Have you gotten a check engine light and a code P0325 or a different code that indicates a problem with the knock sensor on your car? And you want to do a knock sensor replacement? Well, if that is the case, then you are at the right place because there will be a lot to cover on this topic.

- Knock Sensor?

- Function

- Diagram

- Location

- OBD2 Codes

- Symptoms

- Diagnosis

- Replacement

- Cost

- Conclusion

- F.A.Q

Having a problem like this can be a really frustrating thing to deal with because nobody wants to deal with the check engine light and similar problems because they can be a real pain to get sorted out.

Nowadays cars are all packed with tech and there are many things that can break down. Sensors, solenoids, you name it. All these components have electrical circuits and sometimes after long use they can break down and cause a ton of issues like in our case with the knock sensor.

This is why you need to get a diagnostics tool also known as an OBD2 scanner and a multimeter in order to get these things sorted out quickly and effectively. But you shouldn’t worry because we are going to help you out.

First, we are going to learn what is a knock sensor and what is the knock sensor function. Then we will learn the locations, the OBD2 codes, and the symptoms that you will experience with this component. After that, we will learn more about diagnostics and the knock sensor replacement. So, if you want to learn more, follow along.

What Is A Knock Sensor?

Now before we learn more about the symptoms and the knock sensor replacement, let’s first focus more on the basics and learn what this sensor is all about. I bet that there are a ton of people reading this article who are not that into cars and want to learn the basics.

So, these chapters are dedicated to them. If you feel like you are up to the task, you can move on to the next chapters where we are going to cover more on the symptoms and other topics such as the knock sensor replacement. If not, keep up with us for a bit.

Nevertheless, a knock sensor is a special sensor that is mounted on the engine block. This sensor is basically screwed into the block on one side and then connected to the harness and the computer from the other side.

Cars with inline engines have one knock sensor. But cars with two banks like a V6 or a V8 usually have two of these sensors. One sensor per bank of the engine.

So, whenever you get a code for example P0332 that indicates bank 2, this means that the sensor where cylinder number 2 is located has some trouble working. And to find this cylinder you need to check the owner’s manual or some online sources. Since bank 1 and bank 2 are not the same in every carmaker.

Once we cleared out the basics of this sensor, we can move on to the function and learn more about the knock sensor function. In other words, what does this sensor do in the first place? And that we are going to cover in the next chapter.

Knock Sensor Function

Now as we learned more about the knock sensor and how many of these sensors are there, let’s now focus on the knock sensor function. What is the function of this component on your car?

This sensor in essence is a microphone. A fine-tuned microphone that is designed to work on specific frequencies and collect the data needed.

More precisely, this sensor is there to notice when there is abnormal combustion inside of the engine cylinder which is known as engine knock.

This sound if not diagnosed on time could create damage inside of your engine and possibly scrap it altogether. This is why carmakers wanted to sort out this problem and help you prevent engine damage and pay less money on repair bills.

These sounds are very frequently caused by low-grade fuel. For example, if you use low octane fuel instead of premium gas if your car was designed to use premium. Other causes are bad engine timing, lean air to fuel mixture, worn-out timing belt tensioners, or worn-out timing belts or timing chains. But how does this sensor works behind the curtain?

Well, this sensor collects the sounds that are present in the crankcase and then sends this data to the PCM. Then the PCM decides what to do, either to add more fuel inside of the combustion and adjust the air to fuel ratio or retard the engine timing.

By doing these adjustments, you can be sure that your engine will be safe and you will not need to perform an expensive repair on your car. But before we learn more about knock sensor replacement, let’s take a look at the diagram first.

