- What is a Crankshaft Position Sensor?

- Symptoms of a Faulty Crankshaft Position Sensor

- Diagnose and Replace a Crankshaft Position Sensor

- Aftermarket Crankshaft Position Sensor

- Types of Crankshaft Position Sensors

- Troubleshooting Tips for Common Issues

- Malfunctioning Crankshaft Position Sensor

- Smartphone-Enabled Diagnostics

- Comparing OEM vs Aftermarket Replacement Parts

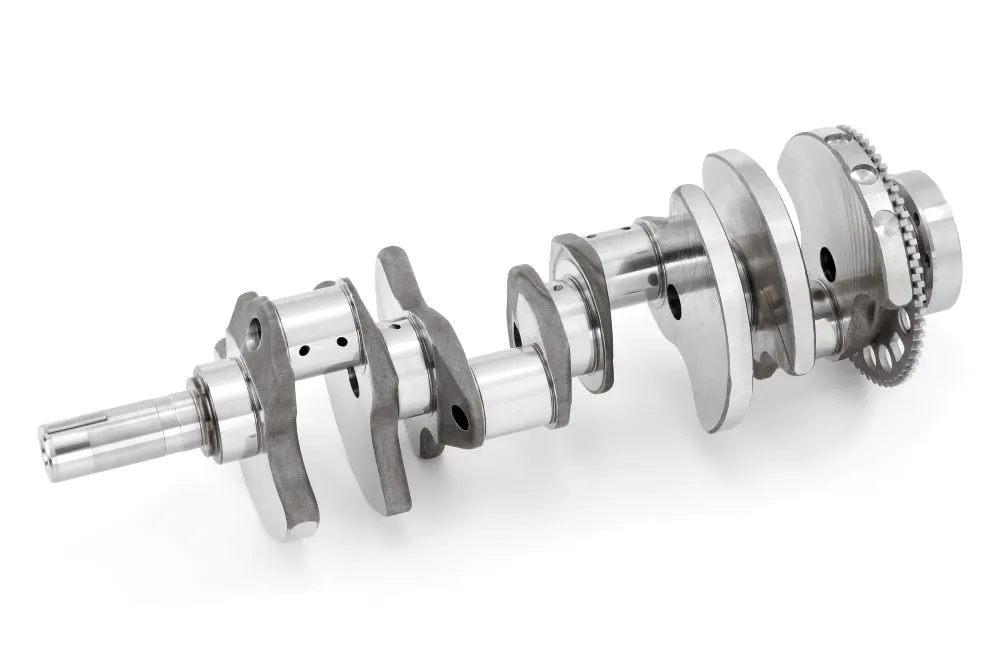

What is a Crankshaft Position Sensor and How Does it Work?

A crankshaft position sensor is a device used to monitor the rotational speed and position of the crankshaft in an internal combustion engine. It is typically located near the crankshaft, either at the front or rear of the engine.

The sensor works by detecting changes in the rotational speed and position of the crankshaft as it turns. This information is then sent to an electronic control unit (ECU) which uses it to adjust fuel injection timing, ignition timing, and other engine parameters for optimal performance.

The sensor itself consists of two main components: a magnetic pickup coil and a Hall effect switch. The magnetic pickup coil detects changes in magnetic field strength as it passes over magnets embedded in the flywheel or harmonic balancer attached to the end of the crankshaft.

As these magnets pass by, they induce a voltage signal in the coil which is then sent to an ECU for processing. The Hall effect switch detects changes in voltage levels as it passes over notches cut into either side of each magnet on its way around its rotation path; this information is also sent to an ECU for processing.

By combining data from both components, an ECU can accurately determine when each cylinder should fire during each revolution of its four-stroke cycle (intake stroke, compression stroke, power stroke, and exhaust stroke). This allows for precise control over fuel injection timing and ignition timing which helps ensure optimal performance from your vehicle’s engine at all times.

Common Symptoms of a Faulty Crankshaft Position Sensor

A crankshaft position sensor is an important component of a vehicle’s engine. It monitors the position and speed of the crankshaft and sends data to the engine control unit (ECU). When this sensor malfunctions, it can cause a variety of symptoms that may affect the performance of your vehicle. Common symptoms of a bad crankshaft position sensor include:

1. Engine misfires: A malfunctioning crankshaft position sensor can cause intermittent or random misfires, which can lead to poor acceleration and reduced fuel efficiency.

2. Stalling: If your car stalls unexpectedly while driving, it could be due to a faulty crankshaft position sensor sending incorrect information to the ECU about engine speed and timing.

3. Check Engine Light: The check engine light will often illuminate when there is an issue with the crankshaft position sensor or other components in your vehicle’s ignition system.

4. Rough idling: A malfunctioning crankshaft position sensor can cause rough idling as well as stalling when coming to a stop or slowing down for turns in traffic.

