- What Affects the Lifespan of an Alternator?

- How to Tell When Your Alternator Needs Replacing

- Benefits of Regular Maintenance for Alternators

- Signs That Your Alternator Is Failing

- How to Extend the Life of an Alternator

- Pros and Cons of Rebuilt vs New Alternators

- Causes of Premature Alternator Failure

- Diagnose a Faulty or Failing Alternator

- Tips for Choosing the Right Replacement

- Cost Implications of Replacing an Old Alternator

What Factors Affect the Lifespan of an Alternator?

The lifespan of an alternator is determined by a variety of factors, including the quality of the alternator, the type of vehicle it is installed in, and how well it is maintained.

- Quality: The quality of an alternator can have a significant impact on its lifespan. Alternators that are made with higher-quality materials and components tend to last longer than those made with lower-quality parts. Additionally, some manufacturers offer extended warranties on their products which can help to ensure that your alternator will last for many years.

- Vehicle Type: The type of vehicle in which an alternator is installed can also affect its lifespan. Alternators used in larger vehicles such as trucks or SUVs may be subject to more wear and tear due to their increased weight and size compared to smaller cars or sedans. As such, these types of vehicles may require more frequent maintenance or replacement than smaller cars do.

- Maintenance: Proper maintenance is essential for ensuring that your alternator lasts as long as possible. Regularly checking the fluid levels and inspecting belts for signs of wear can help prevent problems before they occur and extend the life expectancy of your alternator significantly. Additionally, replacing worn-out parts promptly will help keep your system running smoothly for many years to come.

How to Tell When Your Alternator Needs Replacing

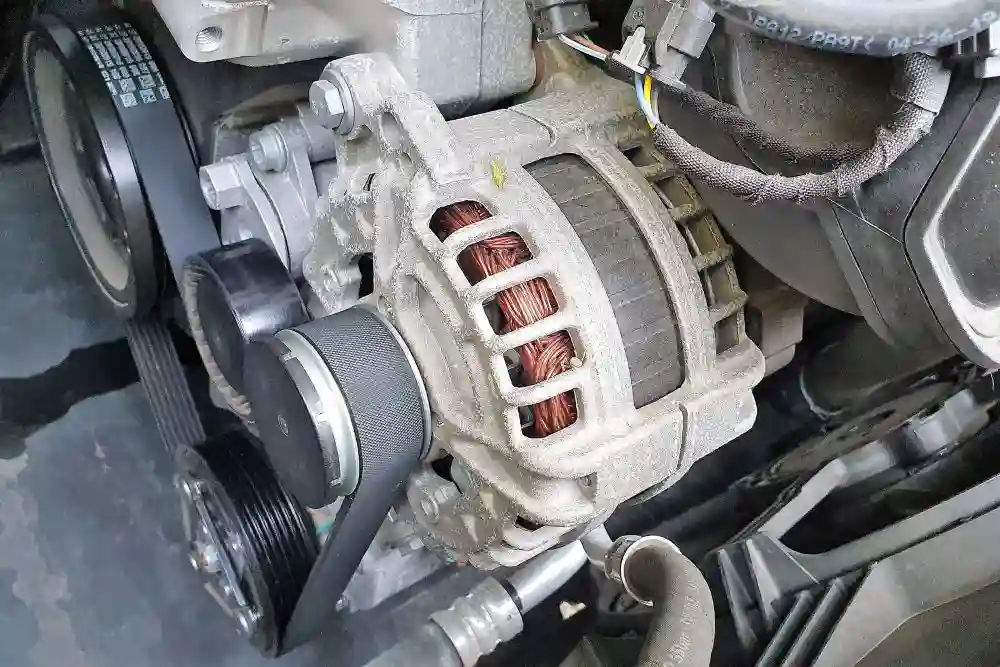

Your car’s alternator is an essential component of its electrical system, and it is responsible for keeping the battery charged and powering all of the vehicle’s electrical components. If your alternator fails, your car will not be able to start or run properly.

Therefore, it is important to recognize when your alternator needs replacing so that you can take action before a complete breakdown occurs. If you’d like to figure out how it all works, check our our 3 wire alternator wiring diagram.

