One of several electrical components in a car is the camshaft position sensor (CMP). We’ll discuss what this component is, the camshaft sensor symptoms, and how much it will cost to repair it.

The camshaft is a crucial part of an automobile’s engine. The valves for the intake and camshaft position sensor exhaust are primarily controlled by it. Additionally, it might power the power steering pump, oil pump, and gasoline pump.

Given that the camshaft controls what is perhaps the most significant function in the car—determining the intake and camshaft position sensor exhaust rate—many symptoms may manifest if something is broken. It can be difficult to identify the camshaft from the crankshaft, not only because their names are similar but also because they function together.

- Camshaft Position Sensor

- Common Symptoms

- Where it is Located?

- Getting OBD Codes?

- How is it Diagnosed?

- Camshaft Sensor Replacement

- How Much Does It Cost?

- Sensor Bank 2

- Sensor Bank 1

- Camshaft vs Crankshaft

Camshaft Position Sensor

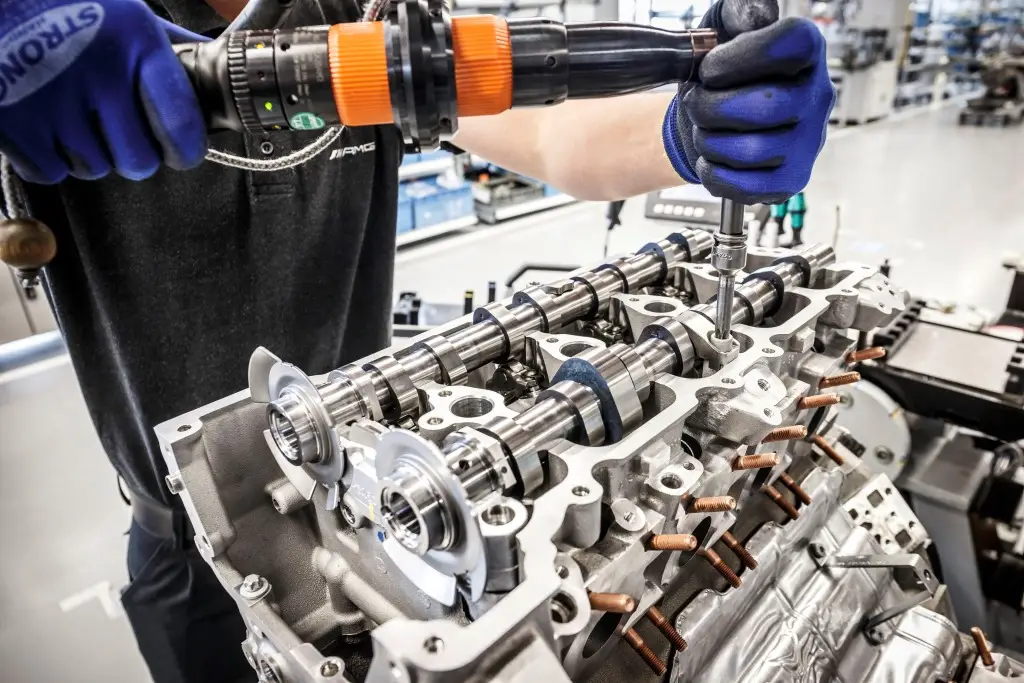

Two of the most crucial parts of an engine are the camshaft and the crankshaft. While the crankshaft regulates the pistons, the camshaft determines where the inlet and camshaft position sensor exhaust valves are located. The camshaft position sensor monitors the camshaft’s rotation and focuses on the opening and closing of valves.

Most camshaft sensors are situated directly above the notched ring of the camshaft. A crankshaft position sensor will be used in conjunction with the majority of these camshaft sensors to generate or modify an AC electrical signal, which will be used to determine whether a position is getting close to the top dead center (TDC) on the compression stroke.

Spark timing and injector pulse adjustments will benefit from this data. It is also known as a phase detector or a cylinder identification sensor. A sequential fuel injection system requires the ECU to choose which cylinder to ignite next.

This information is provided by the cylinder identification sensor. When the first cylinder is at the top dead center while the engine is turning, the sensor sends a signal to the onboard controller (TDC).

Camshaft Position Sensor Symptoms

When the camshaft position sensor malfunctions, you may typically notice a few camshaft position sensor symptoms. Watch out for these typical camshaft sensor symptoms:

Camshaft Sensor Symptoms #1: Low Fuel Efficiency

The engine control module will receive erroneous data from a malfunctioning camshaft position sensor. Your engine won’t be able to operate as efficiently as it should, which will result in it needing more fuel.