5. Poor acceleration: If you experience difficulty accelerating, it could be due to incorrect information being sent from the crankshaft position sensor about engine speed and timing which affects how much power is delivered by your car’s engine during acceleration

How to Diagnose and Replace a Crankshaft Position Sensor

The crankshaft position sensor is an important component of a vehicle’s engine. It monitors the position and speed of the crankshaft and sends this information to the engine control unit (ECU). If it fails, it can cause a variety of problems, including poor fuel economy, misfiring, stalling, or even no-start conditions.

Fortunately, diagnosing and replacing a faulty crankshaft position sensor is relatively straightforward.

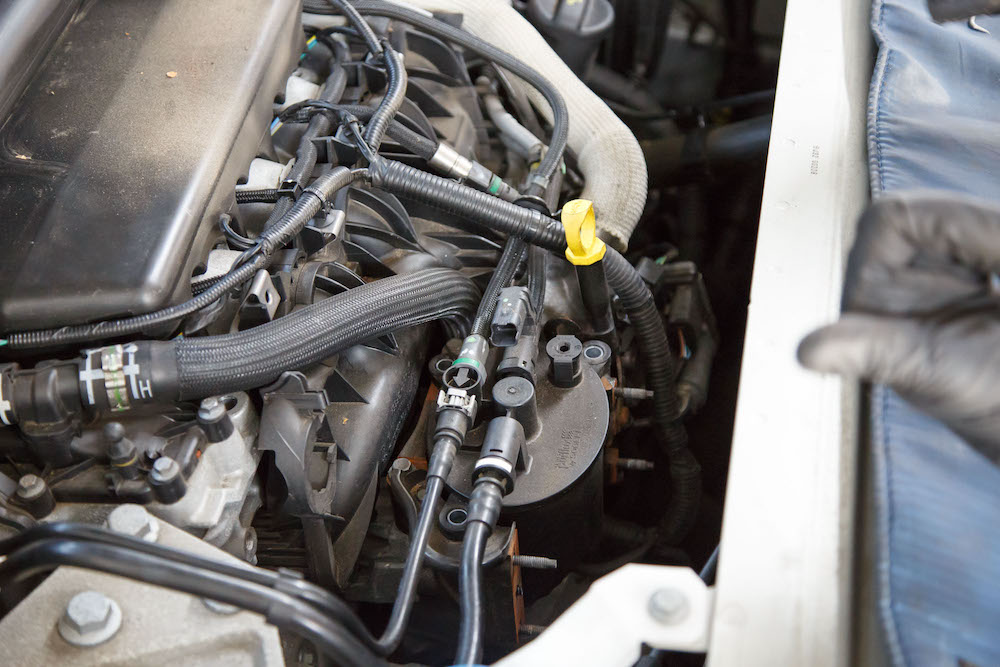

To diagnose a faulty crankshaft position sensor:

1. Check for diagnostic trouble codes (DTCs) using an OBD-II scanner. Common codes associated with a bad crankshaft position sensor include P0335 (Crank Position Sensor A Circuit Malfunction), P0336 (Crank Position Sensor A Circuit Range/Performance), and P0340 (Camshaft Position Sensor Circuit Malfunction).

2. Visually inspect the wiring harness for any signs of damage or corrosion. Make sure all connections are secure and free from corrosion or debris buildup.

3. Test the voltage output at the connector using a multimeter set to DC volts mode; refer to your vehicle’s service manual for specific voltage readings at different RPM ranges as well as acceptable tolerance levels for each range reading. If any readings are outside of these parameters then you may have found your problem.

4. Perform an ohmmeter test on both terminals to check resistance levels; again refer to your service manual for specific values at different RPM ranges as well as acceptable tolerance levels for each range reading; If any readings are outside these parameters then you may have found your problem.

To replace a faulty crankshaft position sensor:

- Disconnect the negative battery cable before beginning work on electrical components to avoid short circuits or other potential hazards while working on them; also make sure that all accessories such as air conditioning systems are turned off before disconnecting power cables from their respective components to avoid potential damage due to sudden power surges when reconnecting them later on during installation process.

- Locate the old CPS near its mounting point which should be easy enough since most vehicles will have it mounted close by either directly onto the engine block itself or nearby bracketry/support structures like the intake manifold etc…

- Remove the old CPS by unscrewing its mounting bolts with the appropriate size socket wrench/spanner set depending upon the type & size used originally during the installation process – Take note that some models may require special tools such as Torx bits etc. so make sure you’re prepared beforehand accordingly.

- Install new CPS into the same location where the old one was removed from – Use the same type & size bolts used originally during the installation process if possible otherwise, use the ones provided along with the new part itself – Tighten securely but not too tight so that there won’t be any issues later down line due over tightening causing unnecessary stress points within the system itself which could lead further complications down line…

- Reconnect the negative battery cable back into place, Once everything else has been installed correctly & securely, and tightened up properly – start the engine & check whether everything works fine without any issues present – If all looks good then the job is done successfully.