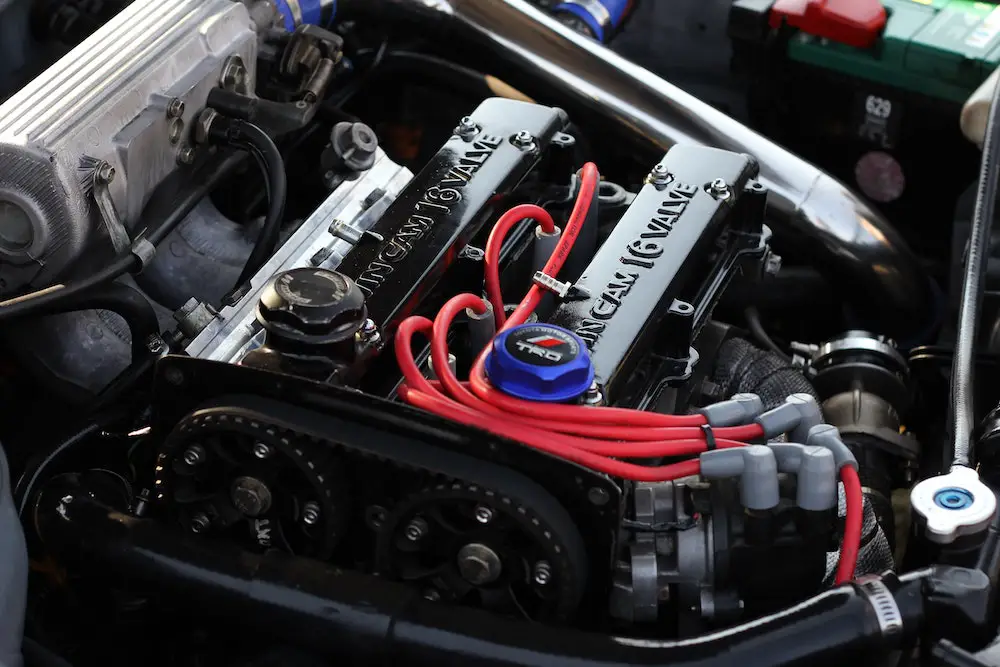

Knock Sensor Diagram

Now as we covered how this sensor works behind the curtain, now before we learn more about the knock sensor replacement, let’s discuss more about the diagram. As you probably know, every electrical component has a diagram.

Reading diagrams is a really essential thing to do when it comes to diagnosing electrical issues in your car. Namely, because these diagrams tell you where to look. This knock sensor diagram is simply a map to know where to look in order to solve your problem and diagnose the sensor.

But unfortunately, we cannot draw, so we are going to simply explain the diagram briefly so you get the perspective of what is going on inside of this sensor.

On the inside of this sensor, there is a piezoelectric ring that is in charge of doing all the complex measurements of the noises. Remember that this device works only on a specific frequency and it is really delicate.

When it comes to the connections, there are two types of sensors. A single wire and two-wire sensors.

A single wire sensor is a sensor that only has one wire, which is the 5-volt signal wire from the PCM and the body of the sensor is the ground contact.

While on the other hand in newer cars there are two-wire sensors. One ground wire and one signal wire with the same 5 volt signal from the PCM.

Overall, it cannot be simpler than this when it comes to diagnostics. Later on in the article, before we cover the knock sensor replacement we are going to learn how you can diagnose it the right way.

Knock Sensor Location

Now before we dive into the knock sensor replacement, let’s first cover another topic. Which is the knock sensor location. If you want to replace this sensor you need to learn where it is located. This is why we are going to help you out.

As we mentioned in the previous chapters, there could be one or two of these sensors on your engine. Some engines that have the cylinders in an inline order have one of these sensors.

While other engines that have a V configuration, have two of these sensors. But where they are mounted on?

Well, they are mounted on the block itself. Old sensors that are single wire sensors usually screw on the block from the side. While more modern ones have a ring shape, and then you put a bolt in it and screw it onto the engine block.

It really depends much on the carmaker that is producing the car where they will put these devices so the exact location really depends. Sometimes it is on the side of the block underneath the exhaust manifolds while sometimes it is in the center of the engine valley on some V8 engines.

This is why we recommend you to go online and learn more about your specific engine plus the phrase “knock sensor location”. This way you will get the best results. There are a ton of images out there that will give you good and valuable information. Now let’s move to something else before we cover the knock sensor replacement.

