly over time as well as periodic fluid changes depending on usage conditions or mileage driven since the last service interval was completed.

5. How often should I replace my B&M Torque converter?

It is recommended that you replace your B&M torque converter every 50-60 thousand miles or when you notice any signs or symptoms indicating it may need replacing such as slipping gears while driving or difficulty shifting between gears when accelerating/decelerating. Additionally, if you have been experiencing any issues with your vehicle’s performance, then it may be beneficial for you to have your converter inspected sooner rather than later to ensure everything is functioning properly before further damage occurs.

6. What type of fluid should I use in my torque converter?

It is recommended that you use ATF (Automatic Transmission Fluid) specifically designed for use with high-performance applications such as those found within racing vehicles when filling up your torque converter. This type of fluid will help ensure optimal performance from both your engine and transmission system while also providing additional protection against wear caused by friction between moving parts within these systems over time.

7. Can I install my own torque converter?

Yes, however, we recommend having an experienced mechanic perform this task if possible due to the complexity involved during the installation process (such as proper alignment) along with the potential safety risks associated if done incorrectly. Additionally, certain tools may be required depending on make/model year so please consult the manufacturer’s instructions prior to attempting this task yourself if necessary.

8. Is there anything else I should know about my new torque converters?

Yes. It’s important not only to maintain proper fluid levels but also to check periodically for leaks around seals/gaskets located near where the unit mounts onto the transmission housing itself – this will help prevent any potential damage caused by low levels resulting from leakage over time. Also, keep an eye out for signs of excessive heat buildup (such burning smell) coming from the area – this could indicate an issue related to either the cooling fan malfunctioning or improper airflow through the radiator core itself.