- Several signs indicate an alternator may need replacing. One of the most common signs is dimming headlights or interior lights while driving. This could be caused by a failing alternator as it struggles to keep up with the demand for power from these components. Additionally, if you notice any strange noises coming from under the hood such as grinding or squealing sounds, this could also indicate a problem with your alternator belt or pulley system which should be checked out immediately by a professional mechanic.

- Another sign that indicates an issue with your alternator is if you experience difficulty starting your vehicle after turning off the ignition switch; this could mean that there isn’t enough power being generated by the battery due to a faulty alternator not charging it correctly. Finally, if you notice any warning lights on your dashboard such as “battery” or “check engine” lights illuminated then this could also point towards an issue with your car’s electrical system which should be investigated further by a qualified technician who can diagnose and repair any problems quickly and efficiently before they become more serious issues down the line.

If you suspect that there may be something wrong with your car’s alternator then it is important to have it checked out right away to avoid further damage and costly repairs in the future; only qualified mechanics should carry out repairs on complex automotive systems like these so make sure you take yours into a reputable garage for diagnosis and repair work whenever necessary.

The Benefits of Regular Maintenance for Alternators

Regular maintenance of alternators is essential for ensuring that they remain in good working condition and continue to provide reliable power. Alternators are responsible for converting mechanical energy into electrical energy, which is then used to power a variety of devices and systems.

Without regular maintenance, alternators can become damaged or malfunction, leading to costly repairs or even complete replacement. For more insight, check out our write-up on the average alternator repair cost.

- The most important benefit of regular maintenance for alternators is improved performance. Regularly checking the voltage output and inspecting the brushes, bearings, and other components can help identify any potential problems before they become serious issues. This allows technicians to make necessary repairs or adjustments before the alternator fails. Additionally, regularly cleaning the exterior of an alternator helps keep it free from dirt and debris that could interfere with its operation.

- Regular maintenance also helps extend the life of an alternator by preventing wear and tear on its components over time. By regularly inspecting all parts for signs of damage or wear, technicians can replace worn parts before they cause further damage to other components in the system. This not only prevents costly repairs but also ensures that your system remains reliable over time without needing frequent replacements due to premature failure caused by lack of care and attention.

- Finally, regular maintenance helps reduce energy costs associated with running an alternator system by ensuring that it runs efficiently at all times. By keeping all components clean and properly lubricated as well as replacing worn parts when necessary, you can ensure that your system runs at peak efficiency without wasting excess energy unnecessarily due to poor performance caused by neglecting routine maintenance tasks such as cleaning filters or replacing worn brushes regularly.

In conclusion, regular maintenance for alternators is essential to ensure their continued reliability, performance, longevity, and cost-effectiveness. Taking proper care of your system will help you avoid costly repairs down the line while also helping you save money on energy costs associated with running an inefficiently maintained system.

Common Signs That Your Alternator Is Failing

1. Dimming or Flickering Lights: One of the most common signs that your alternator is failing is dimming or flickering lights. This can be caused by a decrease in voltage output from the alternator, which can cause the lights to flicker or dim when you turn on other electrical components such as air conditioning, headlights, and wipers.

2. Dead Battery: If your battery is dead and won’t hold a charge, it could be due to a faulty alternator. The alternator helps keep the battery charged while you are driving so if it isn’t working properly then your battery will eventually die out.

3. Warning Light: Many cars have an indicator light on their dashboard that will come on when there is an issue with the charging system of your car including problems with the alternator. If this light comes on then it’s time to get your car checked out by a mechanic as soon as possible before any further damage occurs to other parts of your vehicle such as the battery or starter motor.

4. Strange Noises: A failing alternator can make strange noises such as whining, grinding, or squealing sounds coming from under the hood of your car which could indicate that something isn’t quite right with its internal components and needs attention immediately before further damage occurs to other parts of your vehicle like belts and hoses, etc.

5. Slow Engine Crank: If you notice that it takes longer than usual for your engine to crank up when starting then this could be another sign that something isn’t quite right with either the starter motor or more likely –the alternator itself–as both are responsible for providing power to start up an engine successfully each time you turn over its ignition key.