Knock Sensor OBD2 Codes

Now let’s discuss more about the OBD2 codes that you might get when you are dealing with this type of sensor. This is another important piece of information to know before you start understanding how to diagnose this problem and perform a knock sensor replacement. So, what are the codes that are mostly associated with this component?

Well, if you have only one knock sensor on your car, three codes are the most common occurrence. These codes are P0324, P0325, P0327, P0328, and P0239 for bank 1. And P0330, P0331, P0332, P0333, P0334, and P0335 for bank 2 if you are running a V8 engine.

All of these codes indicate different problems concerned with this sensor. They might indicate a general circuit malfunction, or problems with the voltage like high input, or low input in the circuit. Or in some cases range circuit codes.

This type of code will be present if your sensor is completely dead and is not producing a signal in the right range from 0 to 5 volts like in our case. Resulting in a range code. More about this we are going to elaborate on later before we dive into the knock sensor replacement. But for now, let’s cover the knock sensor symptoms.

Knock Sensor Symptoms

Now as we covered the basics of the knock sensor and we learned what this component is all about. We think that now it is time to dive deeper and start uncovering all of the symptoms that this sensor produces.

Especially when it comes to this sensor, you will be able to tell right of the bat that it is causing the problem if you know them. This is why we are going to cover all of the knock sensor symptoms in depth before we dive into the knock sensor replacement.

1. Check Engine Light

The first in our list of symptoms that indicate a need for a knock sensor replacement is the check engine light.

This check engine light is one of the most frequent symptoms that many drivers will notice. And is a good symptom, to be honest.

Mainly because many drivers will not be able to tell if the knock sensor is faulty without this light. So, whenever the check engine light turns on, there are codes as we all know. And in order for you to investigate these codes, you need a special tool that is known as an OBD2 scanner tool.

With this tool, you will get access to the PCM and you will be able to tell what could be causing the issue. There are a number of codes and we have covered all of them in one of the previous chapters. Still, the most common one is the P0325.

So, whenever you get a check engine light, get a scanner and scan the car for codes. If you determine some codes concerning this sensor, diagnose it and perform a knock sensor replacement. More on this we are going to cover later on in the article.

2. Engine Starts To Knock

The second most common symptom that could indicate a need for a knock sensor replacement is the knocking sound that will be present in the engine.

As we already explained previously. The knock sensor is basically a small microphone that can detect sounds at a specific frequency.

Whenever this sensor is not working right, there will be no information to the PCM about knocks inside of the engine and be able to prevent them. So, consequently, your engine will knock more than it did before.

The PCM will not be able to retard the camshaft timing or adjust the air to fuel ratio and the engine will work under these conditions. And this could also lead to possible engine damage. So, you need to perform a knock sensor replacement once you notice how the engine starts knocking.

3. Poor Engine Performance

The next symptom that could indicate a need for knock sensor replacement is poor engine performance.

Whenever this knock sensor is out of service, the engine computer will not be able to adjust the engine timing and the air to fuel ratio.

So, consequently, you will face a lot of troubles down the alley. The engine will run really bad in some instances. There will be vibrations and also the combustion process would be rather bad.

Some instances of this type of work will be the engine misfires. When a knock sensor is broken the engine will love to misfire. The timing will be off and there will be premature or delayed combustion. You will notice these knocks from the engine and pops from the exhaust pipe.

Also, rough engine idle is one of these symptoms of poor engine work. The engine will idle really poorly. The RPM will fluctuate and you will have a hard time driving this vehicle. So, you should be aware of these issues as well.

So, whenever you are dealing with this problem is important for you to address the issue and perform a knock sensor replacement as soon as possible.

4. Poor Fuel Economy

And the last symptom that we are going to cover that can indicate a need for a knock sensor replacement is the poor fuel economy.

We explained that this sensor is helping the PCM to adjust the air to fuel ratio on your vehicle. So, you can imagine what will happen when this sensor will not give this information to the PCM.

So, the computer will not be able to adjust the ratio and this will result in poor fuel economy on your car. The numbers will drop quite significantly in some more extreme cases. You shouldn’t be confused if you have a drop of 5 MPG or even more in your fuel economy.

