Wondering what is a torque converter? It’s the heart of the automatic transmission. This post will cover everything you need to know about the torque converter. From the components that make it, how it works, and we’ll briefly touch on the repair costs in case you suspect you have a bad torque converter.

By the end of this post, you should know everything you need to know about the torque converter. Here’s our table of contents to help you find the relevant information:

What Is A Torque Converter?

The torque converter is essentially a device that uses fluid to transfer power from the engine to the transmission—and ultimately the wheels—in a car that uses an automatic transmission.

There are three major types of automatic transmission: conventional (sometimes referred to as planetary gear-type transmissions), Continuously Variable Transmission (CVT), and dual-clutch transmission (DCT). Both conventional and CVT transmissions use torque converters, but the DCT system doesn’t. We’ll briefly touch on that later on.

If you look at your car’s brochure or spec sheet, and it simply states something like “6-speed automatic” and doesn’t say CVT, DCT, or DSG, then you have what we call a conventional automatic transmission. And up until the last decade or so they have been the most common type of automatic transmission.

The torque converter’s job is similar to a clutch in a manual transmission, which is to connect and disconnect the transmission from the engine. When you drive an automatic, you’ll notice that the car creeps forwards when you put it in ‘Drive’ even without touching the throttle. This is thanks to the torque converter. Here’s a more in-depth explanation:

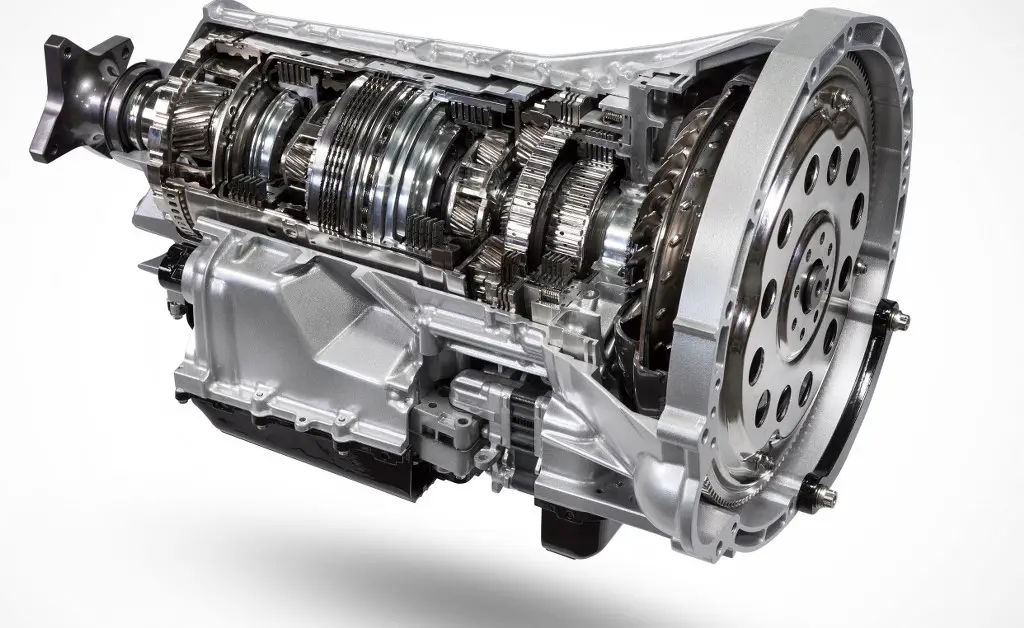

Torque Converter Diagram

The torque converter has four major parts: a pump or impeller, a turbine, a stator or reactor, and a torque converter clutch. The system works by using transmission fluid, and here’s how it works:

- The pump permanently connects to the engine’s flywheel and always spins with the crankshaft.

- When the car is stationary, the torque converter clutch will lock the turbine in place preventing it from spinning. When you put the car in Drive, this disengages the clutch and allows the turbine to move freely.

- The fluid from the pump spins the turbine, but it spins at a much slower rate due to loss of power thanks to laws of fluid dynamics. This is where the stator/reactor comes in.

- The turbine sends the fluid through the reactor, which spins and increases the pressure of the fluid. It sends the fluid back to the pump, and as a result, the turbine spins faster and torque is multiplied. Hence why the assembly is called a torque converter.