How to Extend the Life of an Alternator

The alternator is an essential component of a vehicle’s electrical system, providing power to the battery and other electrical components. It is important to maintain your alternator to ensure that it continues to function properly and extend its life. Here are some tips for extending the life of an alternator:

1. Check the Alternator Belt: The belt that connects the alternator to the engine should be checked regularly for signs of wear or damage. If it is worn or cracked, it should be replaced immediately as this can cause damage to both the belt and the alternator itself.

2. Keep Your Battery Charged: A weak or dead battery can put extra strain on your alternator, causing it to work harder than necessary and potentially leading to premature failure. Make sure you keep your battery charged by regularly checking its voltage level with a voltmeter and charging it if necessary.

3. Monitor Electrical Loads: Excessive electrical loads can also put extra strain on your alternator, so make sure you monitor any additional electrical components such as lights, audio systems, etc., that may be drawing power from your vehicle’s system. If possible, try not to exceed 80% of the maximum load capacity when using these components to reduce stress on your alternator over time.

4. Have Regular Maintenance Checks: Having regular maintenance checks performed by a qualified mechanic will help ensure that any potential problems with your vehicle’s electrical system are identified early before they become more serious issues down the line which could lead to costly repairs or replacements later on down the road.

By following these simple steps you can help extend the life of your vehicle’s alternator and avoid costly repairs in future years.

The Pros and Cons of Rebuilt vs New Alternators

When it comes to replacing an alternator, there are two main options: rebuilt or new. Each option has its advantages and disadvantages, so it is important to consider both before making a decision.

- The primary advantage of a rebuilt alternator is cost. Rebuilt alternators are typically much less expensive than new ones, making them an attractive option for those on a budget. Additionally, they often come with warranties that can provide peace of mind in the event of any problems down the road.

- On the other hand, there are some drawbacks to choosing a rebuilt alternator over a new one. For starters, rebuilt alternators may not be as reliable as their brand-new counterparts due to their age and wear and tear from previous use. Furthermore, they may not have all the latest features and technology that newer models offer which could lead to reduced performance or efficiency over time.

- Ultimately, when deciding between buying a rebuilt or new alternator for your vehicle it is important to weigh all factors carefully before making your decision. Consider your budget and how long you plan on keeping your car to determine which option best suits your needs and lifestyle.

What Are the Most Common Causes of Premature Alternator Failure?

Premature alternator failure is a common problem that can be caused by a variety of factors. The most common causes of premature alternator failure include:

1. Overheating: Alternators are designed to operate within a certain temperature range, and when they become too hot, they can fail prematurely. This is often caused by inadequate cooling or ventilation, or an overworked engine.

2. Loose Connections: If the connections between the alternator and other components are loose or corroded, it can cause an electrical short circuit which will lead to premature failure of the alternator.

3. Poor Maintenance: Regular maintenance is essential for keeping your vehicle in good condition and preventing premature alternator failure. This includes checking belts for wear and tear, replacing worn parts such as brushes and bearings, and ensuring that all connections are clean and secure.

4. Faulty Parts: Faulty parts such as brushes or bearings can cause excessive wear on the internal components of the alternator which will lead to its eventual breakdown if not replaced in time.

5. Overcharging Battery: If your battery is being overcharged due to a faulty regulator or incorrect settings on your charging system then this could also lead to premature alternator failure due to excessive strain on its internal components.

How to Diagnose a Faulty or Failing Alternator

The alternator is an essential component of a vehicle’s electrical system, as it is responsible for generating the power needed to keep the battery charged and all of the vehicle’s electrical systems running. If you’d like to learn more about how it works, check out our one wire alternator wiring diagram for Chevy vehicles.

A faulty or failing alternator can cause a variety of symptoms that can range from minor inconveniences to major issues that can leave your car inoperable. It is important to diagnose a faulty or failing alternator as soon as possible to prevent further damage and ensure your safety on the road.