Camshaft Sensor Symptoms #2: Stalling

The engine may stall if the fuel injectors do not supply the right amount.

Camshaft Sensor Symptoms #3: Rough Idling

A malfunctioning camshaft position sensor may be to blame for a harsh idle engine. When the engine is idling, this problem is more noticeable.

Camshaft Sensor Symptoms #4: Hesitation

A malfunctioning camshaft sensor can cause hesitancy when accelerating, which is a common problem.

Camshaft Sensor Symptoms #5: Emissions Test Failure

A malfunctioning engine will not be able to burn fuel effectively. This can result in more emissions.

Camshaft Sensor Symptoms #6: Gas Smell

Your tailpipe may let unburned fuel escape, which may leave a gaseous aroma behind (which you can get more context in our guide on how to get gasoline out of clothes).

Camshaft Sensor Symptoms #7: Car Won’t Start

As the camshaft position sensor ages, the engine control module receives a weaker signal as a result. You won’t be able to start your automobile if the engine no longer gets the signal. Your engine may misfire if your camshaft position sensor isn’t functioning properly.

Camshaft Sensor Symptoms #8: Transmission Shifting

The information given to the engine control module can prevent the transmission from shifting correctly. There is a security feature in some cars that switches the automobile into “limp mode.” This lessens the chance of serious engine damage.

Camshaft Sensor Symptoms #9: Check Engine Light Is On

The check engine light will come on when your car has a problem. The light can be activated for a variety of reasons. Have your mechanic do a diagnostic scan as soon as possible if your dashboard warning light is on to identify the precise issue.

When it is safe to do so, pull over and turn off your car if the light is flashing. Request a tow. Don’t keep on driving your car.

Camshaft Position Sensor Location

The brand, type, and layout of the engine all affect where the camshafts are located precisely. However, it will be someplace near the camshaft. The camshaft position sensor is often found close to the front or top of the engine.

This can be found typically close to the timing cover on the intake manifold, the top of the cylinder block, one or both ends, or the intake manifold. The camshaft sensor may occasionally be located behind the timing cover. Simply remove the engine cover for the specific engine in question to observe that it is situated directly on the back of the engine for simplicity and ease of use.

Replaced Camshaft Position Sensor But Still Get Code

The camshaft sensor is employed in a number of various car parts. Two such consumers of the sensor are the Powertrain Control Module (PCM) and Engine Control Module. The PCM is utilized for fuel management and other engine control procedures, whereas the ECM controls ignition timing.

Engine timing issues can result in misfires and inadequate fuel-to-air mixes when the camshaft position sensor’s signal is disrupted. To alert the driver that something is incorrect, the PCM will issue a P0340 camshaft position sensor code and illuminate the Check Engine Light. There are many different parts of the car where the camshaft sensor is employed.

The sensor is consumed by the Engine Control Module and the Powertrain Control Module, or PCM. The PCM is utilized for fuel management and other engine control procedures, whereas the ECM controls ignition timing. Incorrect engine timing can lead to misfires and inadequate fuel-to-air mixes. This can be caused by disrupting the signal from the camshaft position sensor.

To alert the driver that something is incorrect, the PCM will issue a P0340 camshaft position sensor code and illuminate the Check Engine Light. They will lose power on the road if they keep driving the vehicle. Additionally, if you disregard this camshaft position sensor issue for an extended period of time, it may possibly harm the engine, necessitating a more costly repair method.

Causes Of The Issue

The camshaft position sensor itself is the most frequent cause of the P0340 error camshaft position sensor code. However, there are still further possible reasons, such as:

1. Circuit Issues

Electricity powers the camshaft position sensor. The P0340 error code may be set off if there is an issue with the electrical connector or wiring of the sensor. This code can be produced by damaged wires, sloppy connections, and poor grounds, among other things.

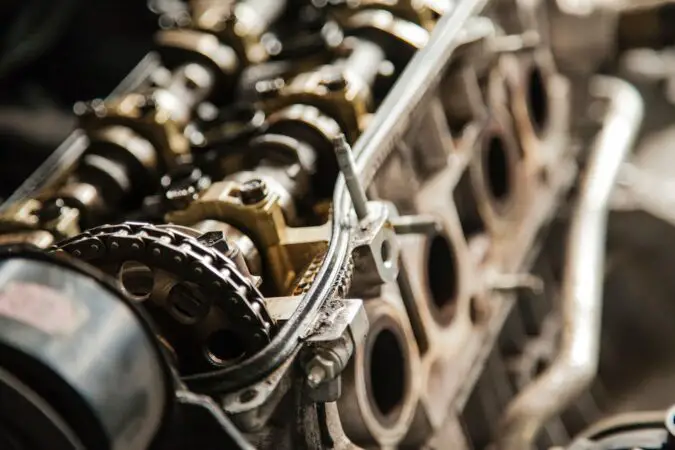

2. Camshaft Position Sensor Reluctor Wheel Damage

The notched wheel fastened to the camshaft is referred to as the reluctor wheel. This reluctor’s function is to bypass the sensor’s teeth and disrupt the magnetic field. The electric signal utilized by the PCM and ECM is then created as a result of this. The P0340 camshaft position sensor code may appear if this reluctor wheel is broken.