- The turbine is connected to the transmission itself, and the rotational motion of the turbine powers the transmission and ultimately makes your car go forward.

We don’t have a diagram of the torque converter. But this video illustrates the parts and how they work:

Don’t feel bad if you have difficulties wrapping your head around this component. It also took us a while to grasp how the system works, they’re pretty complicated.

The gist of it is that it uses an impeller to pump transmission fluid to spin a turbine. Since the turbine is connected to a shaft to the transmission, this spins the planetary gear set in the transmission and ultimately transfers that power to the wheels.

Do Automatic Cars Have A Clutch?

Yes, but not in the same way that the clutch in a manual works. In a manual car (with some pointers on how to drive a manual car), the clutch’s job is to connect the engine’s shaft to the transmission. When you press the clutch pedal, the clutch engages and disconnects the engine from the transmission. Once you release it, the clutch disengages and allows the engine to connect to the transmission again.

In an automatic transmission with a torque converter, there’s a lock-up clutch that locks the rotation of the turbine rather than connecting and disconnecting the engine from the transmission. In other words, there is no direct driveshaft connection between the engine and transmission.

Note that automatic transmissions also have clutch packs. These clutch packs control gear changes inside the automatic transmission. And they operate by using oil pressure from the solenoid which is controlled by the Transmission Control Module (TCM).

Other Types Of Automatic Transmission

As mentioned, the CVT system also works by using a torque converter. The difference is that CVTs use a belt (or sometimes a chain) and a couple of pulleys to transfer power from the engine to the wheels. So, there are no gears inside them. You can learn more in our article about CVT transmissions.

Meanwhile, a dual-clutch system works without a torque converter. It’s actually more similar to a manual transmission, where a multi-clutch pack engages and disengages to control the connection between the engine and the transmission.

The main difference is that the clutch operates automatically and doesn’t require any input from the driver. So it’s just like a conventional automatic to operate. And as the name suggests, this system has two clutches. One for the even gears, the other for odd gears. This system allows for faster gear changes and is usually more power-efficient.

Some of the common brand names for this system are the DCT by BMW, DSG by Volkswagen, and PDK by Porsche. This system is complex and quite expensive, hence why you don’t see it very often. But it’s great for performance cars.

Torque Converter Symptoms

Since it’s the heart of your automatic transmissions, you’re bound to encounter symptoms when there’s a problem with the torque converter. If you think you have a bad torque converter, here are the symptoms to look out for:

- Transmission slip. This is when you press the gas pedal but the car doesn’t actually go forward. A transmission slip is when the gears aren’t engaging properly, and therefore aren’t transferring power to the wheels. It feels like the car is in the Neutral gear.

- Gear shifting issues. The torque converter transfers power to the planetary gear sets inside the transmission, which then engages the clutch pack to operate the gears. A faulty torque converter can cause issues with the planetary gear sets, and ultimately affects gear shifting.

- Loss of power. A bad torque converter might not multiply the torque from the engine properly. This will result in less torque reaching the transmission, and the car will feel like it’s losing power. You’ll notice a lack of power when accelerating.

- Shuddering and weird noises. Modern transmissions work incredibly smoothly. When there’s an issue with the torque converter, it can create vibrations and shudder the car. It can also create a loud whining noise when you accelerate.

- Limp mode. If the problem is bad enough, the car might go into limp mode. This is a self-preservation mode where the Engine Control Unit (ECU) limits engine power and prevents the transmission from engaging the third gear and higher to prevent further damage. The check engine light will usually flash if the car is in limp mode.

Of course, other transmission issues can cause the symptoms above as well. Some are very minor, such as a faulty solenoid that isn’t allowing oil flow to change the gears. This segues us to our next section:

Bad Torque Converter VS Bad Transmission

When talking about torque converter and transmission problems, the term is often interchangeable. A lot of mechanics and DIY enthusiasts will sometimes say it’s a bad transmission when it’s actually it’s a bad torque converter and vice versa.

In a way, it’s not wrong. The torque converter is integral to the automatic transmission’s operation. So, while it’s technically a separate component, the two can’t work without the other. And it’s essentially like they’re one construction.