- The first symptom of a faulty or failing alternator is often dimming headlights or interior lights. This occurs when the battery does not have enough power to keep up with demand, which indicates that it may not be receiving enough charge from the alternator. Other signs include difficulty starting, flickering gauges, dead battery, illuminated check engine light, and strange noises coming from under the hood such as whining or grinding sounds.

- If you suspect that your alternator may be having issues, there are several tests you can perform to diagnose it properly. The first test involves checking for voltage output at idle speed; this should be between 13-14 volts with no load on the system (i.e., no accessories turned on). If this voltage reading is lower than expected then it could indicate an issue with either your battery or your alternator itself.

- Another test involves checking for current draw; this should remain constant even when accessories are turned on and off while driving (such as air conditioning). If there is any fluctuation in a current draw then this could indicate an issue with either your battery or your alternator itself. Finally, you should also check for any visible signs of damage such as corrosion around connection points which could indicate an issue with wiring harnesses connected to either component (battery/alternator).

In conclusion, diagnosing a faulty or failing alternator requires careful observation and testing to determine if there are any underlying issues causing problems within its components (battery/alternators) which need attention before further damage occurs and leaves you stranded on the side of the road without power.

Tips for Choosing the Right Replacement Alternator for Your Vehicle

When it comes to replacing the alternator in your vehicle, it is important to choose the right one for your specific make and model. Here are some tips to help you select the best replacement alternator for your vehicle:

1. Check Your Vehicle’s Specifications: Before purchasing a new alternator, make sure you know the exact specifications of your vehicle. This includes its year, make model, and engine size. Knowing this information will help you find an alternator that is compatible with your car or truck.

2. Consider Your Alternator’s Amperage Rating: The amperage rating of an alternator indicates how much power it can produce at a given time. Make sure that the amperage rating of the new alternator matches or exceeds that of your old one so that it can provide enough power for all of your car’s electrical components.

3. Look For Quality Parts: When selecting a replacement part for any component in your vehicle, always look for quality parts from reputable manufacturers or suppliers who offer warranties on their products and services. This will ensure that you get a reliable part that will last longer and perform better than the cheaper alternatives available on the market today.

4. Compare Prices: Once you have narrowed down which type of replacement part is best suited for your needs, compare prices from different retailers to get the best deal possible on an OEM-quality product at an affordable price point.

5. Get Professional Installation: Finally, if possible, have a professional mechanic install any new parts to ensure proper installation and avoid potential problems down the road.

Understanding the Cost Implications of Replacing an Old or Worn-Out Alternator

Replacing an old or worn-out alternator can be a costly endeavor. It is important to understand the cost implications of such a replacement before deciding to do so.

- The cost of replacing an alternator will depend on several factors, including the make and model of your vehicle, as well as the type and quality of parts used in the alternator repair. Generally speaking, labor costs for replacing an alternator can range from $50-$200 depending on where you take your vehicle for service. The cost of parts will vary depending on what type and quality you choose; however, it is typically between $100-$400.

- In addition to labor and parts costs (remember to account for the alternator replacement labor cost), there may also be additional fees associated with replacing an alternator such as taxes or disposal fees for old parts. It is important to ask about any additional fees when getting a quote from a mechanic or auto shop so that you are aware of all potential costs associated with the repair before committing to it.

- Finally, it is important to consider any warranties that may come with new parts when deciding whether or not to replace your old alternator. Many manufacturers offer warranties on their products which can help offset some of the cost if something goes wrong after installation. Be sure to ask about any available warranties when getting quotes from mechanics or auto shops so that you are aware of all potential benefits associated with purchasing new parts for your vehicle’s repair job.

In conclusion, understanding all potential costs associated with replacing an old or worn-out alternator is essential before making this decision for your vehicle’s repair job. Labor costs typically range from $50-$200 while part prices vary depending on the type and quality chosen; however, there may also be additional fees such as taxes or disposal charges which should be taken into consideration when budgeting for this repair job.

Additionally, many manufacturers offer warranties on their products which could help offset some expenses if something goes wrong after installation; therefore it is important to inquire about these benefits when getting quotes from mechanics or auto shops before committing to this repair job.