3. Defect In The Camshaft Position Sensor

Another possibility is a problem with the camshaft position sensor itself. In that situation, a replacement will be required. A new sensor is available online or at your neighborhood car parts store.

4. Problematic Starter Motor

A small electric motor called the starting motor is used to start the engine. Occasionally, the P0340 error code can be set off by a bad starter motor (you can diagnose further by learning how to tell if your starter is bad).

How Is Code P0340 Diagnosed

- Check for any trouble codes associated with this problem by connecting an OBD2 scanner. See if the code disappears by attempting to delete it.

- You would have a choice between two possibilities if the code appeared. It can be difficult to measure the camshaft position sensor if you’ve never done it before. Either the correct ohm values may be determined, or the signal can be checked using an oscilloscope to determine the camshaft position sensor A.

- Camshaft sensors may be easily and cheaply replaced. You must therefore decide if you are willing to take a chance. The most frequent reason for this error number is a faulty camshaft sensor.

- If the fault code reappears after measuring or replacing the sensor, you must measure and check the wiring between the engine control module and the sensor.

- Both the sensor and the engine control unit should be taken out of the car. Verify that there are no connections between the wires or to the ground.

- The failure of the engine control unit is the only possibility if the wiring is in working order. Before spending a lot of money on a new engine control unit, you should be certain that it is the issue. You can examine the 5v+, ground, and engine control unit signal if you’re a skilled mechanic.

Camshaft Sensor Replacement

Locating And Removing It

- Step 1: Find the sensor. The camshaft position sensor is typically installed in the block or cylinder head, depending on the engine architecture.

- Step 2: The negative battery cable should be disconnected. The negative battery cable should be disconnected and put aside.

- Step 3: Unplug the electrical connector for the sensor. Slide the electrical connector off by pressing down on the tab.

- Step 4: Take the sensor mounting screw out. Using a wrench or ratchet and socket of the proper size, remove the sensor mounting screws.

- Step 5: Take the sensor out. Pull the sensor straight out of the engine to remove it.

Replacing The Sensor

- Step 1: Replace the sensor. The bolt flange should be in line with the mounting hole as you push the sensor straight in.

- Step 2: Fasten the mounting screws for the sensor. Using a wrench or ratchet and socket of the right size, attach the sensor mounting screws and then tighten them down.

- Step 3: Replace the electrical connector.

- Step 4: Connect the negative battery cable again. Reconnect the battery’s negative terminal.

You’ll need to do that in order to replace your camshaft position sensor. If you think this is something you’d prefer to leave to a professional, your mechanic can provide skilled camshaft position sensor replacement.

Camshaft Sensor Replacement Cost

P0340 can be brought on by a variety of problems, including poor wiring, defective sensors, and defective ECM. You must first fully analyze the issue in order to provide an appropriate estimate. When you bring your car to a mechanic, the usual procedure is an hour of “diag time” (the time spent in labor diagnosing your specific issue).

Depending on the shop’s hourly cost, you should expect to pay anywhere from $75 and $150. If you hire a company to handle the job for you, the cost of the repairs frequently includes a diagnostic fee. From this point forward, a shop can estimate the cost of your P0340 code repairs.

Camshaft Position Sensor Test

A competent DMM can typically read both sides of the wave when the CMP sensor signal is idle because it has a low frequency. As a result, you might notice fluctuations in the voltage signal on your DMM display.

Testing A Magnetic Type CMP Sensor

- CMP sensors of the magnetic type generate their own AC (sine wave) signal. A digital multimeter (DMM) with the ability to measure AC (alternating current) voltage is required.

- Turn off the ignition to stop the engine from starting. To do this, cut the high-tension wire from the distributor cap, the ignition coil, and the ground wire from the wire and ground the wire to the engine block using a jumping wire. For this, an engine bolt or metal bracket can be used. Consult your car’s manual for repairs if necessary.

- Put the automatic transmission in Park or Neutral (manual).

- Set the emergency brakes.

- Switch off the CMP sensor.

- Select DC voltage on your multimeter.