However, you should always verify whether it’s a torque converter or a transmission problem. Torque converters are typically cheaper to replace than rebuilding or replacing a transmission, which is what you need to do when you have a bad transmission.

We don’t want you to spend thousands of dollars to rebuild a transmission, where in reality it’s actually a faulty torque converter. Unfortunately, testing a torque converter is quite difficult. It will often require removing the torque converter itself, which is a long and arduous process.

We also don’t recommend doing the stall-speed test as you risk blowing the entire powertrain. This process entails maxing out the car’s RPM while holding the brakes. If the engine stalls below the RPM specification, then you have a bad torque converter. Again, this process stresses the powertrain and your risk of blowing it, so we don’t recommend doing this.

Diagnosing The Torque Converter With An OBD Scanner

A much safer method is to use an OBD scanner. Every car since 1996 has had an On-Board Diagnostic (OBD) system, specifically the universal OBD-2 system. This system registers trouble codes when the car’s ECU detects a problem in the car that it can’t fix.

The trouble code will trigger the check engine light, and you can scan the system to find the trouble code. While it doesn’t tell you specifically what’s wrong, it makes the diagnosis process a lot easier. Here’s what to do:

- Locate the car’s OBD port, which is usually behind a plastic panel underneath the dashboard on the driver’s side. Consult with your service manual if you can’t find it.

- Plug the OBD scanner into the port and scan for trouble codes. Certain scanners will require you to input the car’s make, model, year, and VIN.

- The scanner will display the error code. Take note of them if your scanner can’t display what the code means so you can check what the code means later.

Some common torque converter trouble codes include the P074o to P0744, P2769, and P2770. A bad torque converter can cause these issues, but sometimes the problem is as simple as dirty or low transmission fluid.

Note that sometimes transmission issues can cause those codes as well. Discussing these codes will take forever, so we won’t get into that in this article. But if you see the aforementioned codes, you have good reason to suspect it’s a bad torque converter.

In the end, it’s just a lot easier to take your car to a trusted auto repair shop. Our advice is to always ask them to explain in detail what exactly is wrong and then verify the symptoms. You should also check with a different shop to get a second opinion.

Torque Converter Replacement Cost

The torque converter is not going to be cheap to replace. Genuine OEM (Original Equipment Manufacturer) products cost at least $800, with some cars costing up to $2,000 just for the converter. Labor is usually another $425 ($85 per hour, at least five hours to replace it), so you’re looking at a potential repair cost of around $1,225.

One way to reduce the cost is to get a remanufactured torque converter instead. A remanufactured component is a secondhand part that’s usually been salvaged from a junk car. The part is rebuilt and machined to meet the manufacturer’s specifications as close as possible.

So, you’re not getting a new OEM product, but it’s almost as good as new. And they typically cost between $150 and $350. Overall, you should prepare at least between $600 and $1,000 for a new torque converter—if you’re getting a remanufactured one.

While it still sounds expensive, that’s nothing compared to rebuilding or replacing an entire transmission. Transmission rebuilds or replacements are at least $1,500 unless you get a junk transmission. And most cars will cost around $2,500 to rebuild the transmission. So, always verify whether you have a transmission or torque converter issue.

Can I Replace It Myself?

Most of us normal people won’t be able to replace it ourselves. Even if you regularly change the oil and replace the spark plugs yourself, replacing a torque converter is not going to be a breeze. This process takes at least five hours to finish, and a DIY job can take up to 10 hours.

The process entails disconnecting the car’s driveshaft and then removing the transmission’s bell housing from the car. Only after removing the transmission bell housing will you then be able to remove the old torque converter and replace it with a new one. Afterward, you’ll have to reinstall it all back and make sure you did the job properly.

The video above illustrates how to replace the torque converter, but it doesn’t show the long and arduous process of removing the transmission from the car. While it will save quite a lot of money, it’s just better to leave it to a professional. Save yourself some time, and save yourself from the trouble and stress of replacing it yourself.

What If The Cost Is Too Much?

If your car is under five years old, check if the warranty is still valid. Most new cars come with a powertrain warranty that includes the torque converter. If it’s still valid, you’ll be able to replace it for a lot cheaper or at no cost at all depending on their policy. Some carmakers such as Hyundai even offer a 10-year powertrain warranty for their cars.