The Benefits of Installing an Aftermarket Crankshaft Position Sensor

The crankshaft position sensor is an important component of a vehicle’s engine management system. It monitors the position and speed of the crankshaft, providing data to the engine control unit (ECU) which then adjusts fuel injection and ignition timing accordingly. Installing an aftermarket crankshaft position sensor can provide numerous benefits for your vehicle.

- One benefit is improved performance. An aftermarket crankshaft position sensor can be more accurate than a factory-installed one, allowing for more precise fuel injection and ignition timing adjustments that result in better overall performance from your engine. This can also lead to improved fuel economy as well as reduced emissions from your vehicle.

- Another benefit is increased reliability. Aftermarket sensors are often made with higher-quality materials than factory-installed ones, making them less prone to failure or malfunction due to wear and tear over time. This means you won’t have to worry about unexpected breakdowns or costly repairs due to faulty sensors in the future. Not to mention, getting some crankshaft repairs done.

- Finally, installing an aftermarket crankshaft position sensor can also save you money in the long run by reducing maintenance costs associated with replacing worn-out factory-installed sensors regularly. With an aftermarket sensor installed, you won’t have to worry about frequent replacements or expensive repair bills down the line due to faulty parts or poor-quality materials used in manufacturing them.

Overall, installing an aftermarket crankshaft position sensor provides numerous benefits for your vehicle including improved performance, increased reliability, and cost savings over time through reduced maintenance costs associated with replacing worn-out factory-installed parts regularly.

Understanding the Different Types of Crankshaft Position Sensors Available

Crankshaft position sensors are an important component of any engine, as they provide the necessary information to the engine control unit (ECU) to ensure that the engine is running correctly. There are several different types of crankshaft position sensors available, each with its advantages and disadvantages.

Understanding these differences can help you choose the right sensor for your application.

- The most common type of crankshaft position sensor is a Hall effect sensor. This type of sensor uses a magnetic field to detect changes in rotational speed and angle, allowing it to accurately measure the position of the crankshaft about other components in the engine. Hall effect sensors are reliable and relatively inexpensive, making them a popular choice for many applications.

- Another type of crankshaft position sensor is an inductive pickup coil. This type uses an electromagnetic field generated by a coil wrapped around a metal core to detect changes in rotational speed and angle, similar to how Hall effect sensors work. Inductive pickup coils tend to be more expensive than Hall effect sensors but offer greater accuracy and reliability over time due to their robust construction.

- A third option is optical encoders, which use light-emitting diodes (LEDs) or laser beams directed at reflective surfaces on rotating parts such as gears or pulleys to measure rotational speed and angle with great precision. Optical encoders tend to be more expensive than both Hall effect sensors and inductive pickup coils but offer superior accuracy when measuring very small angles or speeds over long periods without any degradation in performance due to their robust construction and lack of moving parts that can wear out over time as other types do.

- Finally, there are also variable reluctance (VR) sensors available which use magnetically sensitive materials such as ferrite cores or iron powder cores wrapped around coils that generate electrical signals when exposed to changing magnetic fields created by rotating components such as gears or the crankshaft pulley within an engine’s crankcase assembly. VR sensors tend not to be used as often due to their lower accuracy compared with other types but they can still provide useful information about changes in rotational speed or angle if needed.

In conclusion, there are several different types of crankshaft position sensors available, each offering its advantages depending on your application needs. Understanding these differences will help you make an informed decision when selecting one for your particular project.

Troubleshooting Tips for Common Issues with the Crankshaft Position Sensor

The crankshaft position sensor is an important component of a vehicle’s engine, as it helps to monitor the rotational speed and position of the crankshaft. If this sensor malfunctions, it can cause a variety of issues with your vehicle’s performance. Here are some troubleshooting tips for common issues with the crankshaft position sensor:

1. Check for loose connections: The first step in troubleshooting any issue with the crankshaft position sensor is to check all connections and wiring for any signs of damage or looseness. Make sure that all wires are securely connected and that there are no frayed or broken wires.

2. Check for corrosion: Corrosion can also be a common issue when it comes to problems with the crankshaft position sensor. Inspect all connectors and terminals for signs of corrosion, which can prevent proper electrical contact between components and lead to malfunctioning sensors.

3. Replace faulty parts: If you have identified any faulty parts such as corroded connectors or broken wires, they should be replaced immediately to ensure the proper functioning of the crankshaft position sensor.

4. Clean contacts: In some cases, simply cleaning off dirt or debris from contacts may help resolve issues with your vehicle’s performance caused by a malfunctioning crankshaft position sensor. Use an appropriate cleaner such as rubbing alcohol on contacts before reconnecting them to ensure optimal performance from your vehicle’s engine components.

