- How Precious Metals Impact the Cost

- What Factors Influence Precious Metal Prices

- Benefits of Investing in Precious Metals

- Different Types of Precious Metals Used

- Relationship Between Emissions and Precious Metals

- Analyzing Trends in Markets for Precious Metals

- Impact of Recycling on Precious Metal Prices

- Different Types of Refining Processes

- Technologies That Could Reduce Dependence

- Exploring Modern Potential Alternatives

How Precious Metal Prices Impact the Cost of Catalytic Converters

The cost of catalytic converters is largely determined by the prices of precious metals, such as platinum, palladium, and rhodium. These metals are used in the production of catalytic converters and their prices can fluctuate significantly over time. Hence, the need to stay updated with the catalytic converter precious metal prices.

As a result, changes in the price of these metals can have a significant impact on the cost of catalytic converters. When precious metal prices increase, so does the cost to produce catalytic converters. This is because manufacturers must pay more for these materials when their prices rise.

As a result, they must pass this additional cost onto consumers to remain profitable. On the other hand, when precious metal prices decrease, manufacturers can reduce their costs and pass those savings on to consumers in the form of lower-priced products.

It is important to note that fluctuations in precious metal prices can be unpredictable and sudden. This means that it can be difficult for manufacturers to accurately predict how much they will need to charge for their products at any given time due to changing market conditions.

Therefore, it is important for consumers to stay informed about current trends to make sure they are getting a good deal on their purchases when shopping for catalytic converters or other products containing these materials. This is why catalytic converters are so valuable.

What Factors Influence Precious Metal Prices in Catalytic Converters?

Precious metal prices in catalytic converters are influenced by a variety of factors, including the global supply and demand for metals, economic conditions, geopolitical events, and environmental regulations. Here are what typically impacts the catalytic converter precious metal prices:

- The global supply and demand for metals are one of the most important factors that influence precious metal prices in catalytic converters. When there is an increase in demand for a particular metal, its price will rise accordingly. On the other hand, when there is an oversupply of a certain metal on the market, its price will decrease.

- Economic conditions also play an important role in determining precious metal prices in catalytic converters. When economic growth is strong and consumer spending increases, it can lead to higher demand for metals used in catalytic converters which can drive up their prices.

- Conversely, when economic growth slows down or consumer spending decreases due to recessionary pressures or other factors such as high unemployment rates or rising inflation rates then this can lead to lower demand for these metals which could result in lower prices.

- Geopolitical events such as wars or political unrest can also have an impact on precious metal prices in catalytic converters as they may cause disruptions to the production and transportation of these materials which could affect their availability on the market and thus their pricing structure.

- Additionally, changes to environmental regulations may also affect precious metal prices as stricter regulations may require more expensive materials that are not readily available on the market leading to higher costs associated with them which would be reflected through increased pricing structures for these materials used within catalytic converters.

The Benefits of Investing in Precious Metals Used in Catalytic Converters

Investing in precious metals used in catalytic converters can be a lucrative endeavor for those looking to diversify their portfolios. Precious metals such as platinum, palladium, and rhodium are essential components of catalytic converters, which are used to reduce harmful emissions from vehicles.

As the demand for these metals increases due to stricter environmental regulations, so too does their value (and the catalytic converter precious metal prices). Here are some of the benefits of investing in precious metals used in catalytic converters:

1. Stability: Precious metal prices tend to remain relatively stable over time compared to other investments such as stocks and bonds. This makes them an attractive option for investors who want a low-risk investment with potential long-term returns.

2. Diversification: Investing in precious metals provides portfolio diversification since they do not move with the stock market or other traditional investments like bonds and mutual funds. This means that if one type of investment is performing poorly, your portfolio will still have some stability due to your holdings in precious metals used in catalytic converters.

3. Tax Benefits: Investing in certain types of precious metal coins may provide tax benefits depending on where you live and how you structure your investments. For example, many countries offer tax incentives for investing in gold coins or bullion bars that meet certain criteria set by the government or central bank authority responsible for regulating currency exchange rates and transactions within its borders.

4. Liquidity: Precious metal coins can be easily converted into cash when needed, making them a liquid asset. This means that investors can quickly access their money without having to wait weeks or months before being able to sell off their holdings.

Overall, investing in precious metals used in catalytic converters is an attractive option for those looking for stability, diversification, tax benefits, and liquidity. With careful research into current market conditions and trends, investors can make informed decisions about when it is best to buy or sell these valuable assets.

