- How to Diagnose a Faulty Car Bearing

- Benefits of Upgrading Your Car Bearings

- Causes of Premature Bearing Failure

- Different Types of Car Bearings

- Properly Maintain Your Car Bearings

- Wheel Hub Bearings for Cars

- Tips for Choosing the Right Replacement

- Role of Seals in Protecting Your Bearings

- Grease-Lubricated vs Oil-Lubricated Bearings

- How to Tell When It’s Time to Replace

How to Diagnose a Faulty Car Bearing

Diagnosing a faulty car bearing can be a difficult task, as the symptoms of a bad bearing may not be immediately apparent. However, some tell-tale signs can help you identify if your car has an issue with its bearings.

- The first sign of a faulty bearing is usually an unusual noise coming from the wheel area. This noise will usually sound like grinding or squealing and will become louder when turning corners or accelerating. If you hear this type of noise, it is important to have your vehicle inspected by a qualified mechanic as soon as possible to determine if the issue is related to the bearings.

- Another symptom of bad bearings is increased vibration in the steering wheel or pedals when driving at higher speeds. This vibration could indicate that one or more of your car’s bearings are worn out and need replacing.

- Finally, if you notice any changes in how your vehicle handles while driving, such as difficulty turning corners or increased resistance when braking, these could also be signs that something is wrong with one or more of your car’s bearings. So, it’s wise to diagnose both the front wheel bearing and the rear wheel bearing, among other potential faults.

If any of these symptoms are present in your vehicle it is important to have it inspected by a qualified mechanic who can diagnose and repair any issues with its bearings before they cause further damage to other components in the system.

The Benefits of Upgrading Your Car Bearings

Upgrading your car bearings can provide several benefits for your vehicle. Bearings are essential components in the operation of any vehicle, and upgrading them can help to improve performance, reduce wear and tear, and extend the life of your car. Here are some of the key advantages that come with upgrading your car bearings:

- Improved Performance: Upgrading to higher quality bearings can help to improve overall performance by reducing friction between moving parts. This reduces drag on the engine, allowing it to run more efficiently and providing better acceleration. Additionally, upgraded bearings will be able to handle higher loads without wearing out as quickly as lower-quality ones.

- Reduced Wear & Tear: High-quality bearings are designed with superior materials that resist wear and tear better than standard ones. This means they will last longer before needing replacement or repair, saving you money in the long run on maintenance costs. Additionally, upgraded bearings will also reduce vibration which can cause damage over time if left unchecked.

- Extended Life Span: By reducing friction between moving parts and resisting wear & tear better than standard components, upgraded car bearings can extend the life span of your vehicle significantly compared to using stock parts alone. This means you’ll get more miles out of each bearing before needing a replacement or repair job done on them – saving you money in both short-term maintenance costs as well as long-term repairs down the line.

Upgrading your car’s bearing is an easy way to ensure optimal performance while extending its lifespan at minimal cost (not to mention, the cost of a replacement wheel bearing) – making it an excellent investment for any driver looking for improved reliability from their vehicle over time.

Common Causes of Premature Bearing Failure in Cars

Premature bearing failure in cars is a common problem that can lead to costly repairs and even complete engine failure. Bearing failure can be caused by a variety of factors, including improper installation, inadequate lubrication, contamination, and excessive loads. Understanding the causes of premature bearing failure can help car owners take steps to prevent it from occurring.

- Improper installation is one of the most common causes of premature bearing failure in cars. If bearings are not installed correctly or with the correct tools, they may not be properly aligned or seated within their housing. This can cause them to wear prematurely or fail due to misalignment and vibration.

- Inadequate lubrication is another common cause of premature bearing failure in cars. Bearings require regular lubrication to function properly and reduce friction between moving parts. If bearings are not adequately lubricated they will wear out faster than normal due to increased friction and heat buildup which can lead to catastrophic damage if left unchecked for too long.

- Contamination is another factor that can lead to premature bearing failure in cars as dirt, dust, water or other contaminants may enter the system through seals or other openings causing damage over time as they accumulate on surfaces within the system leading to increased friction between components which will eventually cause them to fail prematurely if left unchecked for too long.

- Excessive loads placed on bearings during operation may also contribute towards their early demise as these components are designed only for certain levels of load capacity beyond which they will start wearing out faster than normal leading eventually towards complete breakdown if left unchecked for too long without proper maintenance being carried out regularly on them.