- While the ignition is on and the engine is off, check for voltage at the harness connector. The voltage at the terminal may be close to 1.5 volts, depending on the model. Consult the repair manual for your car.

- Now set the AC voltage reading on your DMM meter.

- Your DMM leads should be connected to the sensor termination pins.

- Allow a few seconds for an aide to crank the engine.

- Check your multimeter’s voltage reading.

- Compare your findings to the requirements in your repair manual.

Camshaft Position Sensor Bank 2

If the powertrain control module detects an improper camshaft position, the OBD-II generic code P0392 is set. The PCM receives information about the position of the camshaft from the camshaft position sensor, a fixed component that employs the camshaft’s notches and an electromagnetic field.

The module can then accurately determine fuel delivery and ignition timing as a result of this. When the voltage is 10% higher than the value recommended by the manufacturer, the code is generated.

The P0392 code is frequently caused by:

- Electrical connectors, wires, or sensors might become grounded or shorted as a result of oil or motor fluid seeping into them.

- Failure of the camshaft sensor due to fluid leaks

- Failure of the crankshaft sensor PCM

A vehicle is in danger of a no-start condition when the P0392 code is recorded. The PCM interprets the camshaft as being at the incorrect location, resulting in unpredictable behaviors.

Even though it might only indicate poor engine performance, the problem must be fixed immediately. It might be caused by fluids that have leaked or are leaking, which is an issue that will only get worse and accelerate the deterioration of parts.

Camshaft Position Sensor Bank 1

A P0016 OBD-II generic code warns the driver that the crankshaft position sensor (CKP) signal is not being received by the bank 1 camshaft position sensor (CMP), which monitors camshaft rotation. The CMP sends the data to the vehicle’s Powertrain Control Module (PCM). In order to maintain efficient cylinder firing, the PCM uses that data to manage the fuel injectors for ignition timing.

The CKP transmits crankshaft position and engine RPM to the PCM, which once more uses the information to regulate fuel injection and ignition timing. Unfortunately, the PCM cannot effectively manage engine timing when the signal from either the CMP or CKP sensors is erroneous or malfunctioning, which causes problems with the engine starting and idling.

The camshaft position sensor is typically installed close to the cylinder head, placing the CMP in opposition to the timing rotor that is connected to the engine camshaft. Furthermore, the crankshaft position sensor can be situated on the fuel pump for some diesel applications, the flexplate/flywheel, or the crankshaft pulley (also known as the harmonic balancer).

What Causes P0016 Code

- Faulty or corroded connections or wiring

- CKP sensor problem

- CMP sensor problem

- Elongated timing chain

- Mechanical issues such as a jumping timing chain, a slipping reluctor ring on the crankshaft, or a slipping reluctor ring on the bank 1 exhaust camshaft

- The issue with the camshaft phaser

- An improper oil viscosity or partially blocked channels restrict the flow of oil to the phaser

- A restriction exists in the Oil Control Valve (OCV) filter

Because your camshaft and crankshaft aren’t aligned properly, this particular OBD-II fault code is considered to be serious. If the valves strike the pistons due to a timing chain fault involving guides or tensioners, engine damage may result.

Depending on the component that failed, operating the car for an extended period of time could result in other internal engine issues. The automobile will probably be difficult to start, and if it is started, the engine might stall.

Difference Between Camshaft And Crankshaft

Crankshafts convert linear power from the pistons into rotational power that may be sent to the wheels through the transmission. It is one of the most varied power distribution systems in your automobile since it also uses all that rotating power to turn on the accessories.

Your camshaft revolves as a result of the crankshaft’s rotation, which also turns the timing belt or chain. All of this rotational motion is used by your camshaft to continuously raise and lower your engine’s intake and camshaft position sensor exhaust valves. This timing must be precise; if your camshaft position sensor intake valve does not open appropriately, there will not be enough air to support ignition.

Fresh air entering the system will be challenging if the exhaust valve doesn’t open on schedule, allowing all the burned fuel and air nowhere to go. Modern engines also use camshaft position sensors to achieve the highest performance levels while maximizing fuel efficiency.

Their shapes are one of the biggest distinctions between the two. There are offset lobes all along the long, narrow camshafts. On the other hand, crankshafts are big and heavy. Despite being primarily spherical in shape, they are stocky and difficult to work with due to the offset attachment locations for the connecting rod.

Naturally, it’s not just about how they look; these are two completely different parts with two wholly different purposes. The function of a crankshaft and camshaft must be understood in detail.

The camshaft provides the rhythm that keeps everything operating as it should, while the crankshaft serves as a tool for delivering power. Although they are completely different parts, they are both essential to engine performance.