Understanding the Different Types of Precious Metals Used in Catalytic Converters

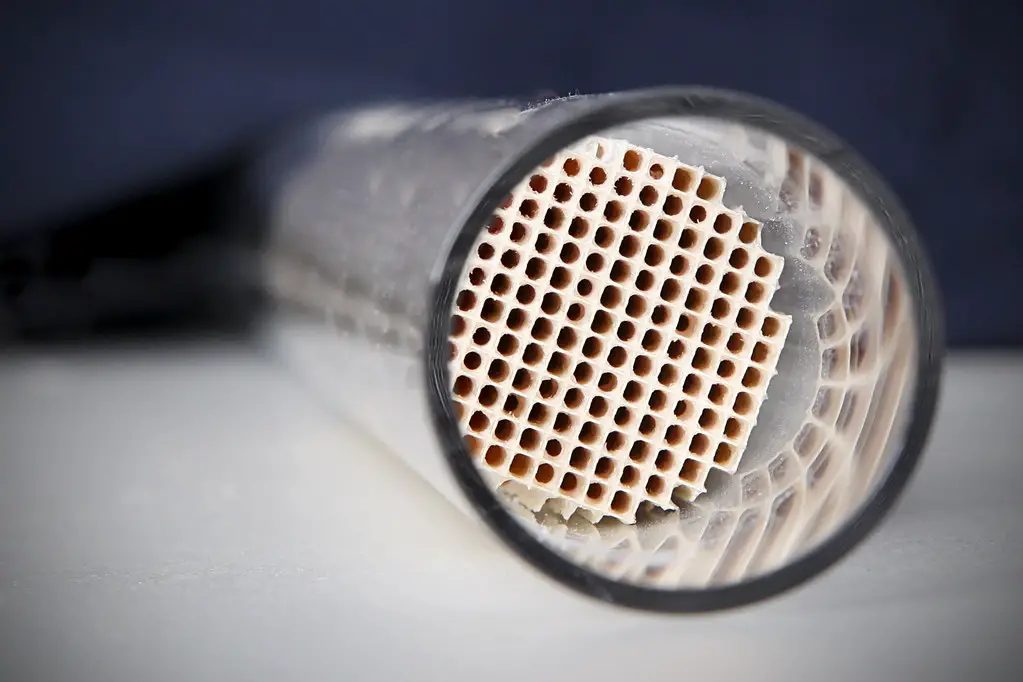

Catalytic converters are an important part of modern vehicle exhaust systems, as they help reduce the number of harmful pollutants released into the atmosphere. These devices rely on a variety of precious metals to function properly, and understanding the different types can be beneficial for those looking to purchase or maintain a catalytic converter.

- The most common type of precious metal used in catalytic converters is platinum. Platinum is highly resistant to corrosion and oxidation, making it ideal for use in high-temperature environments such as those found in vehicle exhaust systems. It also has excellent catalytic properties, meaning it can effectively convert harmful pollutants into less toxic compounds. To learn more, check out our guide on how much platinum is in a catalytic converter.

- Another type of precious metal used in catalytic converters is palladium. Palladium has similar properties to platinum but is generally more affordable and easier to obtain. It also has excellent thermal stability and can withstand higher temperatures than other metals without degrading or corroding over time.

- Rhodium is another type of precious metal used in catalytic converters that offer superior performance compared to other metals due to its high melting point and resistance to corrosion and oxidation at elevated temperatures. Rhodium also has excellent electrical conductivity, making it ideal for use with electronic components such as oxygen sensors that are often found within these devices. For more insight, check out our explainers on which catalytic converters have the most rhodium.

- Finally, gold is sometimes used as a catalyst material due to its ability to form strong bonds with other elements such as carbon monoxide (CO) which helps reduce emissions from vehicles equipped with these devices even further than what would be possible using only platinum or palladium alone. Gold’s low reactivity makes it an ideal choice for this application since it will not degrade over time like some other materials might when exposed to high temperatures or corrosive gases present within vehicle exhaust systems.

In conclusion, there are several different types of precious metals that can be used in catalytic converters depending on their intended purpose and desired performance characteristics; however, platinum remains the most popular choice due to its superior durability and effectiveness at reducing emissions from vehicles equipped with these devices.

Exploring the Relationship Between Automotive Emissions and Precious Metal Prices for Catalytic Converters

The automotive industry is a major contributor to air pollution, and catalytic converters are an important component of modern vehicles that help reduce emissions. Catalytic converters contain precious metals such as platinum, palladium, and rhodium that act as catalysts to convert harmful pollutants into less harmful substances.