The Different Types of Car Bearings and Their Uses

Car bearings are essential components of a vehicle’s drivetrain, providing support and allowing for the smooth rotation of the wheels. There are several different types of car bearings, each with its purpose and function. Understanding the different types of car bearings and their uses can help you make informed decisions when it comes to maintaining your vehicle.

- The most common type of car bearing is a ball bearing, which consists of two metal rings with small steel balls in between them. These bearings are used in wheel hubs to reduce friction between moving parts and allow for smoother rotation. Ball bearings can also be found in transmissions, alternators, power steering pumps, and other automotive components that require precise movement or alignment.

- Tapered roller bearings are another type of car bearing that is commonly used in wheel hubs as well as transmissions and other drivetrain components. These bearings consist of two tapered inner rings with rollers between them that provide support while allowing for smooth rotation at high speeds. Tapered roller bearings are designed to handle higher loads than ball bearings due to their larger contact area between the inner rings and rollers.

- Needle roller bearings are similar to tapered roller bearings but have smaller rollers that provide less friction while still providing adequate support for rotating parts at high speeds. Needle roller bearings can be found in wheel hubs as well as transmissions, power steering pumps, alternators, water pumps, fuel injectors, camshafts, crankshafts, and other automotive components requiring precise movement or alignment at high speeds or under heavy loads.

- Thrust ball/roller/needle/taper-roller-bearings all serve a similar purpose: they provide axial support while allowing for smooth rotation at high speeds or under heavy loads without excessive friction or wear on the parts involved in the process (e.g., transmission gears). Thrust ball/roller/needle/taper-roller-bearings can be found in manual transmissions as well as automatic ones; they’re also used on driveshafts connecting engines to wheelsets on vehicles such as cars and trucks alike.

Finally, there is an angular contact ball bearing which is typically used when there is an angle present between two rotating shafts such as those found on differential assemblies where one shaft rotates faster than another due to gear ratios within the assembly itself. Angular contact ball bearing helps reduce frictional losses by providing an even distribution load across both shafts thus reducing wear over time.

How to Properly Maintain Your Car Bearings

Properly maintaining your car bearings is essential for ensuring the longevity and performance of your vehicle. Bearings are an integral part of a car’s suspension system, allowing the wheels to rotate freely and smoothly. Without proper maintenance, bearings can become worn or damaged, leading to costly repairs or even complete failure of the suspension system. Here are some tips for properly maintaining your car bearings:

1. Check Your Bearings Regularly: It is important to inspect your car’s bearings regularly for signs of wear or damage. Look for any cracks in the bearing housing, as well as any discoloration or rusting that may indicate water has entered the bearing area. If you notice any issues with your bearings, it is best to have them replaced immediately by a qualified mechanic.

2. Clean Your Bearings: Dirt and debris can accumulate on your car’s bearings over time, causing them to wear out prematurely and reducing their performance capabilities. To keep them clean and functioning properly, use a soft brush or cloth to remove dirt from around the bearing area before lubricating it with oil or grease as needed.

3. Lubricate Your Bearings: Proper lubrication is essential for keeping your car’s bearings in good condition and preventing premature wear-and-tear from occurring due to friction between moving parts within the suspension system. Use only high-quality lubricants specifically designed for automotive applications when lubricating your vehicle’s bearings; this will help ensure optimal performance while also protecting against corrosion caused by moisture buildup over time due to exposure from road conditions such as rainwater splashing up onto components underneath the vehicle bodywork during driving conditions such as heavy rainstorms etc.

4. Replace Worn-Out Parts: If you notice that any parts associated with your vehicle’s suspension system are worn out (such as bushings), they must be replaced immediately to prevent further damage from occurring due to excessive friction between moving parts within this assembly which could lead not only too costly repairs but also potentially dangerous situations if left unchecked/unrepaired.

By following these simple steps regularly you can ensure that all components associated with your vehicle’s suspension system remain in good working order so that you can enjoy safe driving experiences without worrying about potential breakdowns caused by faulty/worn-out parts.