Frequently Asked Questions

What Does A Camshaft Do

The camshaft turns on the intake and exhaust valves of a cylinder. A first lobe will open the camshaft position sensor intake valve, while a second lobe will open the exhaust valve. The valves will open and close at the proper times when the shaft revolves.

How To Reset Camshaft Position Sensor

It’s obvious that a camshaft position sensor cannot be reset. As a result, if your camshaft is having troubles, you will need to replace the part (check engine light on, acceleration issues, sputtering and stalling, etc.)

What To Do After Replacing Camshaft Sensor

You should reprogramme the camshaft sensor with an OBD-II scanner to remove any error messages after replacing it. The engine computer will continue to get inaccurate signals from the old camshaft sensor if you don’t reprogram the new one, which could lead to cylinder misfire and other drivability problems.

What Sensors Can Cause A Car Not To Start

The following sensors are frequently responsible for a car not starting: the mass air flow sensor, oil pressure sensor, throttle position sensor, fuel pressure sensor, crankshaft position sensor, camshaft position sensor, and manifold absolute pressure sensor.

What Causes Crankshaft Sensor To Go Bad

There are a lot of things that can go wrong with the circuitry in the crankshaft position sensor, including corrosion, debris, and failure. The engine is a dangerous and damaging environment, even for contemporary electronics. Despite being designed for this, the heat and vibrations of the engine eventually cause most sensors to fail.

How To Check If Camshaft Position Sensor Is Bad

Numerous additional symptoms can point to a camshaft position sensor problem in your vehicle. Every time you start your automobile and every time you drive it, your engine stalls out. When you insert your key and turn it, your automobile completely won’t start. You press the gas pedal, your car struggles to accelerate as normal. When your automobile is started, you may tell that the cylinders in your engine aren’t firing properly. Your automobile suddenly starts getting incredibly poor gas mileage for no apparent reason.

How To Test Camshaft Position Sensor

Put the Ohms setting on your multimeter and touch the meter that leads to the sensor termination pins. If the resistance is infinite, the sensor is open and needs to be changed. You may encounter versions with resistance readings of 200 to 900 ohms. Consult the specifications in your repair manual.

What Does Camshaft Position Sensor Do

The camshaft position sensor is used to determine which cylinder is burning in order to synchronize the firing order of the fuel injector and coil.

Where Is The Camshaft Sensor Located

Usually found in the engine’s cylinder head, the camshaft position sensor includes a cylindrical component that inserts into the head.

What Happens When A Camshaft Sensor Goes Bad

A faulty camshaft position sensor starts to slow down data transmission. Your car will splutter, accelerate slowly, lack power, stall, or even shut off if the fuel delivery and ignition timing are out of sync by a few milliseconds.

How To Start A Car With A Bad Crankshaft Sensor

Clean the battery terminals after removing the cords. By doing this, you can help prevent corrosion and dirt buildup on the connections. Examine the spark plugs and wires in the engine. The crankshaft sensor could malfunction if they are worn out or damaged. With the engine’s throttle slightly open, try starting the vehicle. If the crankshaft sensor is unable to accurately detect the engine’s speed, this may be of assistance. Check for codes in the engine’s computer system. This can point out the issue’s root cause and direct you toward a fix. The crankshaft sensor should be replaced. If the sensor is indeed malfunctioning, this is typically the best option.

How To Replace Camshaft Position Sensor

The negative battery cable should be disconnected and put aside. Slide the electrical connector off by pressing down on the tab. A wrench or ratchet and socket of the proper size should be used to remove the sensor mounting screws. Pulling the sensor out of the engine straight away will remove it. The bolt flange should be in line with the mounting hole as you push the sensor straight in.

What Does A Crankshaft Position Sensor Do

The multipurpose sensor used to control ignition timing, gauge engine RPM, and gauge relative engine speed is the crankshaft position sensor. With this sensor, manual distributor timing is unnecessary.

What Are The Symptoms Of A Bad Crankshaft Position Sensor

Having trouble starting the car, experiencing sporadic stalling, and having the Check Engine Light come on are all symptoms of a bad crankshaft position sensor.

Final Conclusion…

The camshaft position sensor and crankshaft position sensor both serve very similar purposes. The engine control module in some cars might be able to make up for one by making up for the other. However, you should always pay attention to sensor indications to prevent any outcomes that could harm your engine.

The most crucial parts of the engine are the camshaft and crankshaft. Since both the crankshaft position sensor and the camshaft position sensor provide readings to the engine, a problem with either sensor could impact the readings and functionality of your engine. This article primarily describes the functioning, camshaft sensor symptoms, and cost of a defective camshaft position (CMP) sensor replacement.