As the demand for these metals increases due to the growing number of vehicles on the road, their prices have also risen significantly in recent years. This article will explore the relationship between automotive emissions and precious metal prices for catalytic converters.

Catalytic converters are essential components of modern cars that help reduce emissions by converting pollutants into less harmful substances before they enter the atmosphere. The process requires a catalyst made from one or more precious metals such as platinum, palladium, and rhodium.

These metals are expensive due to their rarity and limited supply; therefore, when demand increases due to increased vehicle production or stricter emission standards, their prices tend to rise accordingly. This can also impact other variables, such as what vehicles have the most valuable catalytic converters.

The relationship between automotive emissions and precious metal prices can be seen in several ways: firstly, increased vehicle production leads to higher demand for these metals which drives up their price; secondly, stricter emission standards require more efficient catalysts which means more expensive materials must be used; thirdly, rising fuel costs can lead consumers towards purchasing more fuel-efficient cars which require higher quality catalysts with higher concentrations of these rare metals; finally, government regulations may also affect the price of these materials by imposing taxes or other restrictions on them.

In conclusion, there is a clear link between automotive emissions and precious metal prices for catalytic converters: increased vehicle production leads to higher demand for these rare materials which drives up their cost; stricter emission standards require better quality materials with higher concentrations of rare elements; rising fuel costs encourage consumers towards buying more efficient cars with better quality components; finally government regulations may also affect pricing through taxes or other restrictions imposed on them.

Analyzing Trends in Global Markets for Precious Metals Used in Catalytic Converters

“Catalytic Converter” by Hiddenpower is licensed under CC BY-NC-SA 2.0

The global market for precious metals used in catalytic converters is an ever-evolving one. As the demand for cleaner air increases, so does the need for these metals to help reduce emissions from vehicles. In recent years, there have been several trends that have emerged in this market that are worth noting.

- First, the demand for palladium has grown significantly due to its ability to reduce emissions of nitrogen oxides and hydrocarbons from gasoline engines. This has led to a sharp increase in prices over the past few years as supply struggles to keep up with demand.

- Second, platinum is also becoming increasingly popular as a catalyst metal due to its ability to reduce carbon monoxide and hydrocarbon emissions from diesel engines. This trend has been further bolstered by stricter regulations on diesel engine emissions across many countries around the world.

- Third, rhodium is gaining traction as a catalyst metal due to its superior performance when it comes to reducing nitrogen oxide emissions from gasoline engines compared with other metals such as palladium and platinum. This trend is likely driven by increasing environmental concerns about air pollution caused by vehicle exhausts around the world.

- Finally, gold is being used more frequently in catalytic converters due to its low cost and high durability compared with other precious metals such as palladium or platinum. Gold’s use in catalytic converters can help reduce costs while still providing effective emission-reduction performance over time.

Overall, these trends demonstrate how quickly global markets can change when it comes to precious metals used in catalytic converters and how important it is for companies involved in this industry to stay abreast of developments so they can remain competitive and profitable in the future.

Examining the Impact of Recycling on Precious Metal Prices for Catalytic Converter Components

Recycling has become an increasingly important part of our society, and its impact on the environment is undeniable. One area where recycling can have a significant effect is in the prices of precious metals used in catalytic converter components. This article will examine how recycling affects the prices of these metals and what this means for consumers.