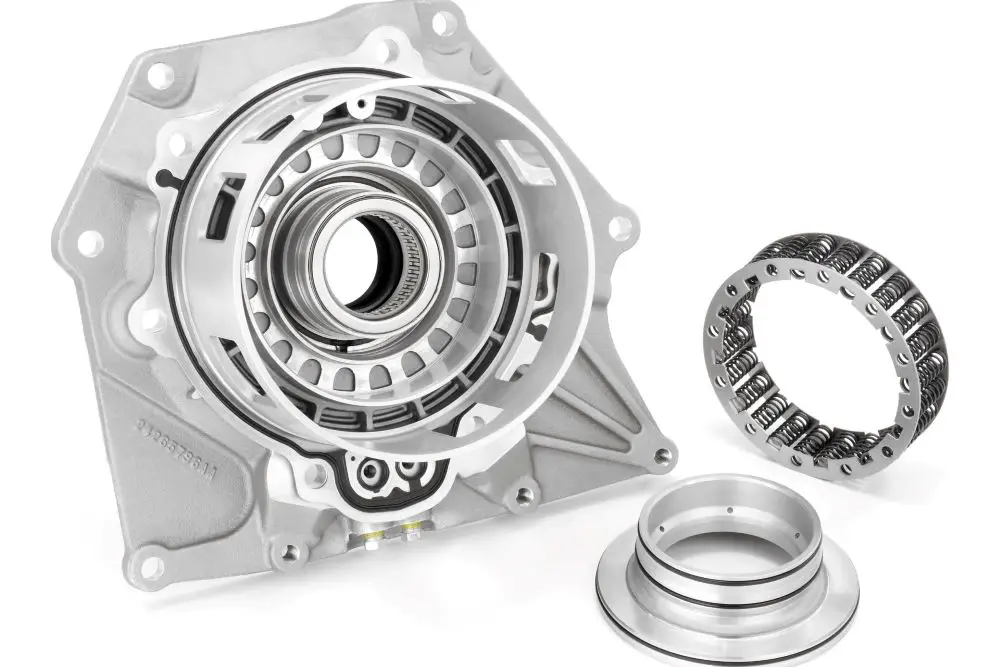

What You Need to Know About Wheel Hub Bearings for Cars

Wheel hub bearings are an important component of a car’s suspension system. They are responsible for providing support to the wheel and allowing it to rotate freely. Without them, the wheels would not be able to turn properly, leading to poor handling and increased wear on other parts of the vehicle. To learn more, check out our guide on how many wheel bearings does a car have.

- Wheel hub bearings are typically made from steel or aluminum and consist of two main components: an inner race and an outer race. The inner race is mounted onto the wheel hub assembly while the outer race is connected to the wheel itself. Between these two components is a set of rolling elements such as balls or rollers that allow for smooth rotation when force is applied.

- For a wheel hub bearing to function properly, it must be properly lubricated with grease or oil at all times. This helps reduce friction between moving parts and prevents premature wear on both components. It also helps keep dirt and debris out of the bearing which can cause damage over time if left unchecked.

- When replacing a wheel hub bearing, you must use one that’s designed specifically for your make and model vehicle as different vehicles require different sizes and types of bearings to function correctly. Additionally, you should always follow manufacturer instructions when installing new bearings as improper installation can lead to premature failure or even catastrophic damage in some cases.

Finally, regular maintenance should be performed on your car’s wheel hubs to ensure they remain in good working condition at all times; this includes checking for any signs of wear or damage such as cracks or loose bolts/nuts which could indicate that replacement may be necessary soon.

Tips for Choosing the Right Replacement Car Bearing

When it comes to replacing car bearings, it is important to choose the right one for your vehicle. Here are some tips to help you make the best decision:

1. Determine the type of bearing you need: There are several types of bearings available, including ball bearings, roller bearings, and tapered roller bearings. Make sure you know which type is compatible with your vehicle before making a purchase.

2. Consider the size and load capacity: The size and load capacity of a bearing will determine how well it performs in your car. Make sure that the bearing you choose can handle the weight and stress that will be placed on it while driving.

3. Check for compatibility with other parts: Before purchasing a replacement bearing, make sure that it is compatible with other parts in your car such as brakes or suspension components. This will ensure that everything works together properly when installed in your vehicle.

4. Look for quality materials: When selecting a replacement bearing, look for one made from high-quality materials such as steel or aluminum alloy so that it can withstand wear and tear over time without breaking down prematurely or becoming damaged easily due to heat or vibration from driving conditions on roads or highways.

5. Research brands: Different brands offer different levels of quality when it comes to their products so do some research into which ones have good reviews from customers who have used them before making a purchase decision.