If the warranty is no longer valid, consider doing a transmission fluid change first. This process removes all the old transmission fluid and replaces it with a new one. Transmission fluid changes are necessary, usually between 60,000 and 100,000 miles in automatic cars. This is typical of your regular Ford transmission fluid change.

If you haven’t had a fluid change in a while, replacing the fluid may solve your problem. This costs about $250 on average for most cars. However, if your transmission fluid is in good condition, this probably won’t help. Even if it does, there’s no guarantee it will solve your problems.

If you have no other choice but to replace the torque converter and you can’t afford it, consider selling your car as-is or scrapping it (especially if you know how to sell a car privately). Selling your car as-is means you’ll have to sell it at a lower price, usually deducting your car’s average value on the market with the repair costs.

It’s like you’re still paying for the repairs anyway, but this at least puts cash in your hand. And considering secondhand car prices at an all-time high (at the time of writing), it might not be such a bad idea. We recommend doing this if the repair cost isn’t far off from your car’s secondhand value.

Torque Converter FAQ

Got any more questions about torque converters? The answer you’re looking for might be down here:

What Does A Torque Converter Do

A torque converter has two purposes: multiplying the amount of torque from the engine to the transmission, so there’s a very minimal loss of power. And to connect and disconnect the transmission from the engine, just like a clutch in a manual transmission. When it connects, the torque converter is what allows the car to creep forward.

How Does A Torque Converter Work

A torque converter works by using a pump/impeller that constantly spins with the engine’s flywheel and crankshaft. This pumps the transmission fluid onto a turbine, which then pumps that fluid into a stator that multiplies the torque and increases the fluid’s flow rate. The fluid then flows back onto the pump, increasing the pump’s rotation, and ultimately the turbine as well. As the turbine spins, it spins the transmission’s shaft which powers the transmission, and ultimately, the car’s wheels. It also has a lock-up clutch that prevents the turbine from spinning when the car is in the Neutral gear.

What Does A Stall Converter Do

A high stall converter or sometimes referred to as just a “stall converter” is a type of aftermarket torque converter that stalls at a higher RPM when you floor the gas pedal and hold the brakes at the same time. Most stock cars stall at around 1,500rpm, while a high stall converter can sometimes go up to 3,000rpm. The purpose is so that you can load the engine at a higher RPM before letting go of the brakes. So by the time you let go of it, the engine is closer to the power band and launches much faster. Unnecessary unless you’re building a drag racer with an automatic transmission.

What Causes A Torque Converter To Fail

Just like any moving part in a car, the torque converter will fail due to wear and tear. Or sometimes it’s one of the solenoids (an electrically-controlled valve) that fails. In any case, most torque converters last for about 100,000 miles, although some owners report that theirs have lasted up to 200,000 miles. Proper maintenance and careful driving will help the torque converter to last longer.

How To Test A Torque Converter

Testing a torque converter is usually done with a stall test. This test requires you to put the transmission in Drive and then flooring the gas pedal while holding the brakes. This will cause the engine to stall, and if it stalls below the specification, then the torque converter is faulty. For example, if the manufacturer specifies it should stall at 2,000rpm and yours stall at 1,500rpm, then the torque converter is faulty. Note that not every car can do this test, and even if it can, there’s a risk you damage the entire powertrain. Don’t do a stall test for more than 5 seconds at a time.

What Is A Torque Converter Clutch

A torque converter clutch is known as a lock-up clutch. This clutch locks the turbine and prevents it from spinning when you’re not in Drive, preventing the car from moving.

Final Thoughts

That’s pretty much everything that you need to know about the torque converter in your automatic car. One thing we haven’t mentioned is how to maintain your torque converter to ensure that it lasts as long as possible.

It doesn’t actually require any maintenance, apart from changing the transmission fluid every 60,000 miles or whenever it’s dirty. Aside from that, just make sure you drive with a little bit of sympathy for your car.

Also, try not to tow any heavy loads when you don’t need to, as this increases stress on the entire transmission assembly. If you need to tow, then always make sure the load doesn’t exceed your car’s tow rating.

Whether you need a torque converter repair, or you just want to expand your car knowledge, hopefully, this article has been helpful for you.