5. Test voltage output: Finally, if you suspect that there may be an issue with voltage output from your car’s computer, use a multimeter to test voltage output at various points along the circuit. This will help you identify whether there is an issue related specifically to voltage output, which could indicate a problem within either the computer itself or its connection points.

The Impact of a Faulty or Malfunctioning Crankshaft Position Sensor on Vehicle Performance

The crankshaft position sensor is an essential component of a vehicle’s engine management system. It is responsible for providing the engine control unit (ECU) with information about the position and speed of the crankshaft, which in turn allows it to adjust fuel delivery and ignition timing accordingly.

As such, a faulty or malfunctioning crankshaft position sensor can have a significant impact on vehicle performance.

- One of the most common symptoms associated with a faulty or malfunctioning crankshaft position sensor is difficulty starting the engine. This occurs because, without accurate information from the sensor, the ECU cannot accurately adjust fuel delivery and ignition timing to ensure that combustion takes place at precisely the right time. As such, it may take multiple attempts before enough fuel has been delivered to start up successfully.

- In addition to difficulty starting up, another symptom associated with a faulty or malfunctioning crankshaft position sensor is poor acceleration performance due to incorrect ignition timing and fuel delivery settings caused by inaccurate data from the sensor. This can result in reduced power output as well as increased emissions due to incomplete combustion of fuel in each cylinder stroke.

- Finally, if left unchecked for too long, a faulty or malfunctioning crankshaft position sensor can cause serious damage to other components within an engine’s management system due to incorrect data being sent through them resulting in misfiring cylinders and other issues that could lead to costly repairs down the line if not addressed promptly by qualified technicians using specialized diagnostic equipment.

In conclusion, it is clear that having a functioning crankshaft position sensor is essential for optimal vehicle performance as any faults or malfunctions can have serious consequences on both its operation and longevity over time if not addressed promptly by qualified technicians using specialized diagnostic equipment.

Smartphone-Enabled Diagnostics for Your Car’s Engine Components

The automotive industry is constantly innovating to make cars safer, more efficient, and easier to maintain. One of the latest developments in this field is smartphone-enabled diagnostics for car engines. This technology allows drivers to quickly and easily diagnose any issues with their engine components, including the crankshaft position sensor (CPS).

- Smartphone-enabled diagnostics use a specialized app that connects your phone to your car’s onboard computer system. Once connected, you can access detailed information about your engine’s performance and any potential problems it may be experiencing. The app will also provide you with step-by-step instructions on how to fix any issues that are detected.

- The CPS is an important component of the engine as it helps regulate ignition timing and fuel injection. If it fails or malfunctions, it can cause serious damage to other parts of the engine or even lead to a breakdown. With smartphone-enabled diagnostics, you can quickly identify if there are any problems with the CPS before they become serious enough to cause major damage or require costly repairs.

- In addition to helping diagnose issues with your car’s engine components, smartphone-enabled diagnostics also allow you to monitor other aspects of its performance such as fuel economy and emissions levels. This data can help you make informed decisions about when it’s time for regular maintenance or when certain parts need replacing to keep your vehicle running smoothly for years down the road.

Overall, smartphone-enabled diagnostics offer a convenient way for drivers to stay on top of their vehicle’s maintenance needs while avoiding costly repairs due to unexpected breakdowns caused by faulty components like the CPS. As this technology continues to evolve, we expect that more features will be added which further enhance its usefulness.

Comparing OEM vs Aftermarket Replacement Parts

When it comes to replacing your car’s crankshaft position sensor (CPS), you have two main options: OEM (Original Equipment Manufacturer) and aftermarket replacement parts. Both types of parts can be used to replace a faulty CPS, but which is best for your vehicle?

- OEM parts are designed and manufactured by the same company that made the original part in your vehicle. This means they are designed specifically for your make and model, so they will fit perfectly and work as intended. OEM parts also come with a warranty from the manufacturer, so if something goes wrong you can get it replaced or repaired at no extra cost. The downside of OEM parts is that they tend to be more expensive than aftermarket replacements.

- Aftermarket replacement parts are made by third-party companies that specialize in producing generic components that fit multiple makes and models of vehicles. These parts may not fit as precisely as an OEM part, but they usually cost less than their branded counterparts. Aftermarket replacement CPSs also typically come with a limited warranty from the manufacturer, although this may not cover all potential issues with the part itself or its installation process.

Ultimately, when deciding between OEM vs aftermarket replacement CPSs for your car, it’s important to consider both price and quality before making a decision. If you want peace of mind knowing that you have an exact match for your vehicle’s original part then an OEM CPS is probably worth the extra money; however if budget is more important then an aftermarket option might be better suited to meet your needs without sacrificing too much quality or reliability in the process.