Understanding the Role of Seals in Protecting Your Vehicle’s Bearings

Seals play an important role in protecting the bearings of your vehicle. Bearings are essential components of any vehicle, as they allow for smooth and efficient operation. Without proper protection, these bearings can become damaged or worn out over time, leading to costly repairs and even complete failure of the vehicle.

- Seals provide a barrier between the bearing and its environment, helping to keep dirt, dust, moisture, and other contaminants away from the bearing surface. This helps to extend the life of your bearings by preventing premature wear or damage caused by environmental factors.

- When selecting seals for your vehicle’s bearings, it is important to consider several factors such as size, material type, and operating temperature range. The size should be appropriate for the application; too small a seal will not provide adequate protection while too large a seal may cause excessive friction or binding in some applications.

- The material type should also be chosen carefully; some materials are better suited for certain environments than others due to their resistance to heat or chemicals that may be present in those environments.

- Finally, it is important to select seals with an operating temperature range that is suitable for your application; if temperatures exceed what is recommended by the manufacturer then this could lead to premature failure of the seal itself or even damage to other components within your system due to excessive heat buildup.

- In addition to selecting appropriate seals for your application, it is also important that they are installed correctly; incorrect installation can lead not only to reduced performance but also potential damage due to improper sealing pressure being applied on sensitive components such as bearings or shafts which could result in premature wear or failure over time.

- It is therefore recommended that you consult with a qualified technician when installing new seals on any part of your vehicle’s system so that you can ensure optimal performance and longevity from all components involved in its operation.

By understanding how seals work and taking into account all relevant factors when selecting them for use on your vehicle’s system you can help ensure optimal performance from all parts involved while extending their lifespan significantly through proper protection against environmental contaminants such as dirt, dust, and moisture which could otherwise cause premature wear or damage over time if left unchecked.

The Pros and Cons of Grease-Lubricated vs Oil-Lubricated Car Bearings

When it comes to car bearings, there are two main types of lubrication: grease-lubricated and oil-lubricated. Each type has its advantages and disadvantages, so it is important to understand the differences between them to make an informed decision when selecting a bearing for your vehicle.

- The primary advantage of grease-lubricated bearings is that they require less frequent maintenance than oil-lubricated bearings. Grease lubrication provides a thick layer of protection against wear and tear, which means that the bearing can last longer without needing to be replaced or serviced. Additionally, grease lubrication helps reduce friction between moving parts, resulting in smoother operation and improved performance.

- On the other hand, oil-lubricated bearings offer superior protection against corrosion due to their ability to penetrate tight spaces where grease cannot reach. This makes them ideal for use in wet or humid environments where rusting can be an issue with other types of lubricants. Furthermore, oil-based lubricants tend to have higher viscosity ratings than greases which allows them to better withstand high temperatures and pressures without breaking down as quickly as greases do.

In conclusion, both grease-lubricated and oil-lubricated car bearings have their unique advantages and disadvantages depending on the application they are being used for. Grease offers superior wear protection while oils provide better corrosion resistance; however, both types require regular maintenance for them to remain effective over time. Ultimately it is up to you as the consumer to decide which type best suits your needs based on your specific requirements and environmental conditions.

How to Tell When It’s Time to Replace Your Vehicle’s Wheel Hub Bearing

When it comes to vehicle maintenance, one of the most important components to keep an eye on is the wheel hub bearing. This part helps keep your wheels in place and ensures a smooth ride. Over time, however, it can become worn out or damaged due to normal wear and tear.

Knowing when it’s time to replace your vehicle’s wheel hub bearing is essential for keeping your car running safely and efficiently.

- The first sign that you may need a new wheel hub bearing is if you hear a grinding wheel bearing noise coming from the wheels when driving. This noise could indicate that the bearings are worn out or damaged and need replacing. Additionally, if you feel vibrations coming from the steering wheel while driving, this could also be an indication that something is wrong with your wheel hub bearing.

- Another way to tell if it’s time for a new wheel hub bearing is by checking for any signs of leaking oil around the area where the bearings are located. If there are any signs of oil leakage, then this could mean that there is damage to either one or both of them which will require replacement for them to function properly again.

- Finally, if you notice any unusual wear patterns on your tires such as uneven treading or bald spots on certain areas then this could also be an indication that something isn’t right with your vehicle’s wheel hub bearings and they should be inspected by a professional mechanic as soon as possible to determine whether they need replacing or not.

Replacing a worn-out or damaged wheel hub bearing can help ensure the safe operation of your vehicle while also improving its performance overall so it pays off in the long run.