That’s why whenever you experience engine knocks, check engine light, or poor fuel economy, you need to investigate this problem deeper and determine what is causing it. And that’s what we are going to cover in the next chapter before we learn more about the knock sensor replacement.

How To Diagnose A Knock Sensor?

Now before we discuss the knock sensor replacement. Let’s first take a look at how you can diagnose this sensor on your car. How you will be able to tell if it’s good or bad?

Well, it’s actually quite simple. Let’s say that you have diagnosed a code on the car. The next thing you need to do is to locate the specific sensor on your vehicle since some cars have two of these sensors.

Once you have located the sensor, the next thing will be to remove it from the car. Single wire sensors usually are bolt-on. While two-wire sensors usually have a bolt that goes through them. The second type is the most common in modern cars.

Once you removed the sensor you can jump to diagnosing this component. Just get a multimeter and tweak it to DC voltage.

Then attach alligator clips on both of the pins. If the sensor is good it should show close to zero or zero volts. Then tap this sensor slightly with a hammer, and the voltage should jump. And the stronger you tap the sensor, the higher the voltage will be.

This is a good sensor if the voltage is moving up and down based on the input that you give it. If there is no voltage or the voltage is abnormally high it means that the circuit is out of range and you have a bad sensor. So, in this case, you need a knock sensor replacement. And more on that next.

Knock Sensor Replacement

So, how you can perform a knock sensor replacement? Well, this process is actually fairly simple. The first thing that you need to learn is where this sensor is located.

It is usually located on one side of the engine block if it’s an inline engine. Or if it’s a V8, you have two of these sensors. One per each side.

Once you located the sensor, the next thing is to remove it. For this, you will need a socket wrench. Then unbolt the bolt that is holding it and then unplug the connector. Repeat the procedure with the new sensor and you will be good to go.

Knock Sensor Replacement Cost

The average cost to replace this sensor is between $50 and $250. It will cost you $50 to $100 if you replace the part by yourself.

If you decide to go to a shop, you can expect to pay somewhere between $140 to $250 depending on the make and model of vehicle that you have.

Conclusion

In this article, we have covered quite a bit when it comes to the knock sensor replacement. We learned what this component is and why it is important. We learned the diagram, location, and OBD2 codes that are associated with it.

Then we learned the symptoms, the diagnosis process, and the costs involved in replacing this unit on your vehicle.

F.A.Q

Now let’s answer some frequently asked questions.

What Is A Knock Sensor

A knock sensor is a special sensor that is installed on the engine block. This sensor is there to listen for abnormal work inside of the engine. This means that this sensor is basically a microphone that records sounds on a specific frequency. Then tells the PCM to adjust the camshaft position or the air to fuel ratio to improve the combustion.

What Does A Knock Sensor Do

The knock sensor has the simple role to listen for abnormal knocking inside of the engine. Then the PCM once collects this data, will adjust the engine work in order to solve the knocking situation inside of the block. Either by adjusting the air to fuel mixture or retarding the position of the camshaft.

What Causes A Knock Sensor To Go Bad

This is really unknown what is causing the sensor to go bad. A ton of mechanics will say that this is caused by misuse. But in most cases, this is mainly caused by age or internal damage to the sensor’s circuit.

How To Test A Knock Sensor

You can test this sensor with a multimeter. And it is really easy to do. Remove the sensor and get a multimeter. Place one probe on one contact and the other on the second contact. Then give the sensor some taps. A good sensor will read from 0 to 5 volts depending on how strong you tap it.

How Much Is A Knock Sensor Replacement

A knock sensor replacement is about $140 to $250 on average. This cost is if you do this job at a shop. If you decide to replace the sensor at home, you will pay less than $100 in most cases.

Can I Drive With A Bad Knock Sensor

Yes, you can drive with a bad knock sensor. Driving with a sensor like this is possible. But not recommended. Since the PCM will not be able to adjust the work of your engine, the engine will knock a lot more and cause engine damage.