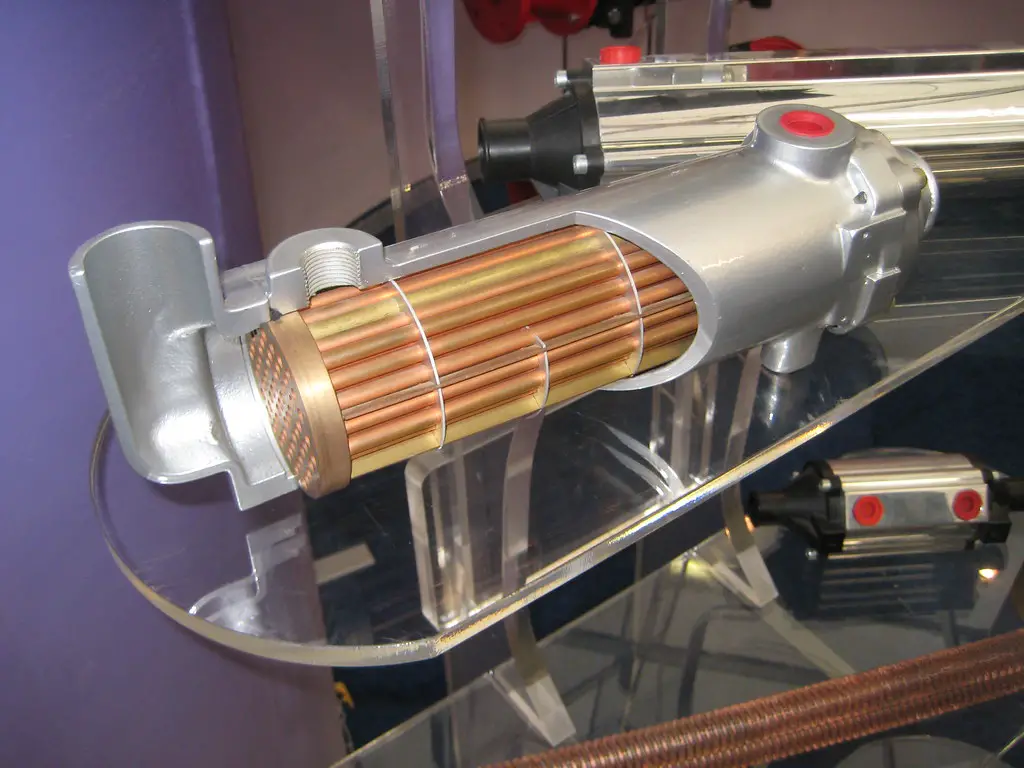

Catalytic converters are an essential component of modern vehicles, as they help reduce emissions from exhaust systems. These converters contain several different types of precious metals, including palladium, platinum, and rhodium.

The price of these metals (and thus, the high price of a catalytic converter) can fluctuate significantly depending on supply and demand factors such as mining production levels or new vehicle sales trends. Recycling plays a major role in determining the price of these precious metals used in catalytic converters.

When more recycled materials are available to be reused in manufacturing processes, it reduces demand for newly mined materials which helps keep prices lower than they would otherwise be if only new materials were available for use.

Additionally, when more recycled materials are available to be reused it also increases competition among manufacturers which further helps to keep prices low by creating downward pressure on them due to increased competition among suppliers for contracts with automakers or other customers who need catalytic converter components made from these precious metals.

The impact that recycling has on the price of these precious metal components is significant and should not be overlooked when considering how much money consumers may save when purchasing a new vehicle or replacing their existing one’s catalytic converter components with newer ones made from recycled material instead of newly mined material that may cost more due to higher demand for it at any given time period due to limited availability caused by mining production levels being lower than desired or needed at any given time period.

In conclusion, recycling plays an important role in keeping costs down for consumers who need replacement parts containing precious metal components such as those found inside catalytic converters used in vehicles today.

By increasing competition among suppliers through increased availability of recycled material that can be reused instead of relying solely on newly mined material which may cost more due to higher demand at any given time period, recycling helps ensure that consumers get access to quality parts at reasonable prices while also helping protect our environment by reducing waste associated with mining operations.

Comparing Different Types of Refining Processes for Extracting Valuable Metals from Scrap Catalysts

Refining processes for extracting valuable metals from scrap catalysts are essential for the recycling of these materials. There are several different types of refining processes available, each with its own advantages and disadvantages (thus, impacting the catalytic converter precious metal prices).

This article will compare and contrast the various methods to help readers understand which process is best suited to their needs.

- The first type of refining process is hydrometallurgical extraction. This method involves using a combination of chemical reagents and physical separation techniques to extract metals from scrap catalysts. The advantage of this method is that it can be used on a wide variety of materials, including those containing high levels of impurities or contaminants. Additionally, it can be used in both batch and continuous operations, making it suitable for large-scale production runs. However, this process requires specialized equipment and expertise to achieve optimal results, making it more expensive than other methods.

- The second type of refining process is pyrometallurgical extraction. This method uses heat to separate metals from scrap catalysts by melting them down into liquid form before they are separated out into individual components through cooling or condensation techniques. The advantage here is that pyrometallurgical extraction can be used on a wide range of materials without requiring any additional processing steps such as chemical reagents or physical separation techniques like hydrometallurgy does; however, this method also requires specialized equipment and expertise to achieve optimal results which makes it more expensive than other methods as well as potentially hazardous due to the use of high temperatures involved in the process itself.

- Finally, electrochemical extraction is another type of refining process that can be used for extracting valuable metals from scrap catalysts but has some distinct advantages over both hydrometallurgy and pyrometallurgy when compared side-by-side with them: firstly, electrochemical extraction does not require any additional processing steps such as chemical reagents or physical separation techniques; secondly, this method does not involve any hazardous high temperatures like pyrometallurgy does; thirdly, electrochemical extraction has been proven effective at recovering even trace amounts (less than 1%)of precious metals from scrap catalysts; finally – unlike both hydrometallurgy and pyrometallurgy – electrochemical extraction requires minimal specialized equipment which makes it much less expensive than either one when compared side-by-side with them overall.

In conclusion, all three types have their own unique advantages depending on what kind of material you’re working with, how much metal you need to be extracted, how quickly you need your results, etc. Hydrometallurgical Extraction offers versatility while Pyrometallurgical Extraction offers speed.

Electrochemical Extraction offers cost-effectiveness while still being able to recover trace amounts. Ultimately, each situation will require careful consideration before deciding which option best suits your needs. This should all come to play when you’re accounting for the catalytic converter replacement cost.

New Technologies That Could Reduce Dependence on Precious Metals for Emissions Control Systems

The automotive industry is increasingly looking for ways to reduce its dependence on precious metals for emissions control systems. Precious metals, such as platinum, palladium, and rhodium, are used in catalytic converters to reduce harmful exhaust emissions from vehicles.

However, these materials are expensive and their availability is limited. As a result, the automotive industry is exploring new technologies that could potentially replace or supplement the use of precious metals in emissions control systems.

- One promising technology being investigated is the use of nanomaterials in catalytic converters. Nanomaterials are extremely small particles that can be engineered to have specific properties and functions. In this case, nanomaterials could be designed with catalytic properties similar to those of precious metals but at a much lower cost and with greater availability than traditional materials. Additionally, nanomaterials may offer improved performance compared to traditional materials due to their increased surface area-to-volume ratio which allows them to more effectively convert pollutants into harmless gases such as carbon dioxide and water vapor.

- Another technology being explored is the use of fuel additives that can help reduce harmful exhaust emissions without relying on precious metals or other expensive materials. These additives work by altering the chemical composition of fuel so that it burns more efficiently and produces fewer pollutants when combusted in an engine’s cylinders. This approach is effective at reducing nitrogen oxide (NOx) levels by up to 50%, making it an attractive option for automakers looking for ways to reduce their reliance on costly materials while still meeting stringent emission standards set by regulatory bodies around the world.

- Finally, researchers are also investigating alternative methods for controlling exhaust emissions without relying on any type of material at all – namely through advanced engine designs that minimize pollutant production during combustion cycles through improved air/fuel mixing techniques or other modifications aimed at optimizing efficiency while minimizing waste products produced during operation. While these approaches may not completely eliminate the need for some type of material-based solution (such as a catalyst), they could potentially provide significant reductions in overall costs associated with meeting emission standards while still providing acceptable levels of performance from engines equipped with them.

In conclusion, there are several promising technologies currently being investigated which could potentially reduce dependence on precious metals for automotive emissions control systems. By utilizing nanomaterials, fuel additives, or advanced engine designs, automakers may be able to find cost-effective solutions which allow them to meet stringent environmental regulations without having to rely heavily upon costly resources like platinum, palladium, or rhodium.

Exploring Potential Alternatives to Traditional Platinum-Based Catalyst Systems

The use of platinum-based catalysts has been a mainstay in the chemical industry for decades. However, due to their high cost and limited availability, there is an increasing need to explore alternative catalyst systems that can provide similar performance at a lower cost. This article will discuss some potential alternatives to traditional platinum-based catalyst systems.

- One potential alternative is palladium-based catalysts. Palladium is much less expensive than platinum and can be used in many of the same applications as its more expensive counterpart. In addition, palladium has been shown to have higher activity than platinum in certain reactions, making it an attractive option for those looking for improved performance at a lower cost.

- Another option is ruthenium-based catalysts. Ruthenium is also less expensive than platinum and has been found to be effective in many of the same reactions as its more costly counterpart. Additionally, ruthenium has been found to be more active than both palladium and platinum in certain reactions, making it an attractive choice for those seeking improved performance at a lower cost point (and the catalytic converter precious metal prices).

- Finally, cobalt-based catalysts are another potential alternative worth considering when exploring options outside of traditional platinum-based catalyst systems. Cobalt is significantly cheaper than both palladium and ruthenium but still provides good activity levels in many reactions where other metals may not perform as well or may not even be viable options due to their high costs or limited availability on the market today.

In conclusion, there are several potential alternatives available when exploring options outside of traditional platinum-based catalyst systems that offer comparable performance at a fraction of the price point associated with their more costly counterparts such as palladium-, ruthenium-, and cobalt-based catalysts which all offer good activity levels while providing significant savings over using pure Platinum based solutions alone.